Diamond Rotary Dressers

ROLL WITH THE BEST IN DRESSING TECHNOLOGY

Disc dressers for basic shaping to intricate profiling

Plunge dressers with very tight tolerances on form and profile line

Long life for production applications

Engineered solutions by CDT and its partners

Effective February 11, 2026, CDT is the official representative for DR. KAISER products in North America.

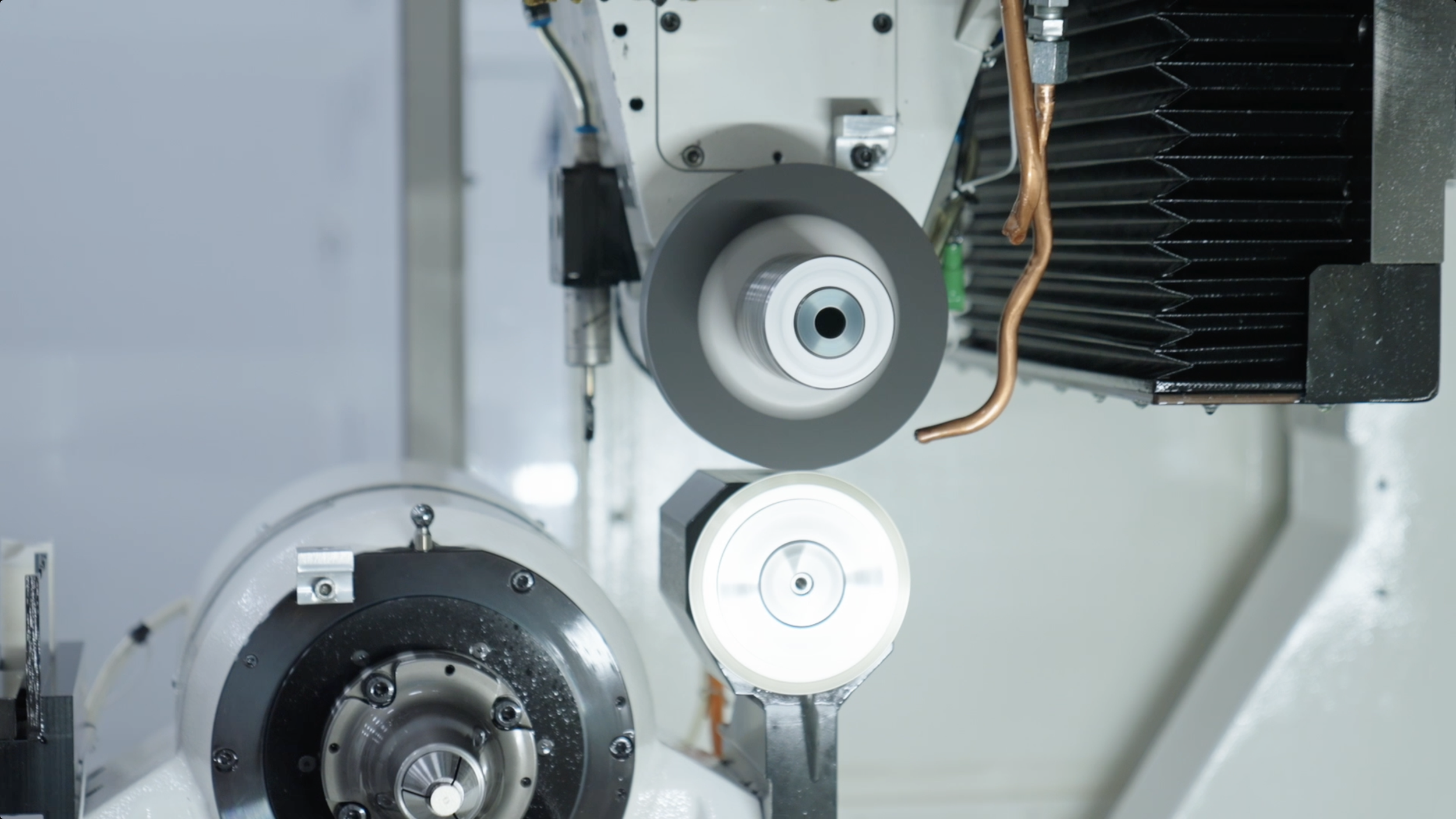

ABOUT Diamond ROTARY Dressers

Diamond rotary dressers play two critical roles in maintaining grinding performance over time: dressing the wheel to expose fresh abrasive grains and truing the wheel to restore and maintain its intended shape. Together, these functions support:

Accurate profile geometry

Consistent surface finish

Reduced thermal load on the workpiece

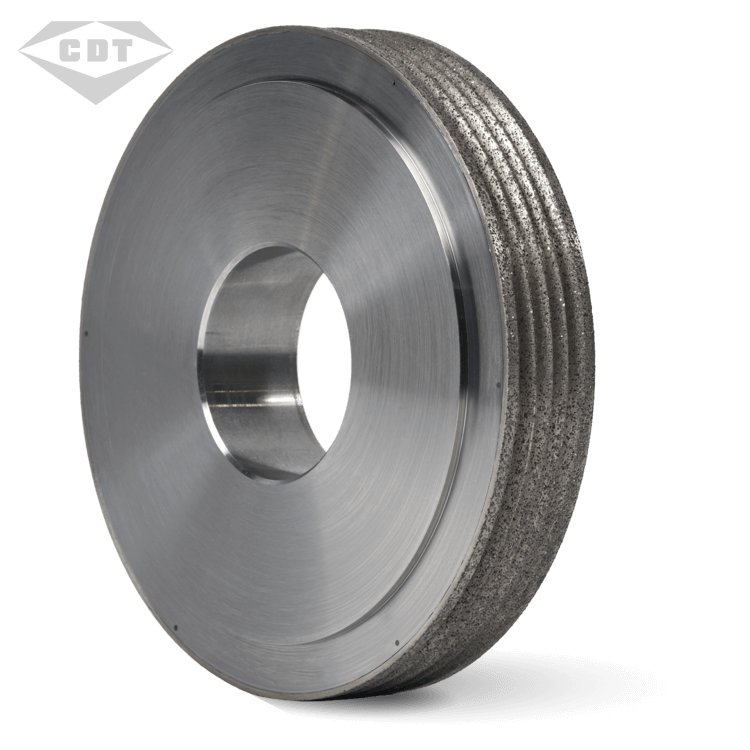

PLUNGE DRESSING with profile rollers

Plunge dressing is used when maximum form control and speed are required. The dresser moves vertically, plunging the shape into the grinding wheel.

Precise profile control for intricate workpieces

Tight tolerances on form and profile

Accurate, controlled material removal

Short dressing times and long dressing intervals

This type of diamond rotary dresser may be reverse plated or sintered.

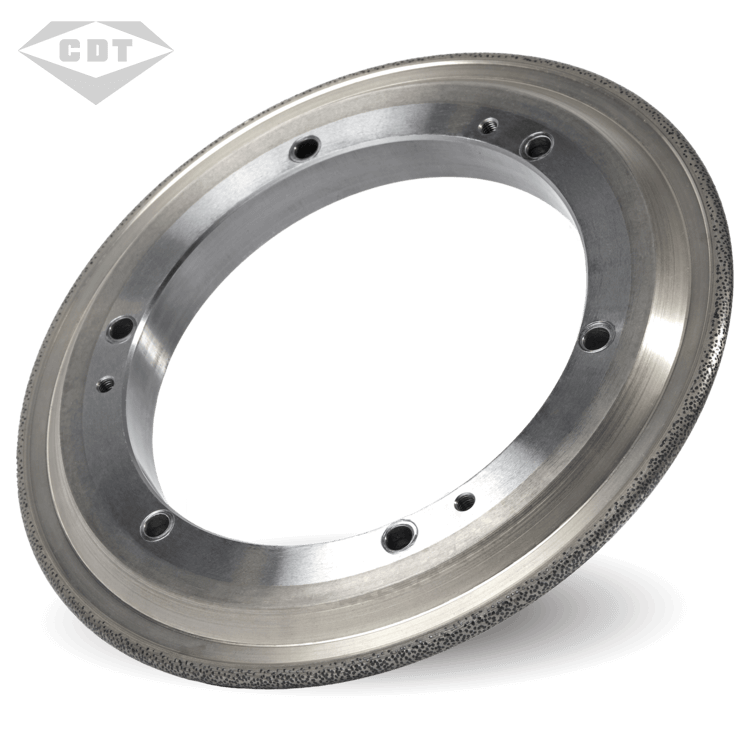

Traverse Dressing with dressing discs

Traverse dressing offers the most flexibility as the dressing disc is programmed to move laterally across the grinding wheel to form its shape.

Uniform wheel conditioning for improved finish

Extended service life with repairable options

Flexibility for complex contours and wheel forms

Economical self-sharpening impregnated discs

This type of diamond rotary dresser is typically sintered and often reinforced with CVD.

MANUFACTURING METHODS

YOUR DRESSING SOLUTIONS PARTNER

Continental Diamond Tool supplies custom diamond rotary dressers for a wide range of industries. Through global manufacturing capabilities and strategic partnerships, CDT provides access to multiple rotary dresser technologies—supported by CDT’s established network of sales and application engineers.

Continental diamond tool limited

CDT-Manufactured Diamond Rotary Dressers

Our diamond rotary dressers are engineered with decades of expertise at our subsidiary Continental Diamond Tool Limited, formerly known as Consort Precision Diamond Company. The team in North Wales pioneered the modern reverse-plating process for rotary dresser technology, establishing a foundation for today’s high-precision, form-critical dressing applications.

Manufacturing diamond rotary dressers since 1984

Plunge-style and traverse-style developed and produced in North Wales

Custom profiles with radii as small as 0.100 mm

Profile lines as fine as 0.002 mm

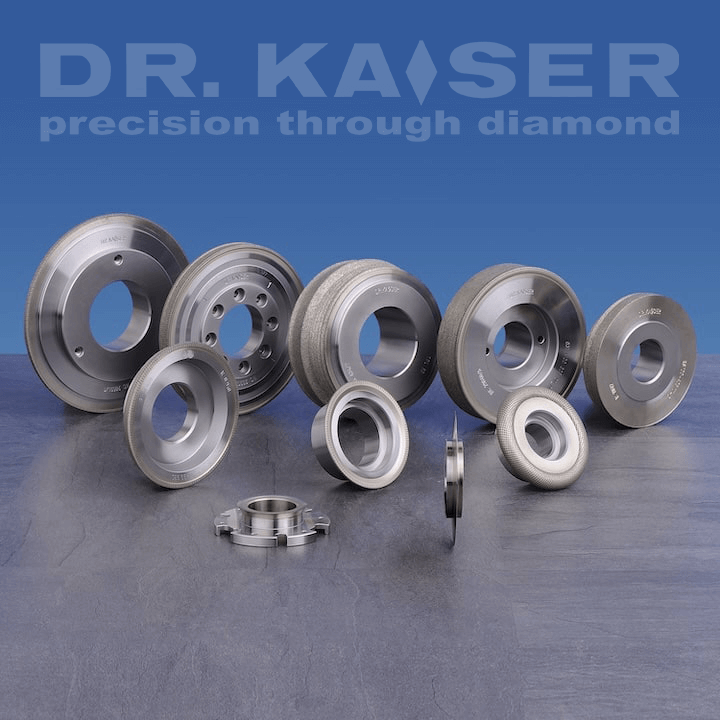

DR. KAISER DIAMANTWERKZEUGE GmbH & Co. KG

CDT represents DR. KAISER products in North America.

Founded in Germany in 1978, DR. KAISER Diamantwerkzeuge GmbH & Co. KG is the inventor of the dressing disc and a recognized leader in dressing technology. Their product portfolio supports a wide range of grinding processes and machine platforms.

Pioneers in dressing disc technology

Maximize precision and speed with single-axis profile rollers

Pair with DR. KAISER roll extractors for safe and efficient tool removal while protecting spindle bearings and sensitive diamond coatings.

ABRASIVE UTILIZATION

Below is a list of common applications for Diamond Rotary Dressers, but we find unique solutions for nearly any application. Supply our design team with the component and profile wishing to be dressed, along with grinding wheel information, and we will provide a drawing for approval. Contact us for a quote.

BY TOOL

Diamond Dressers—also referred to as diamond rolls—are a natural companion for conventional abrasive or CBN grinding wheels specified through Continental Diamond Tool. However, CDT diamond rotary dressers can be custom manufactured for use with a wide range of grinding wheel types, including those produced by:

Norton Abrasives

Radiac Abrasives Inc.

Abrasive Technology

3M Abrasives

Tyrolit

… and others.

BY INDUSTRY

Common industry applications include:

Aerospace

Automotive

Blade & Knife

Power Generation

Medical

Cutting Tools

Tool & Die

Saw

& Many Others

FREQUENTLY ASKED QUESTIONS

-

Diamond Rotary Dressers find extensive applications in a variety of industries, including:

• Aerospace

• Aircraft

• Automotive

• Blade and knife

• Power Generation

• Medical

• Cutting Tools

• Tool & Die

• Saw

& Many Others…

If you want to work to develop something new, CDT is excited to serve your manufacturing needs. Leveraging the best resources and latest technologies, we strive to get the job done right.

-

CDT experts are always available to help you with technical product support and offer guidelines for using the dressing tools we produce. However, here are some basic tips for your convenience:

Setup and Safety:

• Ensure the grinding machine is turned off before installation.

• Mount the rotary diamond dressing wheel securely on the grinder's spindle.

• Always wear appropriate personal protective equipment (PPE) and maintain a safe distance from the rotating wheel during operation.

Positioning and Alignment:

• Position the dressing wheel in proximity to the grinding wheel to be dressed.

• Ensure that the dressing wheel is properly aligned with the grinding wheel's surface.

• Adjust the angle and position as needed to achieve the desired profile on the grinding wheel.

Dressing Process:

• Turn on the grinding machine and allow it to reach its operational speed.

• Gently bring the rotary diamond dressing wheel into contact with the grinding wheel's surface.

• Maintain a consistent and steady feed rate to avoid uneven dressing.

• Observe the dressing process to ensure the desired shape and sharpness are achieved.

• Avoid applying excessive pressure, as this can cause premature wear of the dressing wheel.

Contact us with more specific questions.

-

The pricing at CDT depends on the type of diamond dresser and customization you require. Please connect with our sales team at +1-800-443-6629 (North America) or +44 1745-343951 (Europe) to get an accurate and no-obligation pricing quote today.

-

CDT holds ISO Certification and provides warranty coverage for all products. However, here are some tips to maintain the longevity of your investment:

• Use a coolant or lubricant to prevent excessive heat buildup during dressing.

• After dressing, disengage the dressing wheel, turn off the grinding machine, and clean any residual debris or dust from the dressing process to extend the life of your equipment.

• Store the rotary diamond dressing wheel in a safe and dry place when not in use to prevent damage or contamination.

To know more, get in touch with our CDT representative via call or email in case of significant wear or damage.