Diamond Rotary Dressers

ROLL WITH THE BEST IN DRESSING TECHNOLOGY

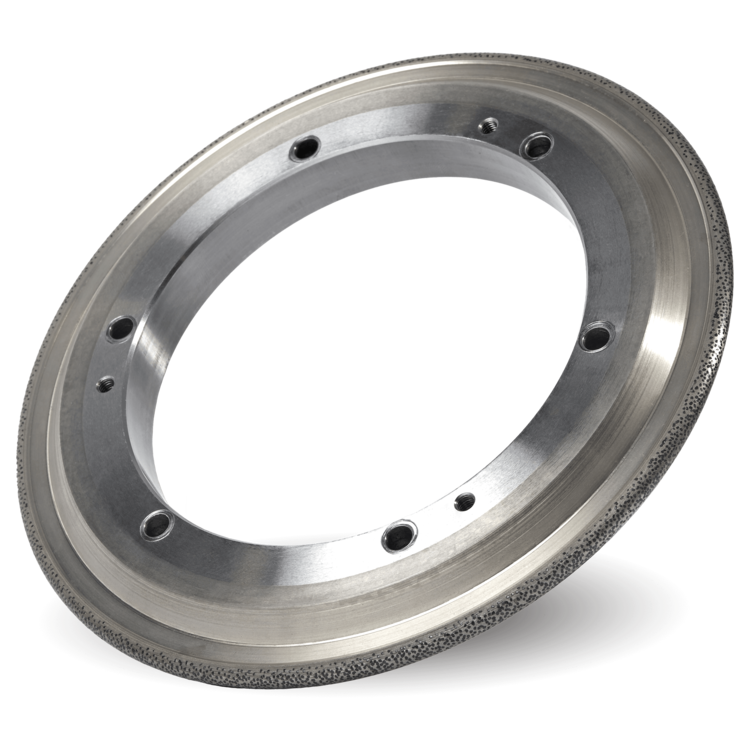

Disc Dressers Suitable for Basic Shaping to Intricate Profiling

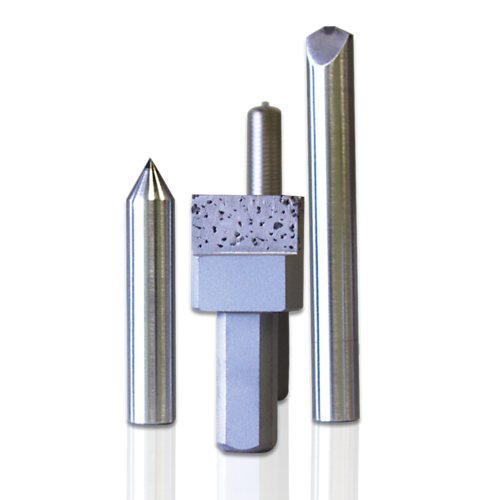

Plunge Dressers With Very Tight Tolerances On Form And Profile Line

Long Life For Production Applications

ABOUT Diamond ROTARY Dressers

Particle buildup covers surface abrasives over time, making them dull and ineffective. The diamond rotary dresser knocks off these particles, restoring balance and conditioning your wheel by returning abrasive grains to the surface, and also reducing thermal stress on the workpiece. CDT diamond dressers provide the ideal profile for your desired wheel topography, with superior strength and versatility.

What sets Continental Diamond Tool apart is the ability to custom manufacture dressers to meet even the most complex and exact configurations. We produce high quality rotary diamond dressers from a radius as small as 0.100mm and a profile of a line of 0.002mm. For most applications, we can manufacture and ship from our operations in North America or Europe, ensuring cost-effective solutions. When it comes to extending the performance and longevity of your superabrasive wheels, Diamond Rotary Dressers are far superior to anything you can achieve with a general purpose dresser.

All Rotary Dressers are manufactured within general tolerance of

0.003mm>0.003mm to bore

0.002mm to datum side face

0.002mm to bore

FOR YOUR COST SAVINGS AND CONVENIENCE 🇺🇸 🇬🇧 MOST OF OUR diamond rotary dressers CAN BE MANUFACTURED AND SHIPPED FROM NORTH AMERICA OR EUROPE.

Traverse Dressing

The dresser moves across or traverses the grinding wheel's surface to form its shape.

Ensures a uniform and precise wheel surface

Minimizes uneven wear for longer life

Enhances surface finish and quality

Suitable for basic shaping to intricate profiling

Plunge DRessing

The dresser makes a vertical movement, plunging the shape into the grinding wheel.

Ideal for achieving precise profile control

Used for shaping intricate workpiece profiles

Ensures maintenance of tight tolerances

Enables accurate, controlled material removal

The Consort Precision™ Name

Since 1984 Consort Precision Diamond Rotary Dressers have been revolutionizing grinding performance for industries worldwide. When Continental Diamond Tool Corporation acquired Consort Precision Diamond Company in 2018, CDT added its expertise and resources to this already award-winning, high-quality product line. Continental Diamond Tool produces Consort Precision diamond rotary dressers from a radius as small as 0.100mm and a profile line of 0.002mm. The dressers are still manufactured where this technology was first developed at the Continental Diamond Tool Limited facility in North Wales and at our high-tech manufacturing center in the United States. When it comes to extending the performance and longevity of your superabrasive wheels, Consort Precision Diamond Rotary Dressers are far superior to anything you can achieve with a general purpose dresser.

DIAMOND APPLICATION METHODS

ABRASIVE UTILIZATION

Below is a list of common applications for Diamond Rotary Dressers, but we find unique solutions for nearly any application. Supply our design team with the component and profile wishing to be dressed, along with grinding wheel information, and we will provide a drawing for approval. Contact us for a quote.

BY TOOL

Diamond Dressers — or diamond rolls —are a perfect companion for your Continental Diamond Tool grinding wheel, but our Diamond Rotary Dressers can be custom made for use with many brands of grinding wheel or other superabrasive tool, such as those made by:

Norton Abrasives

Radiac Abrasives Inc.

Abrasive Technology

3M Abrasives

Tyrolit

… and others.

BY INDUSTRY

Common industry applications include:

Aerospace

Aircraft

Automotive

Blade & Knife

Power Generation

Medical

Cutting Tools

Tool & Die

Saw

& Many Others

FREQUENTLY ASKED QUESTIONS

-

Diamond Rotary Dressers find extensive applications in a variety of industries, including:

• Aerospace

• Aircraft

• Automotive

• Blade and knife

• Power Generation

• Medical

• Cutting Tools

• Tool & Die

• Saw

& Many Others…

If you want to work to develop something new, CDT is excited to serve your manufacturing needs. Leveraging the best resources and latest technologies, we strive to get the job done right.

-

CDT experts are always available to help you with technical product support and offer guidelines for using the dressing tools we produce. However, here are some basic tips for your convenience:

Setup and Safety:

• Ensure the grinding machine is turned off before installation.

• Mount the rotary diamond dressing wheel securely on the grinder's spindle.

• Always wear appropriate personal protective equipment (PPE) and maintain a safe distance from the rotating wheel during operation.

Positioning and Alignment:

• Position the dressing wheel in proximity to the grinding wheel to be dressed.

• Ensure that the dressing wheel is properly aligned with the grinding wheel's surface.

• Adjust the angle and position as needed to achieve the desired profile on the grinding wheel.

Dressing Process:

• Turn on the grinding machine and allow it to reach its operational speed.

• Gently bring the rotary diamond dressing wheel into contact with the grinding wheel's surface.

• Maintain a consistent and steady feed rate to avoid uneven dressing.

• Observe the dressing process to ensure the desired shape and sharpness are achieved.

• Avoid applying excessive pressure, as this can cause premature wear of the dressing wheel.

Contact us with more specific questions.

-

The pricing at CDT depends on the type of diamond dresser and customization you require. Please connect with our sales team at +1-800-443-6629 (North America) or +44 1745-343951 (Europe) to get an accurate and no-obligation pricing quote today.

-

CDT holds ISO Certification and provides warranty coverage for all products. However, here are some tips to maintain the longevity of your investment:

• Use a coolant or lubricant to prevent excessive heat buildup during dressing.

• After dressing, disengage the dressing wheel, turn off the grinding machine, and clean any residual debris or dust from the dressing process to extend the life of your equipment.

• Store the rotary diamond dressing wheel in a safe and dry place when not in use to prevent damage or contamination.

To know more, get in touch with our CDT representative via call or email in case of significant wear or damage.