News and Resources

Browse by Category

Browse by Product

- All Dressing Products

- All Grinding Products

- CBN-Diamond Superabrasives

- Conventional Abrasives

- Diamond Lapping Compounds

- Diamond Rotary Dressers

- Diamond Stationary Dressers

- Hybrid Bond Grinding Tools

- Metal Bond Grinding Tools

- Plated Grinding Tools

- Resin Bond Grinding Tools

- Vitrified Bond Grinding Tools

Continental Diamond Tool Ltd. Moves Toward £1 Million Milestone with Poland Expansion Plans

CDT moves toward a £1 million milestone with plans to open a Poland branch supported by major manufacturing expansion in North Wales.

Continental Diamond Tool Ltd. (CDT) is preparing to establish a new branch in Poland as we move toward a £1 million sales milestone just months after announcing our sales presence there.

Since we first shared news of CDT’s growing activity in Poland in May 2025, demand in the region has continued to increase. Mariusz Kowalski, Sales Manager for Poland, plays a key role in developing new customer relationships and expanding CDT’s footprint within Poland’s fast-growing advanced manufacturing sector from his office near Warsaw.

The rapid growth in Poland comes alongside a major expansion of our operations in Kinmel Bay, where we have opened a new 30,000 sq ft factory on the Tir Llwyd Industrial Estate — three times the size of our previous site located just half a mile away.

The move is part of a £4 million investment that will see our workforce increase from 48 to 80 over the next couple of years. The expansion is enabling us to keep pace with strong global demand for our ultra-precision tools, used in industries ranging from aerospace and automotive to medical and steel manufacturing.

Poland’s Advanced Manufacturing Sector

General Manager Troy Giacherio said foreign markets would be a vitally important area for growth for CDT, especially in Poland, which in recent years has become a manufacturing powerhouse, with its aerospace industry especially strong.

“We expect to be at £1 million in sales in Poland — that is our goal by the end of this year. The country is just a booming market for industry.

“I would say the market potential there is probably well over £10 million for the products we manufacture here.

“A lot of companies and some huge customers are moving plants to Poland and expanding operations.

“As a result, we are looking to open a branch of the business in Poland which will be supplied from Kinmel Bay.

“It will make the logistics of shipping products in and out of Poland so much easier.”

Troy said the new distribution operation in Poland will likely create a couple of jobs initially and added:

“Obviously as our customer base expands and sales grow, depending on the market there, we might add additional sales staff.

“Depending on the customers and their requirements we might have to open up a space where we actually stock or store products there.

“That will make the trade and the movement of tools so much smo

Strategic Investment in North Wales

Continental Diamond Tool in Kinmel Bay manufactures electroplated grinding wheels and diamond rotary dressers for high-precision manufacturing applications.

The factory was first established in 1984 as Consort Precision Diamond Company, focusing on the production of reverse plated rotary dressing tools. In 2018, the business was acquired by Continental Diamond Tool Corporation, headquartered in New Haven, Indiana, and rebranded. Today, CDT designs and sells precision tools used to machine advanced materials including ceramics, composites and carbide.

Production Manager Justin Hughes emphasised the dedication of the staff, which has been key to the successful growth and expansion of the North Wales operation. He added:

“We are a very skill-dependent business so without our people, none of this would be possible.

“The expansion and sales growth give our workers security — the larger the company becomes, the stronger the long-term prospects.

“Better prospects and growth opportunities also help us attract great people.”

As we expand our capabilities and workforce in Kinmel Bay, we are always eager to hear from talented individuals who want to be part of a growing advanced manufacturing operation. Those interested in joining our team can visit our Careers page to submit a general application.

Ministerial Visit Highlights Progress

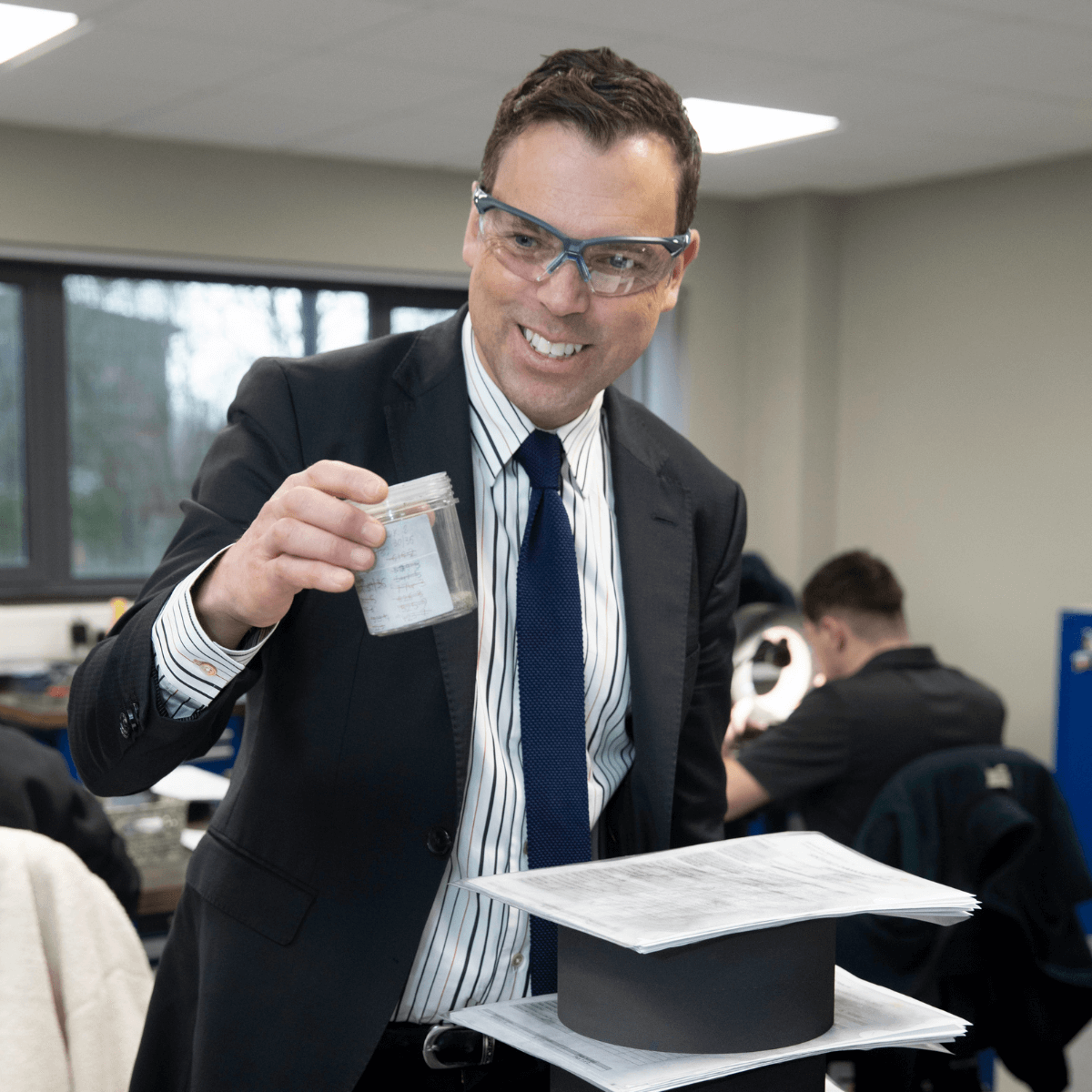

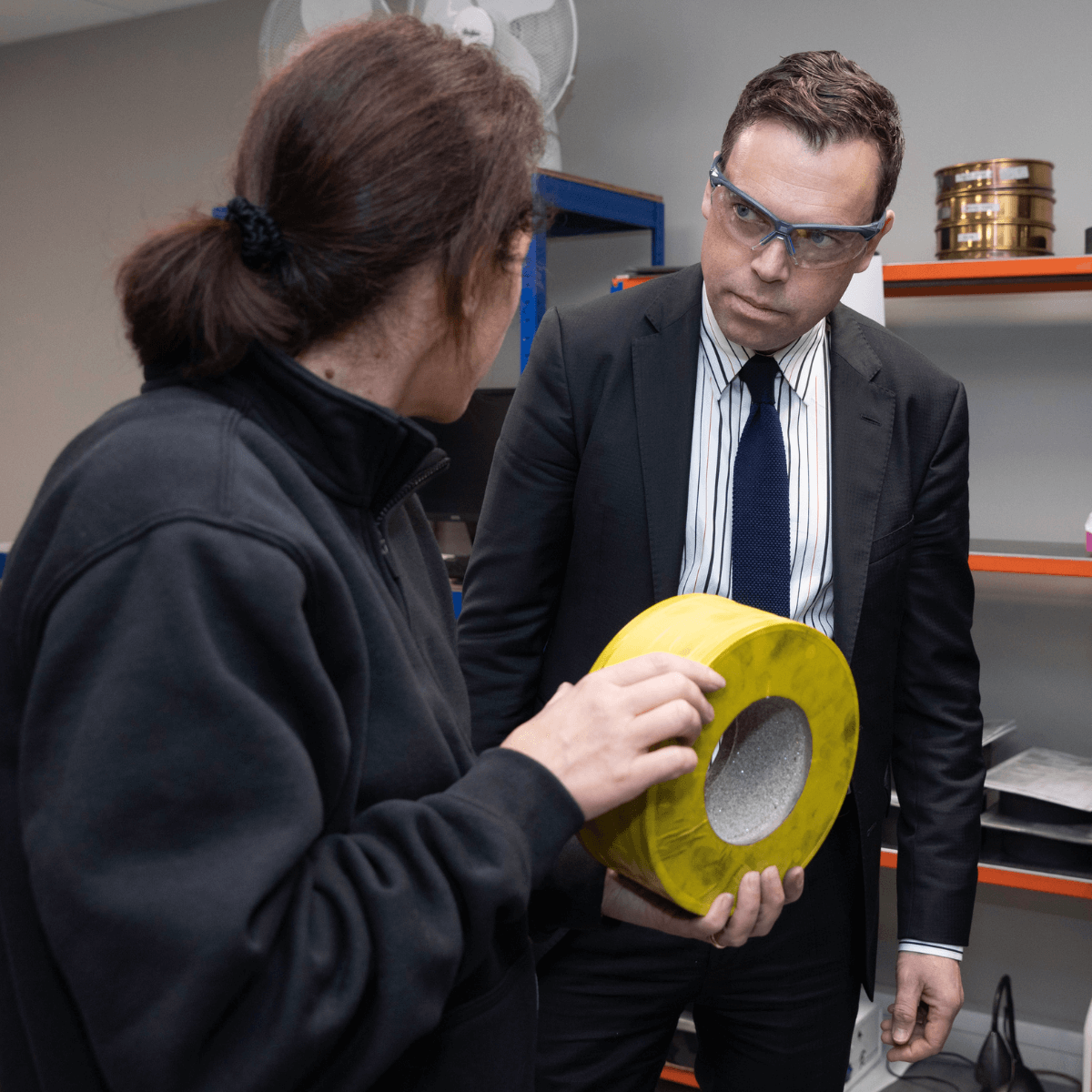

We were pleased to welcome Ken Skates MS, the Welsh Government’s Cabinet Secretary for Transport and North Wales, to our Kinmel Bay facility during a recent ministerial visit in January.

During the visit, General Manager Troy Giacherio and Production Manager Justin Hughes outlined CDT’s continued growth and expansion plans. Sales Manager Craig Cox provided a presentation updating Mr Skates on the company’s future ambitions in Poland, followed by a tour of the site.

Mr Skates had previously met CDT leadership during a visit to our former site in 2019. He was hugely impressed by what he had seen at the new hi-tech site in January.

He said:

“The phenomenal progress that has been made here is just remarkable.

“Since I last visited, we have seen incredible expansion and we have seen the future of this company become even brighter.

“It is an exemplar employer and is a great business in advanced manufacturing, utilising very high levels of skills and capturing some really big deals around the world.”

During his visit, Mr Skates met with our management team to discuss how the Welsh and UK governments could help support CDT’s growth.

He continued:

“What we all appreciate I think is the importance of economic and political stability, and enhanced skills training to make sure young people are introduced to the world of work earlier in life.

“We also need to be making sure that the basics are in place — making sure that the area is attractive for people to move to, making sure that transport infrastructure and the transport network meets people’s needs, these things are just fundamental.”

Next Step in Poland: ITM Industry Europe 2026

As part of our continued commitment to the Polish market, Continental Diamond Tool Ltd. will exhibit at ITM INDUSTRY EUROPE 2026, taking place May 26–29, 2026 in Poznań, Poland.

If you are planning to attend, we invite you to visit our stand to see firsthand how CDT’s custom superabrasive grinding wheels, rotary dressers, and other solutions for precision grinding can help solve your toughest applications. We are pleased to offer complimentary tickets to customers and partners. Simply reach out to our sales team to arrange yours in advance.

January 2026

Ken Skates MS, Cabinet Secretary for Transport and North Wales (center), visited our Kinmel Bay facility and met with CDT leadership — (from left) Sales Manager Craig Cox, Production Manager Justin Hughes, General Manager Troy Giacherio, and Finance Manager Christopher Richards — in January. While there, he met with CDT leadership before touring the site and speaking with team members across the operation.

Continental Diamond Tool Limited (CDT Ltd.), based in Kinmel Bay, Rhyl, U.K., is the European subsidiary of Continental Diamond Tool Corporation, headquartered in New Haven, Indiana, U.S.A. For more than 40 years, CDT Ltd. has been a leader in diamond rotary dresser technology, originally operating as Consort Precision Diamond. Since joining CDT, the company has expanded its product line, delivering high-performance diamond plated grinding wheels and other premium superabrasive products to customers worldwide.

Related Links:

https://businessnewswales.com/north-wales-engineering-firm-looks-towards-1m-milestone-with-poland-expansion-plans/

https://www.wales247.co.uk/north-wales-engineering-firm-targets-1m-sales-with-expansion-plans

https://nation.cymru/news/welsh-manufacturer-eyes-polish-branch-as-sales-near-1m/

https://www.baysideradio.co.uk/news/kinmel-bay-engineering-firm-eyes-1m-poland-boost-11730

https://www.rhyljournal.co.uk/news/25857639.kinmel-bay-engineering-firm-targeting-1-million-sales/

Crankshaft Grinding Fundamentals

Learn the fundamentals of crankshaft grinding, including plunge and vector grinding methods for main and rod journals in automotive manufacturing.

Crankshaft grinding is a complex, multi-step process that can include both cylindrical and surface grinding operations. What makes this type of grinding unique is that the grind itself plays a critical role in crankshaft performance.

In this episode of The Grinding Chronicles, CDT Engineering Consultant Jon VanSant walks through the anatomy of a crankshaft and explains the grinding methods used to produce high-performance results. Watch the video or read on for a breakdown of the processes involved.

The Grinding Chronicles – Episode 14

The Critical Role of Grinding in Crankshaft Performance

In crankshaft manufacturing, grinding isn’t just another machining step — it’s where the final component takes shape.

The size, roundness, and surface finish are all set during grinding. The relationship between the different features of the crankshaft is also defined at this stage. Because the crankshaft is responsible for turning the up-and-down motion of the pistons into rotational motion, those elements have to work together accurately.

Unlike some components that can be adjusted later, a crankshaft depends on the precision achieved during grinding. The form and surface condition established in this process directly affect how the crankshaft runs in the engine.

That’s why crankshaft grinding is considered one of the more demanding precision grinding applications in automotive manufacturing.

Understanding the Anatomy of a Crankshaft

Before discussing the grinding process, it’s important to understand the features that make up a crankshaft.

At one end of the shaft is the post, where a pulley will be attached. At the other end is the flange, which mounts to the flywheel.

Along the shaft are two primary journal types:

Main bearing journals (Mains) are located along the centerline of the crankshaft. These journals support the crankshaft within the engine block. One of the mains includes thrust walls to limit axial motion.

Rod journals (Crankpin journals) are positioned at equal distances around the shaft. These journals convert rotational motion into the up-and-down movement that drives the pistons.

Each rod journal is paired with counterweights, which balance the rotating assembly and counteract the motion of the connecting rods.

Every one of these features requires precision grinding, and each presents unique challenges.

Grinding Methods for Rods and Mains

Depending on the machine tool and production strategy, rods and mains may be ground together or separately. Two common grinding approaches are full form plunge grinding and vector grinding.

Full Form Plunge Grinding

In full form plunge grinding, the grinding wheel is dressed to match the exact contour of the finished journal. The wheel plunges straight into the rotating crankshaft journal to its final depth, then retracts.

Because the wheel already contains the final form, this method can be efficient and repeatable in high-volume production environments.

Vector Grinding

Vector grinding uses a narrower grinding wheel to grind both rod and main journals, despite the fact that rod journals are typically wider.

Instead of plunging straight in, the wheel:

Moves down one side of the journal

Traverses across the surface

Interpolates the radius

Side-grinds on exit

This motion is more dynamic, with the machine interpolating angles and tracing radii almost like a lathe operation. The benefit is flexibility: you can grind multiple journal widths using a single wheel specification.

Grinding the Thrust Wall

The thrust wall—located on one of the main bearing journals—controls axial movement within the engine. Most thrust walls are plunge ground. However, in some cases, the machine may traverse and side-grind into the wall to achieve the final width. From a finished-part perspective, both approaches can achieve the same result. The difference lies in how the machine tool executes the motion:

Vector-style interpolation moves at angles while tracing the radius.

Side grinding feeds straight in using the side of the wheel.

Understanding the machine’s motion is essential when selecting the appropriate grinding wheel specification.

Post and Flange Grinding

Post and flange grinding are typically plunge operations performed with the wheel head oriented at a 30-degree angle to the shaft.

During this process, the wheel feeds in from the end of the crankshaft, grinding both the outer diameter (OD) and the face simultaneously. This combined OD and face grinding requires stability, precision, and proper wheel selection to maintain geometry and surface integrity.

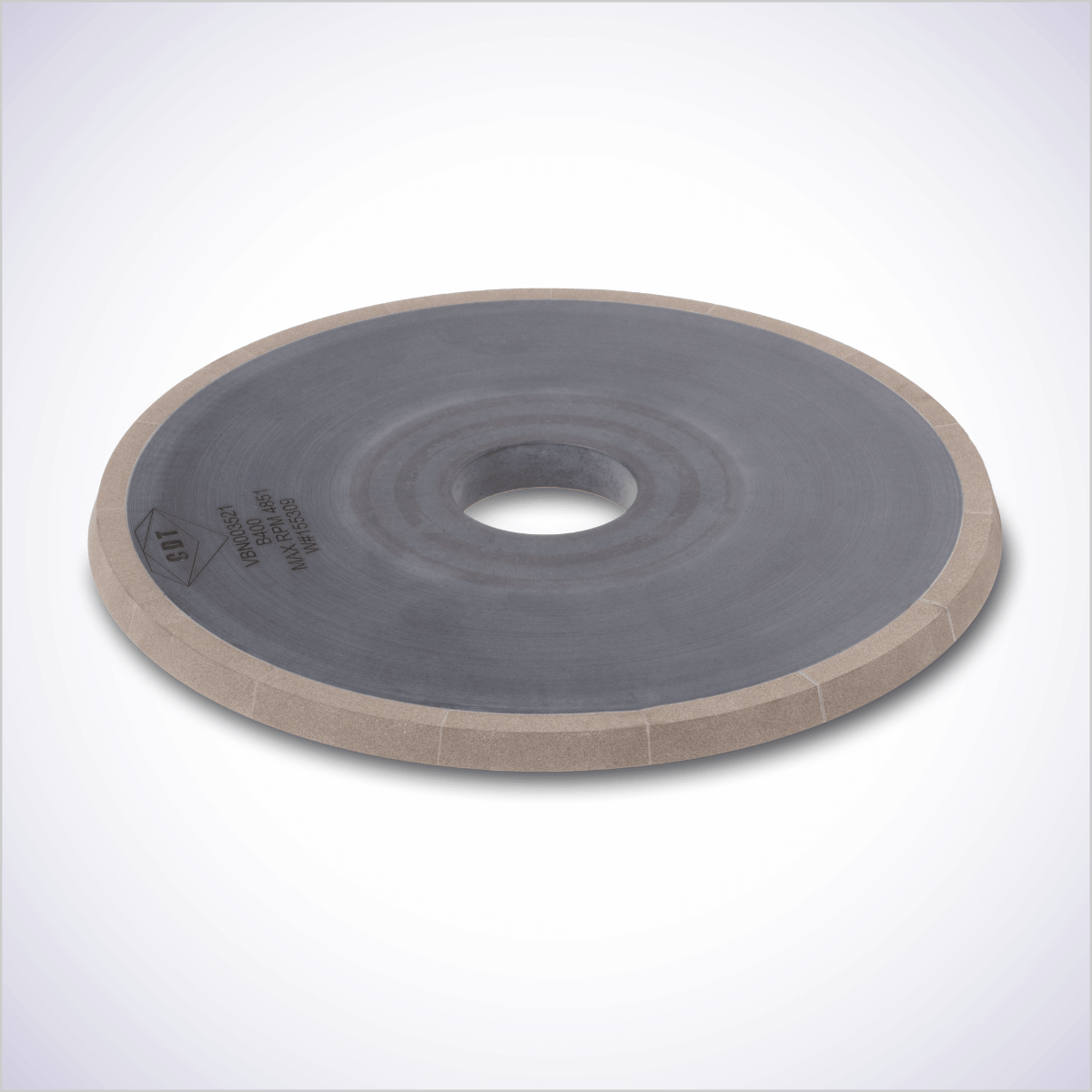

Grinding Wheel Technology in Crankshaft Applications

Historically, crankshaft grinding was commonly performed using conventional aluminum oxide grinding wheels, and those wheels are still used in certain applications today.

However, much of the industry has transitioned to vitrified CBN grinding wheels for hardened steel crankshafts. Vitrified CBN wheels offer improved form retention and consistency, particularly in high-volume production where maintaining journal geometry is critical.

Regardless of whether a process uses conventional wheels or vitrified CBN wheels, both rely on rotary diamond dressers to maintain wheel profile and keep the grinding surface properly conditioned. Optimized dressing intervals ensure that the wheel continues to generate the required journal form throughout the production cycle.

Machine Footage Courtesy of Fives landis Corp.

This episode features crankshaft grinding footage from Fives Landis Corp., part of Fives Group’s Grinding | Ultra Precision business line. The video showcases operations on the Landis LT2e, Landis LT2HHe, and Landis 3LVe platforms.

We appreciate Fives for allowing us to include this footage and highlight these machines in action. If you’re interested in learning more about their grinding platforms and manufacturing solutions, you can visit their website at:

Optimizing Your Crankshaft Grinding Process

At CDT, we have extensive experience supporting crankshaft grinding applications—from wheel specification to process optimization. If you have questions about your current crankshaft grinding wheels or are looking to improve cycle time, wheel life, or part quality, our engineering team is here to help.

📧 Contact us at TheGrindingChronicles@cdtusa.net or visit cdtusa.net/the-grinding-chronicles for more insights into precision grinding.

🔔 Follow CDT on LinkedIn and YouTube for future episodes of The Grinding Chronicles and news on the latest in grinding technology.

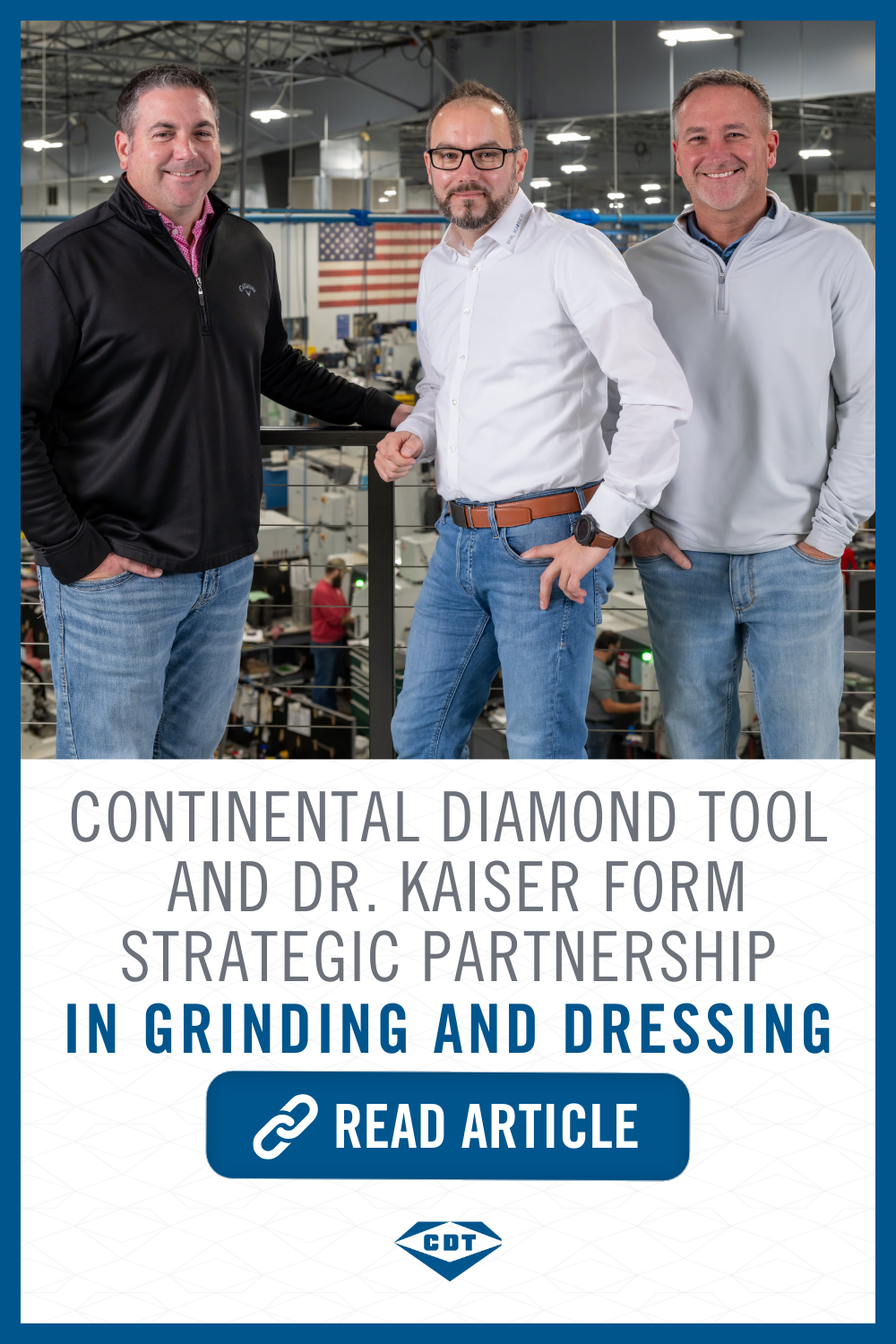

Continental Diamond Tool and DR. KAISER Form Strategic Partnership in Grinding and Dressing

CDT now represents DR. KAISER in North America, expanding access and service for their grinding, dressing, spindle, and wear protection products.

Continental Diamond Tool (CDT) and DR. KAISER DIAMANTWERKZEUGE GmbH & Co. KG are pleased to announce a strategic partnership between these two long-standing leaders in grinding and dressing technology. Under the agreement, effective Feb. 11, 2026, Continental Diamond Tool will represent DR. KAISER products throughout North America, including the United States, Canada and Mexico. After 30 successful years of representation, S.L. Munson is now supporting a seamless transition for customers to CDT as the new DR. KAISER representative. The new strategic agreement includes that DR. KAISER will offer CDT’s diamond and CBN grinding wheels across Central Europe and Turkey to complement the existing portfolio.

Watch the video below or read on for details.

A Unified Approach to Grinding and Dressing

The partnership between Continental Diamond Tool (CDT) and DR. KAISER combines world-class superabrasive technology with responsive, application-driven support for grinding operations worldwide. Both companies trace their roots to the 1970s and have grown alongside the adoption of industrial diamond and CBN abrasives in modern manufacturing. Today, each has evolved into a solutions provider—recognizing that grinding wheels, dressers, and related components must work together to deliver superior performance.

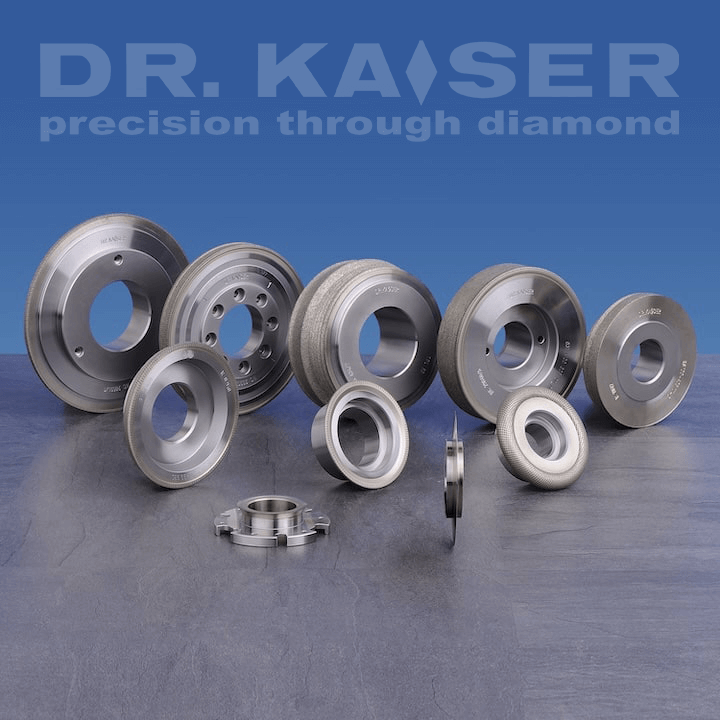

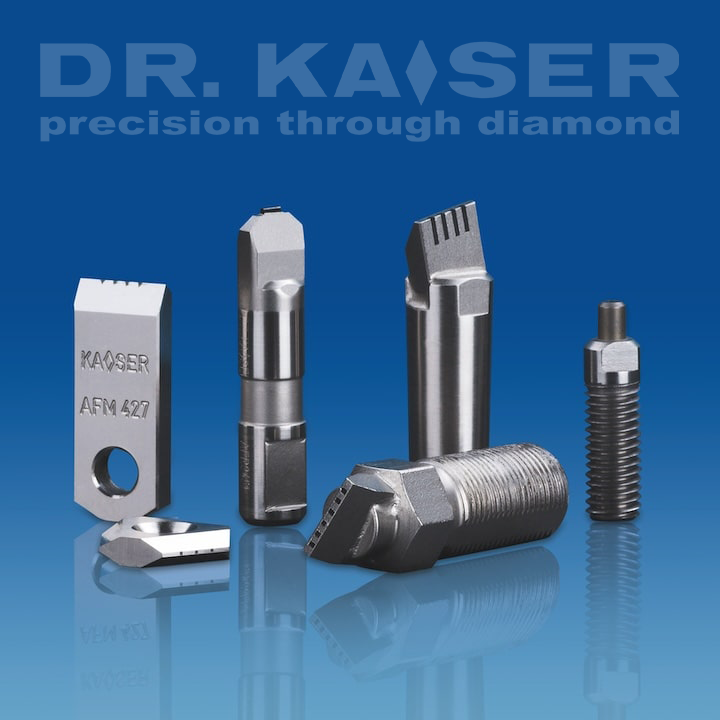

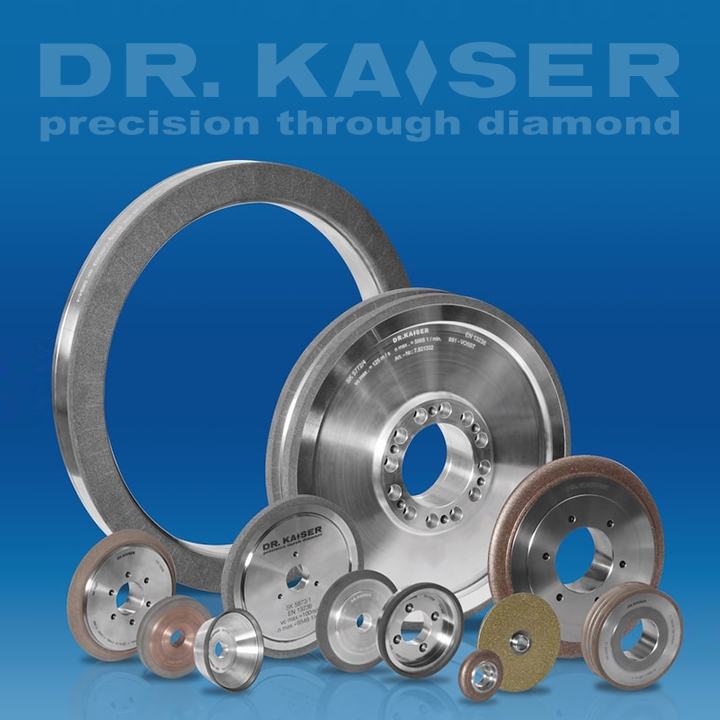

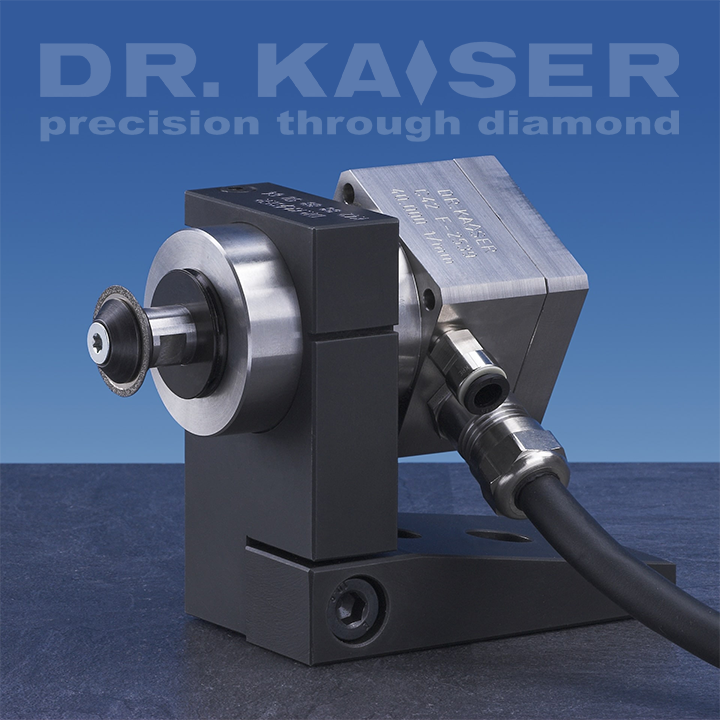

Together, CDT and DR. KAISER bring complementary strengths. DR. KAISER offers technologies CDT does not manufacture, including spindle systems, wear protection, and specialized types of rotary dressers. CDT manufactures custom diamond and CBN grinding wheels with larger diameters, complex configurations, and a broad range of bond types and grit sizes. The result is a more integrated solution for advanced manufacturers, including:

Grinding wheels and rotary dressers engineered to your process

Expanded options in grinding, dressing, spindle, and wear-protection technologies

Application support focused on data-driven results

What Changes in North America

As of February 11, 2026, DR. KAISER has transitioned North American product sales to Continental Diamond Tool. CDT now represents DR. KAISER’s full product portfolio across the United States, Canada, and Mexico, supported by CDT’s established network of sales representatives and application engineers.

For customers, this means DR. KAISER’s German-manufactured technology is paired with CDT’s process knowledge, fast communication, and local technical support. CDT sales engineers work closely with customers to align grinding performance goals, dressing strategies, and overall process outcomes when specifying DR. KAISER solutions.

“We look forward to welcoming DR. KAISER customers to CDT,” said Shane Vardaman, Chief Commercial Officer at Continental Diamond Tool. “Our focus is on operational continuity, responsive technical support, and ensuring customers experience a seamless transition in service.”

Expanded Capabilities in Central Europe and Turkey

Through the partnership, DR. KAISER will offer CDT’s diamond and CBN grinding wheels throughout Central Europe and Türkiye. This expands access to CDT’s plated and hybrid bond grinding wheels with large diameters as well as our vitrified bond double disk grinding wheels.

Together, the companies provide a shared platform to better support manufacturers working with demanding materials and tight tolerances.

“This partnership expands how we can serve customers,” said Christoph Müller, Head of Sales at DR. KAISER. “Working with CDT allows us to combine complementary strengths and offer more extensive grinding solutions on a global scale.”

Growing Through Shared Values and Vision

This alliance offers customers a true system-provider model—combining proven technology with expert service. Both organizations bring decades of experience and a common commitment to:

Precision and quality

Custom innovation

A systems-based approach

Responsive technical support

“This is more than a distribution change—it’s a long-term partnership built around how advanced grinding is evolving,” said Nick Viggiano, President at Continental Diamond Tool. “Together with DR. KAISER, we’re focused on delivering integrated solutions that help manufacturers meet increasingly complex requirements in manufacturing.”

For more information about DR. KAISER products in North America or CDT’s global capabilities, visit CDTUSA.net or DRKAISER.de. Contact your sales representative to get started.

Continental Diamond Tool designs, develops, and distributes custom grinding and dressing technology for advanced manufacturing worldwide. Founded in 1973, CDT supports precision manufacturing across industries such as aerospace, automotive, cutting tools, medical, and energy. The company operates manufacturing facilities in the United States and the United Kingdom and is known for innovation in superabrasive solutions and expert application support.

DR. KAISER DIAMANTWERKZEUGE GmbH & Co. KG built its reputation as a leader in diamond rotary dressers before expanding into grinding wheels, spindle systems, stationary dressing, and wear-resistant components. Founded in 1977 and headquartered in Germany, the company supports high-performance grinding applications worldwide and is recognized as a system provider, delivering innovation and expertise across dressing, grinding, spindle, and application technologies, including the DR. KAISER dressing and grinding app.

How Vitrified CBN Wheels Improve OD and ID Grinding

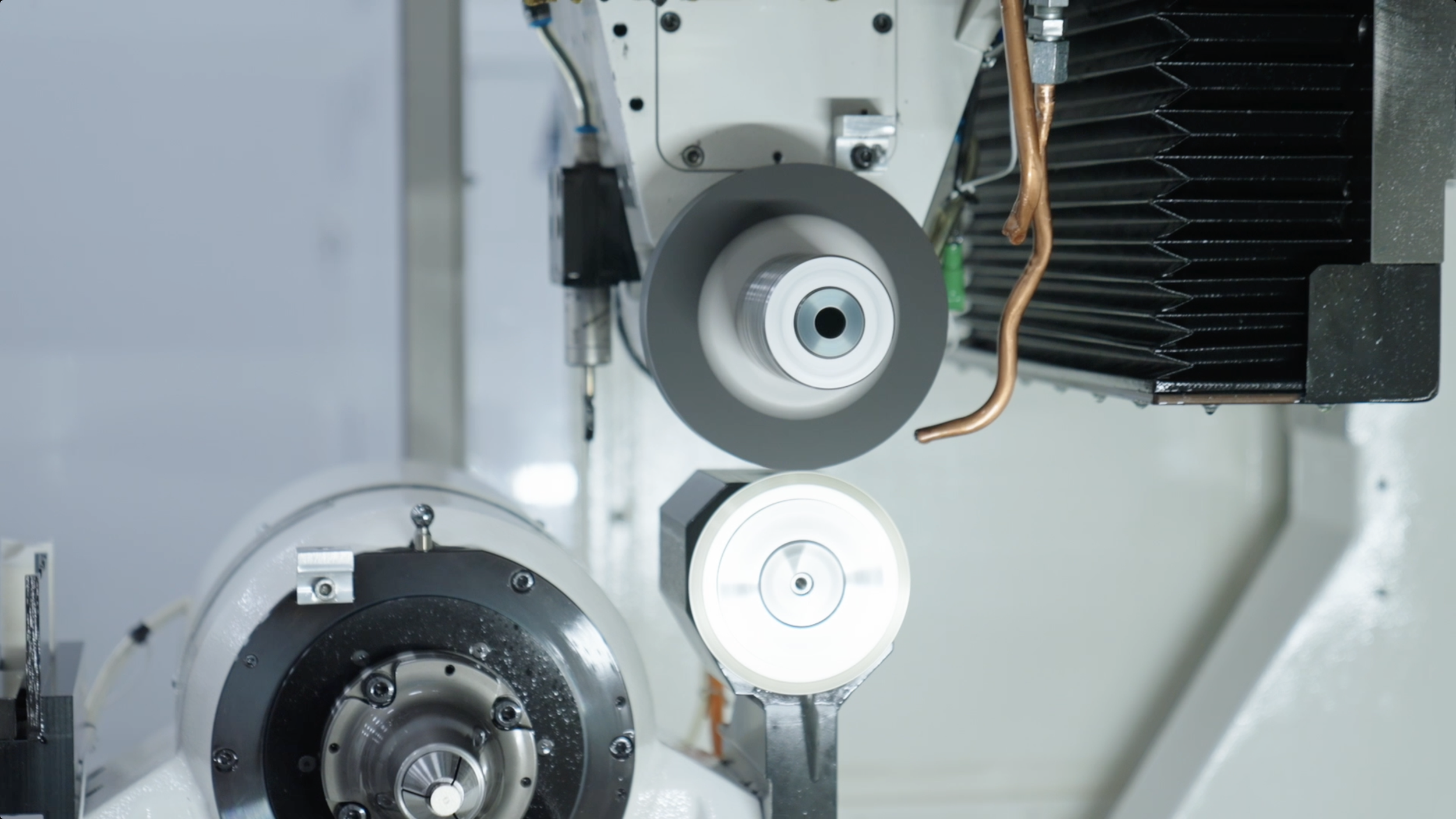

CDT demos vitrified CBN wheels on the STUDER S131R, showing their form stability and thermal control in OD and ID grinding.

In high-precision ID and OD grinding, maintaining consistency over long production cycles can be challenging. Grinding forces naturally wear the wheel over time, so holding parts in tolerance becomes a matter of how long the wheel can hold out before it needs maintenance. As shops move toward automated or minimally attended operation, wheel form retention and thermal control become limiting factors in how long a grinding operation can reliably run.

In the video below, CDT Application Engineer Andrew Olvera discusses how Continental Diamond Tool’s vitrified CBN wheels perform on the STUDER S131R in both OD and ID grinding applications. Watch the video below for a quick overview, or read on to learn why vitrified CBN wheels are often selected for production environments where long-term consistency matters.

Vitrified CBN Wheels on the Studer S131R Support Longer, More Consistent Production Runs

The STUDER S131R is widely used for high-precision internal and external cylindrical grinding in many manufacturing setups. In production environments aiming to extend run times or reduce operator intervention, the grinding wheel plays a major role in producing reliable parts.

In a demonstration at United Grinding North America, Andrew Olvera discussed the benefits CDT’s vitrified CBN wheels bring to both OD and ID grinding on the STUDER S131R. Compared to conventional grinding wheels, vitrified CBN wheels offer performance characteristics that help support stable grinding over longer production cycles.

“People prefer our vitrified CBN wheels over conventional wheels because they outperform, hold their form longer, and cut cooler,” Andrew explains. “These characteristics make them well suited for lights-out production.”

The Effects of Form Retention on Uptime and Total Process Value

As production runs get longer, maintaining part geometry increasingly comes down to the grinding wheel. CDT’s vitrified CBN wheels can offer significantly longer wheel life—up to 100 times that of conventional abrasives in some applications.

Because they hold their form longer, dressing frequency and the associated machine downtime is reduced. While vitrified CBN wheels carry a higher upfront cost, extended wheel life and fewer interruptions often offset that investment by improving uptime and reducing process variability.

For OD and ID grinding on machines like the STUDER S131R, improved form retention leads to more predictable results and longer, uninterrupted runs—key factors for shops working toward automated or unattended operation.

Vitrified CBN: Why Cooler Cutting Prevails

Thermal control is another critical factor in precision grinding. Excess heat in the grinding zone can lead to burn, surface damage, or dimensional fluctuation, particularly during continuous or high-duty-cycle production.

The open, rigid structure of CDT’s vitrified bond promotes efficient chip clearance and controlled grain exposure. This allows the wheel to cut freely while managing heat more effectively. Cooler cutting helps protect surface finish and part integrity over longer runs.

Reducing Operator Intervention for Automated Setups

Historically, grinding wheels have been one of the highest-maintenance elements in the grinding system. As wheels wear, changes in cutting behavior, form loss, and thermal load often require frequent dressing and operator adjustments, interrupting production. For shops pursuing automation, this directly limits unattended runtime.

Vitrified CBN wheels help reduce dressing intervals by delivering:

Wear-resistant abrasive grains

Long-lasting form stability

Improved thermal control

These attributes make vitrified CBN wheels a strong fit for production environments where machines are expected to run predictably with minimal oversight.

How Vitrified CBN Addresses the Unique Challenges of OD and ID Grinding

OD and ID grinding present different production challenges. ID grinding is especially sensitive to thermal buildup and wheel wear due to smaller wheel diameters and restricted coolant access. OD grinding, on the other hand, involves longer contact lengths and higher cumulative material removal, placing greater demand for a wear resistant wheel wheel.

In both cases, CDT’s vitrified CBN wheels provide cooler cutting behavior and strong form retention, helping reduce process variation over extended runs. Improved wear resistance supports more consistent results across longer production cycles on machines like the STUDER S131R.

When Vitrified CBN Makes Sense

Vitrified CBN wheels carry a higher upfront cost than conventional abrasives. For some production environments, that investment may be offset by longer wheel life, reduced dressing, and improved uptime. As part counts increase and production cycles get longer, fewer process interruptions and lower tooling replacement costs can reduce the overall cost per part.

When that break-even point is reached depends on factors such as material, removal rates, tolerance requirements, and expected runtime. Evaluating these variables helps determine when vitrified CBN makes economic sense.

If you’re running a STUDER S131R—or another high-precision grinding platform—and looking to improve consistency in automated or extended-run production, CDT’s technical sales team can help you evaluate vitrified CBN wheel options for your process with a complimentary quote.

Contact Continental Diamond Tool to discuss your material and machine setup, and learn how vitrified CBN grinding wheels can support your production goals.

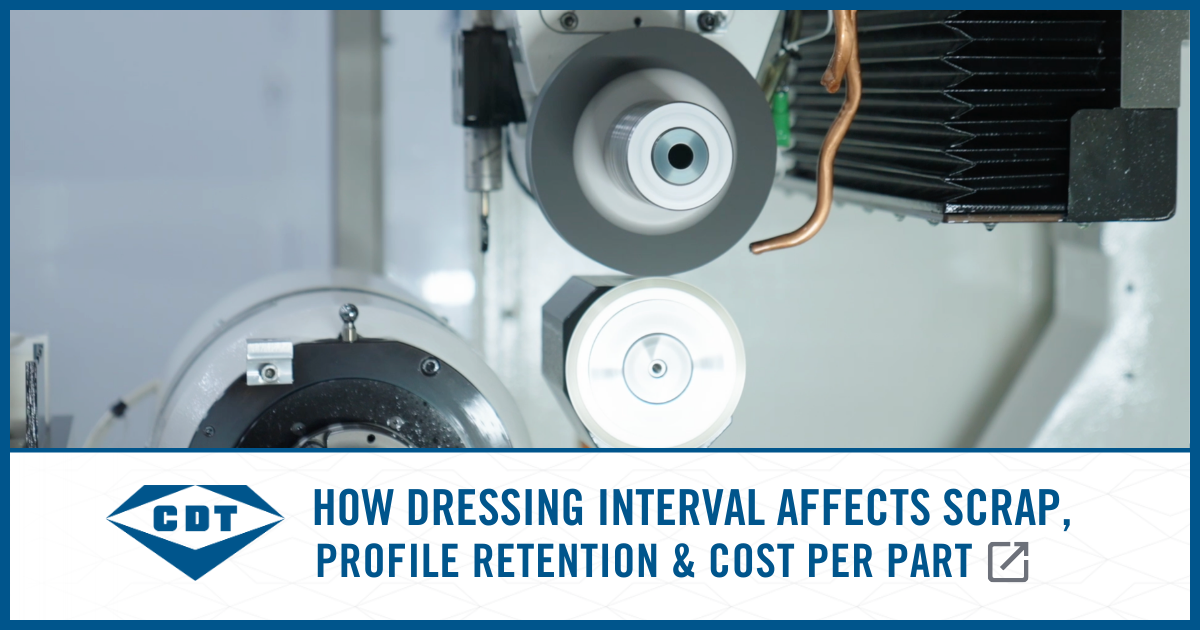

How Dressing Interval Affects Profile Retention, Scrap, and Cost per Part

Learn how dressing interval affects grinding wheel performance, profile retention, scrap rates, and cost per part in precision grinding operations.

Most grinding issues do not appear suddenly. Instead, the condition of the grinding wheel gradually breaks down during the production run until parts fall out of spec. Regular dressing and truing help keep wheel wear in check.

At Continental Diamond Tool (CDT), we approach the dressing interval as an important variable that directly influences performance. From our facility in Wales, we design and manufacture high-precision reverse-plated rotary diamond dressers tailored to specific grinding applications. CDT sales and application engineers are available to provide operating guidance on dressing frequency to balance tool life, part quality, and process stability.

What Happens During Grinding and Dressing

Grinding

As grinding wheels wear, several mechanisms work against consistent grinding performance:

Dulling of abrasive grains, which reduces cutting efficiency

Material loading, which interferes with chip formation

Glazing, which increases heat generation

Left unchecked, these effects reduce cutting performance and contribute to loss of profile accuracy and dimensional control.

Dressing and Truing

The process of dressing and truing restores wheel geometry, exposes fresh cutting edges, and establishes the surface condition required for stable material removal.

An optimized dressing interval helps maintain:

Consistent wheel sharpness

Stable grinding forces

Predictable thermal behavior

Reliable dimensional control

Because wheel condition changes continuously during grinding, dressing must be applied at a defined interval to maintain consistent performance. How often dressing and truing are applied determines whether wheel wear remains controlled or turns into scrap, rework, and downtime.

The Consequences of Late-Run Scrap

In a perfect world, the grinding wheel would maintain its condition for the full production run. In reality, wheel wear progresses independently of any planned production cycle. Changes are often subtle at first, making it difficult to identify exactly when part quality has drifted out of spec.

As wheel condition deteriorates, shifts in cutting behavior, heat generation, and material removal can go unnoticed. By the time late-run scrap is identified, multiple components may already be affected. Earlier parts may need inspected again to determine when the process first deviated, adding unplanned downtime.

Late-run scrap is particularly disruptive because it combines material loss with lost time for investigation, reinspection, and stabilizing production. Maintaining consistent wheel condition through regular dressing helps limit process variability, reduce late-run scrap, and minimize the investigation and recovery effort that often accompanies end-of-run failures.

Are You Dressing Too Often—or Not Often Enough?

While dressing and truing are essential to many grinding processes, it is possible to have too much or too little of a good thing.

Over-Dressing

It may be tempting to dress more frequently to head off quality issues before they can develop. However, over-dressing accelerates wear on both the grinding wheel and the diamond dresser. Each dressing cycle removes usable abrasive material and incrementally wears the diamond roll.

When dressing intervals are too short, this can result in:

Accelerated wear of the grinding wheel and diamond dresser

Increased downtime for wheel and roll changes

Higher tooling and maintenance costs

Frequent interruptions for dressing reduce productive grinding time, negatively impacting throughput and cost.

Under-Dressing

At the other extreme, trying to maximize overall productivity by delaying dressing until problems arise introduces a different set of issues. Under-dressing allows wheel wear, loading, and glazing to accumulate.

As the wheel loses cutting efficiency and geometric accuracy, the process becomes unstable. Common consequences include:

Unacceptable surface finish

Thermal damage or burn

Chatter and vibration

Dimensional variation out of tolerance

Not only does this create scrap, it also prolongs downtime. In many cases, multiple dressing cycles are required to restore the grinding wheel’s geometry. Extended dressing time accelerates diamond roll wear and delays the return to stable production.

The optimal dressing interval lies between these extremes and must balance wheel sharpness, profile accuracy, and tool life.

Is There a “Recommended” Dressing Interval?

This is one of the most misunderstood questions in dressing.

There is no universal dressing interval that works equally well for every grinding process. Dressing performance depends on a complex interaction of variables, including:

Grinding wheel specification, including abrasive type, bond, and structure

Workpiece material and hardness

Stock removal rates

Wheel speed and feed parameters

Dressing method and dressing ratios

Required surface finish and profile tolerances

At CDT, we produce dressers for multiple dressing methods, each with its own ratios and parameters to condition the grinding wheel correctly for the application. A dressing interval that performs well for one material or geometry may produce burn, chatter, or profile loss in another.

For this reason, dressing should be treated as an engineered process decision rather than a fixed rule. Optimizing dressing frequency is best achieved by evaluating the entire grinding system and making adjustments based on actual process behavior.

Dressing as a Lever for Cost per Part

When dressing intervals are optimized, the benefits extend beyond part quality. A stable dressing strategy contributes to:

Longer grinding wheel life

Extended diamond dresser life

Reduced unplanned downtime

Lower scrap rates

More predictable production schedules

All of these factors directly influence cost per part. In high-value grinding applications, even modest improvements in tool life or scrap reduction can yield meaningful cost savings over the life of a program.

Conversely, poorly optimized dressing intervals may be explained away as wheel problems or undiagnosed process variability when the underlying issue lies in how often the wheel is being dressed.

Partnering on the Right Dressing Strategy

Because dressing behavior is highly application-specific, the most effective solutions are developed through collaboration. Optimizing dressing frequency requires evaluating the entire grinding system and adjusting based on real process behavior rather than generic recommendations.

CDT maintains a team of experienced sales and application engineers who can support customers, when needed, in collecting and analyzing process data to identify the optimal dressing interval for their application. If a grinding process shows signs of instability, late-run scrap, or excessive tool wear, the dressing interval is often one of the most impactful process variables to review for improving overall performance.

Continental Diamond Tool Limited (CDT Ltd.), based in Kinmel Bay in Wales, is the European subsidiary of Continental Diamond Tool Corporation, headquartered in New Haven, Indiana, U.S.A. For more than 40 years, CDT Ltd. has been a leader in diamond rotary dresser technology, originally operating as Consort Precision Diamond. Since joining CDT, the company has expanded its product line, delivering high-performance diamond plated grinding wheels and other premium superabrasive products to customers worldwide.

CDT Opens 2026 Ready for Growth

CDT President Nick Viggiano reflects on 2025 investments and shares how Continental Diamond Tool is positioned to support customers in 2026.

As we begin 2026, Continental Diamond Tool enters the new year with momentum, readiness, and a clear focus on partnership. The past year was one of meaningful investment. We’ve been deliberate in our growth to ensure our customers remain supported as the global manufacturing landscape becomes more complex.

In this video message and article below, CDT President Nick Viggiano reflects on the milestones achieved in 2025 and outlines how those efforts have positioned CDT—and our partners—for continued success in the year ahead.

Watch the video or read the article below to see the President’s Message: Welcoming 2026

Supporting Our Partners Today and Tomorrow

Since 1973, Continental Diamond Tool has grown alongside the customers and industries we serve. Entering the superabrasives industry early in its commercial development, our growth has always been driven by relationships: listening closely and responding quickly with innovative solutions that perform in real production environments.

In 2025, this approach guided some of the most significant investments in CDT’s history. Against a backdrop of shifting tariffs, geopolitical unrest, and increasing supply chain uncertainty, we have taken deliberate steps to ensure our customers can rely on us without interruption.

2025: Strengthening Capacity and Capability

Throughout 2025, CDT focused on expanding our ability to serve customers in North America and Europe with speed, consistency, and confidence.

Facility Expansion in the United States

We completed the fit-up and moved into our 72,000-square-foot expansion in New Haven, Indiana, increasing our total footprint to 200,000 square feet. Speaking to the expansion, Nick explains, “This couldn’t come at a better time as we are seeing the reshoring of manufacturing here in the U.S., which has put us in a great position to handle new and existing customer growth in North America.”

New Facility in Wales

In Q3 of 2025, our team in Wales transitioned into a larger, newly renovated facility. The team has adapted quickly, supporting new customer growth across Europe while expanding our global manufacturing and application support capabilities.

Supply Chain Resilience

To protect our customers from global uncertainty, CDT has made several proactive investments. In the video, Nick explains, “With the uncertainty of tariffs and government posturing between countries around the world, we decided to put an 18-month supply of diamond in our vault to ensure that we will be able to deliver no matter the global climate.”

Continued Investment in People

Emphasizing what differentiates CDT, Nick adds, “What continues to set us apart is our customer service and application team that supports our sales team. While our competition continues to eliminate these positions, we continue to add these valuable members.” CDT remains committed to investing in these roles to help customers optimize processes, innovate solutions, and fully realize the value of our products.

What We Reinforced Along the Way

The lessons from 2025 reaffirmed what has long set CDT apart:

Service Matters – Strong application and customer support remain central to helping customers fully realize the value of our products.

Preparation Enables Confidence – Investing ahead of demand allows us to support growth without compromise, even in the face of uncertainty.

Partnership Drives Progress – The best solutions are built through collaboration, when customers and suppliers throughout the value chain work together toward a shared goal.

2026: Moving Ahead with Clarity and Focus

As we head into 2026, CDT is excited about new partnerships that will further expand our ability to support advanced grinding applications. These collaborations are being developed with a clear goal in mind: helping our customers succeed as requirements become more complex and expectations continue to rise.

Quality, service, and partnership remain central to how we approach our work and our relationships. These principles help guide our decisions and shape where we invest.

Closing his message, Nick expressed his appreciation: “To our customers around the world, thank you for choosing CDT as your trusted partner. Your confidence in our team inspires us to continue adapting and growing to deliver solutions that support your success. You are the reason we exist.”

Stay Connected with CDT

Discover CDT’s latest product developments, company news, and educational resources through our blog, videos, and LinkedIn presence. We’re committed to supporting the grinding community with solutions that move precision manufacturing forward.

What Community Investment Has to Do With Manufacturing Success

See how Continental Diamond Tool supports community and workforce partnerships that strengthen reliability, service, and long-term customer success.

At Continental Diamond Tool, partnership is central to how we operate—whether that’s with our customers, our industry, or the community around us. We approach each relationship with the same expectations: mutual trust, shared commitment, and a long-term mindset. Those values guide how we do business every day, and they also guide how we give back.

As we close out 2025, we’re reflecting on where CDT has invested in local organizations, youth programs, and workforce development. These investments matter to our community and also support our long-term success as a company. A strong community makes us a better company, by supporting how we provide quality products, expert services, and responsive support to our customers.

Community Partnerships for a Stronger Team

Supporting the community starts with supporting its people and investing in programs that develop talent, skills, and leaders to help build a stronger workforce for the future.

That starts close to home, with our employees’ families and local youth. In 2025, CDT continued to support a variety of youth organizations, including dance programs, baseball and softball leagues, and youth camps. We also supported East Allen County Schools (EACS) and Central Lutheran School through team-based activities such as athletics, band, and choir.

In addition, CDT donated to the installation of American flags in school gymnasiums as a way to recognize our shared values, community pride, and the success of American-made innovation.

These programs give young people opportunities to learn responsibility, teamwork, and accountability. Over time, those same qualities add value in the workplace. For our customers and partners, it means working with those that take pride in their work and fulfill commitments.

Strong Communities Support Reliable Service

CDT’s involvement in community safety and local events reflects a simple belief: strong communities help create stable, reliable businesses.

Throughout the year, CDT sponsored seasonal programs and parades for the City of New Haven designed to bring citizens together. We also continued our support of the New Haven Police Department and the New Haven Adams Township Fire and EMS Department, recognizing the important role they play in keeping our community safe.

A company rooted in a safe and healthy community is better able to recruit and retain experienced employees, keep operations running smoothly, and respond when customers need it. That stability matters to our team and customers.

Workforce and Business Development With Customers in Mind

CDT’s involvement in workforce and business development is closely tied to customer success. Through our involvement with Greater Fort Wayne, Inc., the New Haven Chamber of Commerce, and the Indiana Chamber of Commerce, we work alongside regional partners to support economic growth and talent development.

Through our work with the Grow Allen Initiative, which supports career pathways for students after high school, and the engineering department at Trine University, students are gaining exposure to real-world opportunities in advanced manufacturing. It has been rewarding to show students what high-tech jobs are available to them right here at home.

In addition, CDT offers positions for high school and college students during summer months and school breaks. These roles give students hands-on exposure to manufacturing environments and potential career paths, helping them make more informed decisions about their future.

Our annual sponsorship of Big Brothers Big Sisters (BBBS) and support of Junior Achievement also represent our commitment to encouraging mentorship, leadership, financial literacy, and workforce readiness across our community.

Together, these efforts help ensure CDT has the people, skills, and capacity needed to remain a reliable partner to customers over the long term.

Community Commitment Without Compromise

Our commitment to the community strengthens our commitment to our customers. The same principles that drive strong partnerships and service to our customers also fuels our involvement in the community: show up, do what we say we’ll do, and invest in growth for long-term impact.

We remain fully focused on delivering custom grinding solutions, responsive service, and technical support. At the same time, we know that being a dependable partner means investing in the people and communities that make our work possible.

As we look ahead, CDT remains committed to growing alongside our customers, strengthening partnerships at every level, and continuing to support the communities that support us.

From all of us at Continental Diamond Tool, thank you to our customers, employees, industry, and community partners who have grown alongside us. We look forward to continuing these partnerships and wish everyone nothing but success in 2026.

Why This Grinding Demo Caught Toolmakers’ Attention

CDT tests EVO Hybrid Bond on the Walter Mini Plus—see what the results reveal about performance in carbide tool production.

In cutting tool manufacturing, productivity gains often hinge on one critical factor: wheel performance. CDT’s EVO™ Hybrid Bond grinding wheels offer distinct advantages in demanding carbide grinding applications, but the real story is how they behave in high-accuracy tool development work. To see how these wheels perform on United Grinding’s Walter Helitronic Mini Plus, watch the video demonstration below, or read on for a deeper look at what makes this hybrid bond technology such a powerful solution for tool manufacturers.

Watch the video or read the article below to see why this grinding demo caught toolmakers’ attention.

Hybrid Bond Performance on the Walter Helitronic Mini Plus

Shops faced with growing demands for speed and precision rely on grinding tools that can keep up, and that’s been the focus of CDT’s new product development with our EVO Hybrid Bond line. Harrison Sheldon, R&D Application Engineer at CDT, recently demonstrated this next-gen bond technology on the Walter Helitronic Mini Plus, showcasing the wheel’s capability in flute and tool grinding.

“We’re pretty excited about the new offerings from CDT, including our high-performance flute grinding and tool grinding products,” Harrison says. “We have our new EVO products on the machine demonstrating their great grinding abilities.”

For operations where stability, burn control, and form accuracy directly impact tool quality and cycle time, these EVO diamond wheels are a game changer. The demonstration highlighted several benefits a custom hybrid bond wheel can bring to cutting tool production.

Why Hybrid Bond Wheels Excel in Tool Grinding

EVO Hybrid Bond diamond grinding wheels combine the best characteristics of resin and metal bonds to create a wheel that is both fast-cutting and dimensionally stable. This makes them particularly well suited for flute grinding, secondary relief grinding, periphery, and other geometries where accuracy and wheel wear must stay tightly controlled.

1. Aggressive yet Controlled Cutting Action

EVO’s specially formulated bond allows superabrasive grains to cut freely while maintaining structural support. This balance delivers:

Higher feed rates

Lower grinding forces

Reduced cycle times

This is especially valuable in operations where standard resin bonds would wear too quickly or require frequent dressing.

2. Improved Thermal Performance

Tool steels, carbide blanks, and increasingly complex tool geometries place significant heat load into the grinding zone. The EVO wheel system with its copper core is built to dissipate heat efficiently, helping reduce:

Risk of burning

Micro-cracking

Thermal distortion

“These wheels really show strong, stable performance even at more aggressive speeds and feeds,” Harrison notes. “That’s a big advantage for customers trying to push productivity while keeping their tools cool and consistent.”

3. Extended Tool Life and Fewer Changeovers

Hybrid Bond diamond wheels maintain form longer than standard resin-bond wheels. This translates into:

Longer dressing intervals

Less wheel wear

More consistent part geometry

Whether this wheel is running in tool shops with high-mix, low-volume production or operations grinding carbide round tools around the clock, these improvements mean increased uptime and reduced consumable cost.

4. Ideal for High-Precision Machines

The Walter Helitronic Mini Plus is built for accuracy, and the performance of CDT’s Hybrid Bond diamond grinding wheels complements its capabilities. The wheel’s stability ensures that both form accuracy and flute consistency remain controlled throughout long runs or high-removal-rate passes.

best Applications for Hybrid Bond diamond grinding wheels

EVO Hybrid Bond diamond grinding wheels are a strong fit for a range of carbide and HSS tool manufacturing applications, including:

Flute grinding

Primary and secondary relief grinding

Step tool grinding

Chamfering and point thinning

End mill and drill production

Their ability to maintain shape while cutting aggressively makes them particularly effective in flute grinding where high-precision is essential for ultimate tool performance.

In addition to round tools, CDT also offers EVO Hybrid Bond periphery diamond wheels for carbide insert grinding, where consistent form retention and thermal stability are especially critical.

Top-of-the-line Diamond Grinding Wheels for All Major Tool Grinders

This demonstration was filmed at United Grinding’s Precision Summit last summer, where CDT showcased how its wheels perform on industry-leading equipment. CDT customizes grinding wheel solutions for all major machine OEMs—including United Grinding—to ensure customers get reliable, real-world performance across their production environments.

“We appreciate having the opportunity to test these wheels on the Walter Mini Plus. The results really show what this technology can do for tool manufacturers,” Harrison says. “It’s exciting to bring new products like EVO to the market with this level of performance.”

How to Get Hybrid Bond Grinding Wheels for Your Walter Mini Plus

If you work in cutting tool manufacturing and would like to explore EVO Hybrid Bond diamond grinding wheels for your flute grinding, relief grinding, or insert production process, reach out to our sales team or request a quote at cdtusa.net/hybrid-bond.

If you operate in another industry and need a specialized grinding solution, CDT’s product engineering team can work with you to develop a custom hybrid bond formulation tailored to your material, machine platform, and performance goals. Contact us to get the conversation started.

What a 20-Year-Old Apprentice Reveals About New Jobs Coming to North Wales

CDT's growth brings new job opportunities for apprentices and skilled operators at its larger advanced manufacturing facility in North Wales.

Continental Diamond Tool is entering an exciting phase of growth. Over the next two years, we’ll be adding up to 30 new jobs in North Wales to meet the needs of growing industries in Europe and around the world.

Twenty-year-old apprentice Stephanie Hughes-Jones is one of the standout new hires whose experience highlights the opportunities opening up in Kinmel Bay.

At this location, we design and manufacture custom diamond rotary dressers and ultra-high-precision plated grinding wheels for aerospace, automotive, and other advanced industries. The need for superabrasive solutions is growing as more manufacturers turn to hard-to-machine materials like ceramics, hardened steels, and composites.

At CDT, we hear what our customers need, and we respond. The launch of our electro-plated production line in North Wales in 2023 has been a major success. This line, which produces both diamond and CBN grinding wheels, is expected to become the site’s largest product category in the near future.

Our sales team is also bringing CDT’s superabrasive products to new international markets. We now have dedicated local representatives in the Middle East, Mexico, and Poland.

Of course, growth requires investment. That’s why we’ve spent £4 million to upgrade our Kinmel Bay operation. Last summer, the team moved into a purpose-built 30,000 sq ft facility on the Tir Llwyd Industrial Estate — three times the size of our previous site. With this expansion, we will be doubling production capacity and have already increased our team from 35 to 46 skilled workers.

Our growth plan includes expanding the team to around 80 people over the next few years. To get there, we’re actively recruiting both apprentices and skilled operators.

Stephanie — a former pupil of Prestatyn High School — joined CDT after being encouraged by her brother Dan, who also works here. Today, she operates CNC lathes and milling machines, manufacturing high-specification tooling used by customers across the world.

When asked what brought her to custom manufacturing, she said:

“My dad is a mechanic and runs his own garage, and my brother Dan got into engineering. He went to Llandrillo College and joined CDT, and I’ve followed in his footsteps.

I gained my Level Three engineering qualification and did work experience here – people are really surprised when I say I’m an engineer and make things.

I love it. Your brain is constantly working things out and thinking of ways of doing things better. I’ve worked in retail before and didn’t really enjoy it, but this is great.”

While manufacturing has historically been a male-dominated field, CDT has worked to create an environment where anyone with interest and motivation can thrive. A sizable percentage of our workforce is women, and that number continues to grow. Here’s how Stephanie describes her experience:

“I think more girls should get into engineering – they’d enjoy it more than they think.

It is a bit intimidating at first, but everyone here at CDT has been very welcoming and helpful. The company has really encouraged and supported me.

I’m on Level Four HNC now, and next year I would like to move on to a degree apprenticeship.

There’s no reason women can’t do this job just as well as men – gender doesn’t make a difference here. With interest and training, anyone can do it.”

Kinmel Bay’s Production Manager Justin Hughes, who joined the company 18 years ago and whose father was part of the original management team, agrees:

“Stephanie has been an outstanding recruit. Now that we’ve completed the move to the new site, we’re resuming our apprentice programme, and I’m looking forward to seeing more young people working here soon.

The much larger building we have now has allowed us to completely remodel our processes for greater efficiency and a more comfortable working environment – in the old unit, you could hardly move.

It’s been incredible to see the transformation. The expansion is a testament to the strength of our partnership with our parent company in the USA and how committed they are to our success.

Now that we have the space, we’re investing in technology and people to take the business forward.

We’re well placed to make the most of growth in emerging markets – and it’s an exciting time to be part of what’s happening here.”

If you’re hands-on, enjoy a challenge, and eager to grow, we’d love to hear from you. Find job opportunities at our Kinmel Bay facility and the form to apply on our Careers page.

Continental Diamond Tool Limited (CDT Ltd.), based in Kinmel Bay, Rhyl, U.K., is the European subsidiary of Continental Diamond Tool Corporation, headquartered in New Haven, Indiana, U.S.A. For more than 40 years, CDT Ltd. has been a leader in diamond rotary dresser technology, originally operating as Consort Precision Diamond. Since joining CDT, the company has expanded its product line, delivering high-performance diamond plated grinding wheels and other premium superabrasive products to customers worldwide.

Engineering for Tomorrow, Today

Hear from engineers about what it's like to work at CDT — the challenges, growth opportunities, and mentorship available—as we build the best engineering team in the grinding industry.

Continental Diamond Tool (CDT) is a custom engineering firm that designs, develops, and manufactures superabrasive grinding wheels and dressing tools for global precision manufacturing. From aerospace and automotive to energy and medical technology, CDT products are shaping advancements around the world. And behind every tool is a team of engineers — from product engineers and process engineers to R&D and application specialists — driven to meet the evolving needs of customers who are continuously pushing what’s possible in manufacturing.

Watch the video or read the article below to see how CDT is building an engineering team for tomorrow, today.

Adapting for the Future

At CDT, every project begins with a customer challenge. When our customers develop technology using increasingly advanced materials and more sophisticated equipment, we adapt by designing the tools that make their success achievable. It’s an environment where problem-solving, creativity, and technical expertise come together to turn complex engineering challenges into real-world solutions.

Growing Through Experience

At CDT, our future focus starts with people. We’re building an engineering team that can adapt, lead, and solve for what’s next in manufacturing. For new product engineers like Daniel Montez, joining CDT has meant joining a team that knows collaboration sparks innovation.

“The knowledge here is unmatched,” says Daniel. “You have people from all different backgrounds coming together in one place — collectively decades worth of experience coming together to make the best product that they can.”

That diversity of knowledge defines CDT’s culture. It’s a place where mentorship, career growth, and continuous learning are built into the workflow. Here, every engineer plays a role in advancing precision manufacturing.

“At CDT, we’re passionate about building the best technical team in the industry — a team defined by excellence in quality and service,” says Jack Shindle, VP of Engineering, Research, and Development. “We’ve created an environment where knowledge sharing happens naturally, and where every engineer has the opportunity to grow and make an impact.”

For Daniel, that support system is what makes CDT stand out.

“I’m always talking to the head engineer in my department,” he explains. “He sits right across from me in the office and is always ready to show me something new, give me a challenge, or walk me through something. That kind of support is what so many engineers need.”

The result is a workplace where engineers are encouraged to think differently, share ideas, and grow through hands-on experience. Every new project brings opportunities to learn, whether it’s optimizing a wheel for a new grinding process, experimenting with a new dressing method, or supporting a customer’s move into next-generation materials.

Scaling Leadership

At CDT, growth isn’t limited to technology: it extends to our people. Service is at the heart of everything we do, and delivering the best results for our customers requires a team with the awareness, communication, and leadership skills to anticipate needs and respond with confidence. In 2024, we launched a leadership development program and restructured our teams to better align expertise with customer goals. This shift has brought clearer roles, faster collaboration, and a shared philosophy of proactive partnership across the organization.

“The availability for growth at Continental Diamond Tool is outstanding,” says Zeb Domer, VP of Bonded Products, who began his CDT journey as a process engineer. “We’re committed to growth and service, and that extends to our people. We make sure our engineers have the tools, training, and leadership support they need to advance their careers right here.”

At CDT, professional development is encouraged, recognized, and celebrated. For Daniel, that support has transformed his early career into a journey of hands-on learning, high-tech engineering design, and leadership development.

“The most exciting thing about being here at CDT is all the experience I’m gaining— learning how to be an engineer, how to design, how to work with people, and soon enough, how to be a leader.”

At Continental Diamond Tool, customer challenges drive our adaptation, and it’s the engineers and technical specialists of today who are shaping the tools that make tomorrow possible.

Join the Team

If you’re a product engineer, process engineer, or problem solver who’s ready to shape the future of manufacturing, there’s a place for you at CDT. Here, you’ll gain experience with advanced materials, cutting-edge processes, and the mentorship to keep growing throughout your career. We believe in developing talent from within and giving every team member the chance to get creative and make an impact.

Check out our Careers page to see available opportunities. Or if you don’t see a current opening that fits your background, we still want to hear from you. CDT is always looking to connect with exceptional individuals who are passionate about precision engineering and quality craftsmanship. Submit a general application for our facilities in New Haven, Indiana, or Kinmel Bay, Wales, to start the conversation.

Faster, Cooler, and More Efficient Surface Grinding with Blue Moon TZ

CDT and Krebs & Riedel test Blue Moon TZ grinding wheels on the BLOHM PLANOMAT, proving performance in surface grinding operations.

With higher removal rates and cooler grinding performance, Blue Moon TZ has proven to be highly effective in applications that require larger contact zones like surface grinding. To see how this technology performs on the Blohm Planomat surface grinder, watch this video or read the following article.

Blue Moon TZ Grinding Wheel Performance on the BLOHM PLANOMAT Surface Grinder

At Continental Diamond Tool, we’re always looking for ways to help customers push productivity forward without sacrificing quality. That’s exactly what the Blue Moon TZ grinding wheel achieves on the BLOHM PLANOMAT surface grinder. Developed by Krebs & Riedel and offered to manufacturers in North America through CDT, this custom-engineered abrasive features precision-shaped trapezoidal grains that enhance performance in fine-finish applications like surface grinding.

“The Blue Moon TZ enables customers to grind materials much faster,” says Erik Van Meter, Product Manager at CDT. “It enables them to increase their parts per dress, and it enables them to grind with less heat, which obviously is much better for the customer.”

Unique Considerations in Surface Grinding

Surface grinding is used predominantly in the manufacture of tools and molds, where surfaces are machined plane parallel to the circumference or face of the wheel. The growing diversity of materials in these applications demands effective, innovative, and economical grinding solutions.

Surface grinding also presents a unique set of challenges: large contact zones, extended linear passes, and high thermal loads can all impact surface finish and dimensional accuracy. These conditions demand an abrasive that maintains stability and temperature control under stress.

The properties of Blue Moon TZ make it well equipped to meet these challenges. Its microcrystalline, trapezoidal rod-shaped grain delivers high cutting performance while maintaining a very low thermal load in the contact zone. This helps reduce the risk of workpiece burn or distortion, even under demanding grinding parameters.

The Role of Vitrified Bonds in Precision Grinding

Vitrified bond systems have largely prevailed in precision grinding because of their controllable porosity and adaptable microstructure. The bond type allows for customized pore space, ensuring the grinding wheel’s performance aligns with the size of the contact zone between the workpiece and wheel. Larger contact zones, such as those found in surface or creep-feed grinding, benefit from a more open and porous structure. This design helps deliver coolant directly into the contact zone and effectively remove heat and chips during grinding.

The vitrified bond structure used in Blue Moon TZ and other conventional abrasive grinding wheels contributes to its ability to maintain stability, extend tool life, and promote consistent grinding pressure. These characteristics make vitrified-bonded wheels particularly advantageous for productive surface and deep grinding applications.

Proven Results on the BLOHM PLANOMAT

To validate these performance advantages, the CDT team partnered with the experts at United Grinding to test the Blue Moon TZ wheel on the BLOHM PLANOMAT Surface Grinder. Together, they evaluated a range of process performance factors to confirm the wheel’s consistency, efficiency, and grinding stability.

The results of these tests were presented and demonstrated live at the United Grinding Precision Summit, giving attendees an up-close look at how Blue Moon TZ enhances efficiency and grinding consistency on high-performance equipment.

Performance that Speaks for Itself

When it comes to surface grinding, the Blue Moon TZ stands out for its ability to deliver both speed and control. Key benefits include:

Very low risk of overheating while grinding

High removal rates and short grinding timesSelf-sharpening abrasive grain for consistent performance

Extended dressing intervals and long tool life

Reduced cost per unit through improved efficiency

The combination of sharp-edged, self-sharpening grains and a homogeneous, controllable pore structure enables smoother coolant flow and more consistent grinding pressure. The result is improved part quality and longer wheel life.

“Customers have been very happy about CDT offering the Krebs & Riedel line,” Erik adds. “Both companies offer high-quality products, good customer service, and great technical service. There’s been a lot of good collaboration between the customers and the CDT people.”

Collaborating for Quality

The partnership between Continental Diamond Tool and Krebs & Riedel brings decades of engineering experience together to serve North American manufacturers with the latest in grinding technology. Whether that’s conventional abrasives or superabrasives, CDT ensures every customer gets a tailored solution backed by technical expertise and responsive support.

Interested in Blue Moon TZ or other abrasive solutions for your surface grinding operations?

Contact our team today to discuss your application and find the right abrasive solution.

CDT Officially Opens £4M Kinmel Bay Expansion Amid Record Sales

CDT opens a 30,000 sq ft Kinmel Bay factory in a £4M expansion—doubling capacity and accelerating electro-plated products for customers worldwide.

Continental Diamond Tool in North Wales is celebrating record sales after opening a new state-of-the-art engineering center.

Last week we officially unveiled the 30,000 sq ft plant on the Tir Llwyd Industrial Estate in Kinmel Bay, which is three times the size of the old site just half a mile away.

The move is part of a £4 million expansion plan which will see a 100 per cent increase in production capacity and a doubling of the workforce to 80 staff over the next couple of years.

There have already been benefits for the local economy because most of the contractors used for the fit-out of the new factory are based on the same industrial estate.

Demand is booming for the ultra-precise industrial tooling CDT makes in Kinmel Bay for the aerospace, automotive and oil and gas sectors, including blue chip customers like Rolls Royce, General Electric and Tenneco.

Founded in 1984 as Consort Precision Diamond, this facility's high precision diamond rotary dressing products were turbocharged after being acquired by CDT in 2018.

Nick Viggiano, Continental Diamond Tool’s President, attended the official opening along with senior executives who travelled over from the American headquarters in New Haven in Indiana.

Nick said: “This is a very proud moment to come over here and see how things have been transformed, from the factory it was before to this new space. This is wonderful.

“I think the employees feel it, and you can see in their faces they enjoy working in this new environment. I am sure we will see a great return on our investment.

“The people here are willing to try new things and push to the next level. The commitment of the team in Kinmel Bay has been a big reason behind the investment.

“We like to press forward fast and have fun doing it. I think it’s going to go really well.

“The introduction of our new electro-plated products has been a big success, and I expect they will outgrow everything else we make in this building in the next five years.”

As well as expanding the product range, CDT is breaking through into new international markets in the Middle East, Mexico and Poland where new sales teams have been established.

General manager Troy Giachero said: “One of the main reasons for our success here is the way the Welsh workforce has dovetailed with their American colleagues. Team work is everything.

“You have to invest in the people and invest in the training. We have a lot of experts on both sides of the Atlantic and the combination has enabled us to grow at the pace we have.”

He added: “One thing I’m particularly proud of is that the electric, the plumbing and the air supply for our machines was all provided by contractors on this very industrial estate.

“All the money we’ve put into this building in fitting it out was invested locally and will stay in this area, so this has helped out the local community and Wales as a whole.”

Support from the Welsh Government and Conwy County Borough Council has been key, with £100,000 from the UK Shared Prosperity Fund to help purchase new equipment.

Council Leader Cllr Charlie McCoubrey said: “It’s really impressive to see such high tech industry in Kinmel Bay, bringing really well paid jobs into this area.

“We know that SMEs are vitally important in Conwy and to see an organisation like this growing organically is fantastic with their products being exported across the world.”

It was a sentiment echoed by Cllr Nigel Smith, Conwy Council’s cabinet member for Sustainable Economy, who represents Kinmel Bay on the authority.

He said: “This investment by the American owners is most welcome. To see the transformation here today is absolutely amazing.

“There’s huge potential for growth because CDT are international market leaders. The future is very exciting for the town of Kinmel Bay, the county of Conwy and for North Wales.”

The honour of cutting the ribbon to officially open the new factory went to long-serving production manager Justin Hughes who masterminded the transfer of 100 tonnes of equipment to the new site.

He said: “We really hit the ground running when we moved here. The move from one building to the other was so smooth because we used the right people to do the job and the team went above and beyond to make it happen seamlessly.

“We’ve also had brilliant support from our American colleagues who have done this kind of thing before in the States so we really benefited from the lessons they had learned.

“We are already reaping the benefits. Our order book is the highest it has ever been and it’s only going in one direction and doing so very fast.

“We have more investment coming down the track, expanding our capability with the electro-plated lines. We now have space to keep on growing.”

Among the VIP guests were two of the original company’s founders, Steve Noakes and Peter Hughes, Justin’s father.

Sadly, one of the other founders, Dave Morris, the former managing director, passed away recently.

Mr Hughes said: “When the company was acquired, Dave was made up and he would have been absolutely over the moon to have been here today. He would have been so pleased.

“I’m also delighted to see how successful the company is and I am particularly proud of the part Justin is playing. He loves it and I am so chuffed for him.”

Related Links:

https://businessnewswales.com/north-wales-engineering-firm-unveils-new-30000-sq-ft-facility/

https://www.baysideradio.co.uk/news/expansion-sparks-record-growth-for-kinmel-bay-firm-11155

https://www.wales247.co.uk/continental-diamond-tool-unveils-4m-factory-to-meet-global-demand

https://www.welshnewsextra.com/boom-time-for-north-wales-firm-as-4m-expansion-sparks-record-sales/

Continental Diamond Tool Limited (CDT Ltd.), based in Kinmel Bay, Rhyl, U.K., is the European subsidiary of Continental Diamond Tool Corporation, headquartered in New Haven, Indiana, U.S.A. For more than 40 years, CDT Ltd. has been a leader in diamond rotary dresser technology, originally operating as Consort Precision Diamond. Since joining CDT, the company has expanded its product line, delivering high-performance diamond plated grinding wheels and other premium superabrasive products to customers worldwide.

Fixing Surface Finish with the ACT Equation

Learn how the ACT equation predicts Ra, improves surface finish, and reduces scrap in grinding. Download these equations from CDT’s website to gain insight into your process.

Surface finish is a common challenge in grinding, but the solution doesn’t have to be complicated. When Ra values drift out of spec, the result is wasted material, extra dressing, and costly downtime. In Episode 12 of The Grinding Chronicles, CDT Application Engineer Blu Conrad explained how tracking both profile and surface finish helps you identify which factor is limiting your process. Now, in Episode 13, CDT Application Engineer Harrison Sheldon takes the next step by showing how the Average Chip Thickness (ACT) equation provides a clear, data-driven way to predict surface finish and improve part quality when grinding with superabrasive wheels.

The Grinding Chronicles - Episode 13

Surface Finish Matters

A part can pass dimensional checks but still fail inspection if surface finish is out of tolerance. That’s because Ra—the measure of a surface’s micro-level peaks and valleys—directly affects performance, durability, and consistency. Left unchecked, poor surface finish leads to higher scrap rates, shorter tool life, and inefficiency on the shop floor.

To understand and control surface finish, you need more than trial and error. That’s where the ACT equation comes in.

Understanding the ACT Equation

Every time a grit on the diamond grinding wheel removes material, it leaves behind a tiny chip and a corresponding valley on the workpiece surface. Smaller chips equal smoother finishes. Average Chip Thickness (ACT) captures this relationship in a measurable way.

The ACT equation, developed by Dr. Richard Lindsay, calculates chip thickness using common grinding parameters:

In the equation’s numerator, we multiply exponents of:

grain diameter (d)

specific material removal rate (Q′)

In the equation’s denominator, we multiply exponents of:

workpiece speed (Vw)

equivalent wheel diameter (De)

wheel speed (Vs)

abrasive concentration (f)

Once ACT is calculated, two simple equations let us predict surface finish Ra:

For fine finishes (1–10 µin Ra): Ra = 6 × ACT^0.3

For finishes in the 10–100 µin range: Ra = 2.2 × ACT^0.72

These equations, based on inch values, let you estimate surface finish outcomes for cylindrical grinding with superabrasive wheels before wasting time and material. For Metric values, see our downloadable document.

download ACT & Surface Finish Equations

Sign up for our email list and get instant access to the equations (English & Metric) for Average Chip Thickness (ACT) and Surface Finish (Ra). You’ll also get CDT’s quarterly updates. Your info stays private, and you can unsubscribe anytime.

Which Parameters Matter Most?

Not all grinding parameters influence surface finish equally. The ACT equation makes that clear:

Wheel speed (Vs) carries the greatest weight because it appears in the denominator raised to a relatively large power. This means even a modest increase in wheel speed can cause a significant reduction in ACT, which directly translates to a smoother surface finish. In practical terms, wheel speed is one of the most powerful levers you have for improving Ra without overhauling your entire setup.

Workpiece rotational velocity (Vw), on the other hand, has a much smaller exponent in the equation. Adjustments here produce only minor changes to ACT, so increasing or decreasing work speed alone won’t dramatically impact your finish.

By understanding these relationships, you can focus your process adjustments where they’ll make the most difference, rather than wasting time chasing variables with little effect.

Of course, external factors still play a role. Coolant contamination, wheel runout, and machine vibration can all interfere with finish quality. But ACT provides a reliable framework to prioritize changes, isolate issues, and refine your process with confidence.

Take Control of Your Finish

Combining surface finish tracking with ACT calculations gives you the power to:

Predict Ra values with accuracy

Optimize dressing intervals

Reduce scrap and downtime

Maximize parts per dress

💡 Ready to put this into practice? Sign up to download the English and Metric equations for free and make your own data-driven adjustments.

Need additional help running the numbers or troubleshooting your process? Contact CDT’s Application Engineers at TheGrindingChronicles@cdtusa.net.

Check out more videos from The Grinding Chronicles and follow CDT on Linked In for the latest news in grinding technology.

Continental Diamond Tool to Showcase Gear Grinding Solutions from Krebs & Riedel at Motion + Power 2025

See CDT and Krebs & Riedel at Motion + Power 2025 in Detroit, Michigan, with gear grinding solutions backed by U.S.-based service and engineering expertise.

New Haven, Indiana –September 16, 2025. Continental Diamond Tool Corporation (CDT) announced today details of its upcoming exhibit at the Motion + Power Technology Expo 2025, marking a major milestone as the company showcases an expanded portfolio of grinding solutions. CDT will be exhibiting at Booth 769 at the event, which is produced by the American Gear Manufacturers Association (AGMA) and will take place October 21–23, 2025, at Huntington Place in Detroit, Michigan.