News and Resources

Browse by Category

Browse by Product

- All Dressing Products

- All Grinding Products

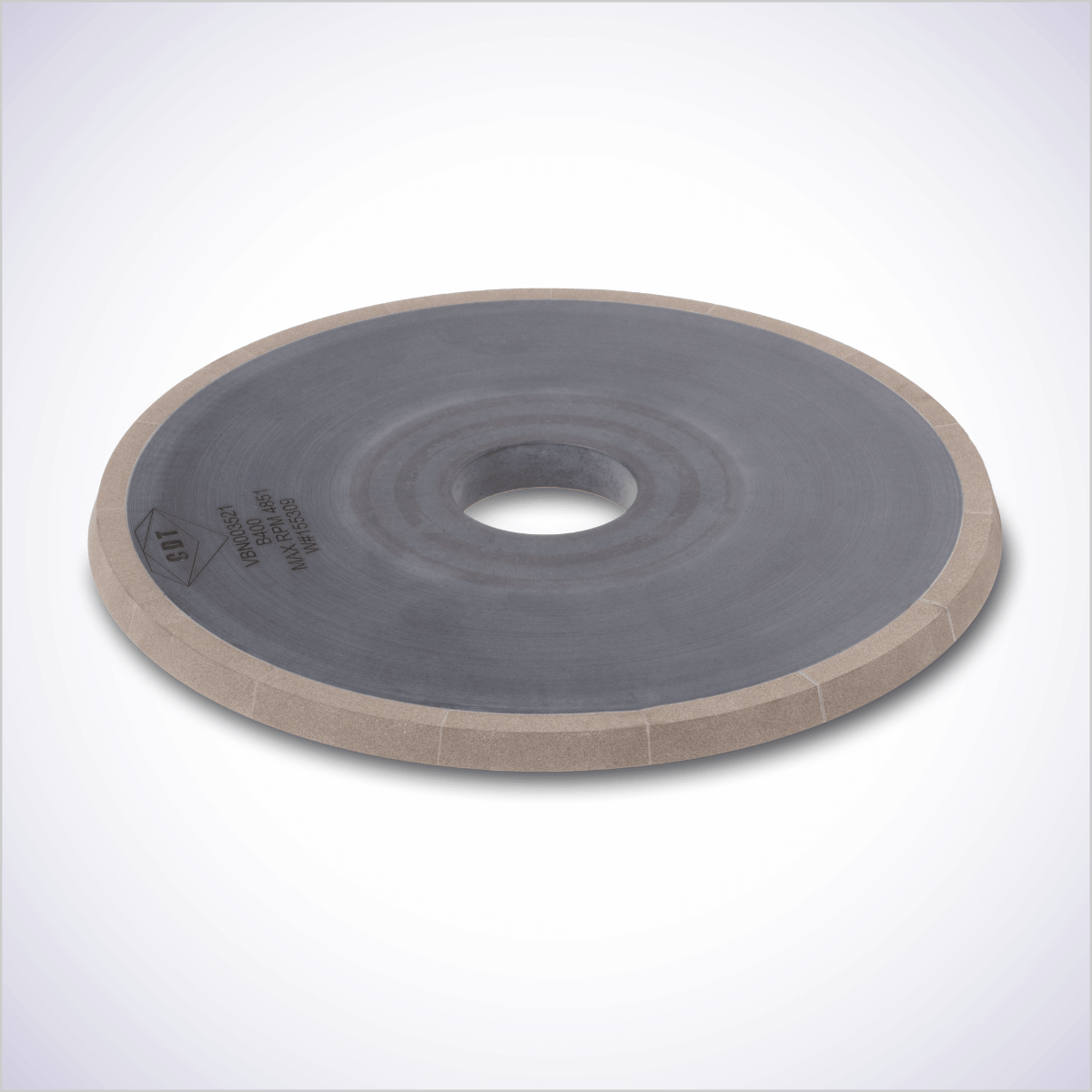

- CBN-Diamond Superabrasives

- Conventional Abrasives

- Diamond Lapping Compounds

- Diamond Rotary Dressers

- Diamond Stationary Dressers

- Hybrid Bond Grinding Tools

- Metal Bond Grinding Tools

- Plated Grinding Tools

- Resin Bond Grinding Tools

- Vitrified Bond Grinding Tools

CDT Officially Opens £4M Kinmel Bay Expansion Amid Record Sales

CDT opens a 30,000 sq ft Kinmel Bay factory in a £4M expansion—doubling capacity and accelerating electro-plated products for customers worldwide.

Continental Diamond Tool in North Wales is celebrating record sales after opening a new state-of-the-art engineering center.

Last week we officially unveiled the 30,000 sq ft plant on the Tir Llwyd Industrial Estate in Kinmel Bay, which is three times the size of the old site just half a mile away.

The move is part of a £4 million expansion plan which will see a 100 per cent increase in production capacity and a doubling of the workforce to 80 staff over the next couple of years.

There have already been benefits for the local economy because most of the contractors used for the fit-out of the new factory are based on the same industrial estate.

Demand is booming for the ultra-precise industrial tooling CDT makes in Kinmel Bay for the aerospace, automotive and oil and gas sectors, including blue chip customers like Rolls Royce, General Electric and Tenneco.

Founded in 1984 as Consort Precision Diamond, this facility's high precision diamond rotary dressing products were turbocharged after being acquired by CDT in 2018.

Nick Viggiano, Continental Diamond Tool’s President, attended the official opening along with senior executives who travelled over from the American headquarters in New Haven in Indiana.

Nick said: “This is a very proud moment to come over here and see how things have been transformed, from the factory it was before to this new space. This is wonderful.

“I think the employees feel it, and you can see in their faces they enjoy working in this new environment. I am sure we will see a great return on our investment.

“The people here are willing to try new things and push to the next level. The commitment of the team in Kinmel Bay has been a big reason behind the investment.

“We like to press forward fast and have fun doing it. I think it’s going to go really well.

“The introduction of our new electro-plated products has been a big success, and I expect they will outgrow everything else we make in this building in the next five years.”

As well as expanding the product range, CDT is breaking through into new international markets in the Middle East, Mexico and Poland where new sales teams have been established.

General manager Troy Giachero said: “One of the main reasons for our success here is the way the Welsh workforce has dovetailed with their American colleagues. Team work is everything.

“You have to invest in the people and invest in the training. We have a lot of experts on both sides of the Atlantic and the combination has enabled us to grow at the pace we have.”

He added: “One thing I’m particularly proud of is that the electric, the plumbing and the air supply for our machines was all provided by contractors on this very industrial estate.

“All the money we’ve put into this building in fitting it out was invested locally and will stay in this area, so this has helped out the local community and Wales as a whole.”

Support from the Welsh Government and Conwy County Borough Council has been key, with £100,000 from the UK Shared Prosperity Fund to help purchase new equipment.

Council Leader Cllr Charlie McCoubrey said: “It’s really impressive to see such high tech industry in Kinmel Bay, bringing really well paid jobs into this area.

“We know that SMEs are vitally important in Conwy and to see an organisation like this growing organically is fantastic with their products being exported across the world.”

It was a sentiment echoed by Cllr Nigel Smith, Conwy Council’s cabinet member for Sustainable Economy, who represents Kinmel Bay on the authority.

He said: “This investment by the American owners is most welcome. To see the transformation here today is absolutely amazing.

“There’s huge potential for growth because CDT are international market leaders. The future is very exciting for the town of Kinmel Bay, the county of Conwy and for North Wales.”

The honour of cutting the ribbon to officially open the new factory went to long-serving production manager Justin Hughes who masterminded the transfer of 100 tonnes of equipment to the new site.

He said: “We really hit the ground running when we moved here. The move from one building to the other was so smooth because we used the right people to do the job and the team went above and beyond to make it happen seamlessly.

“We’ve also had brilliant support from our American colleagues who have done this kind of thing before in the States so we really benefited from the lessons they had learned.

“We are already reaping the benefits. Our order book is the highest it has ever been and it’s only going in one direction and doing so very fast.

“We have more investment coming down the track, expanding our capability with the electro-plated lines. We now have space to keep on growing.”

Among the VIP guests were two of the original company’s founders, Steve Noakes and Peter Hughes, Justin’s father.

Sadly, one of the other founders, Dave Morris, the former managing director, passed away recently.

Mr Hughes said: “When the company was acquired, Dave was made up and he would have been absolutely over the moon to have been here today. He would have been so pleased.

“I’m also delighted to see how successful the company is and I am particularly proud of the part Justin is playing. He loves it and I am so chuffed for him.”

Related Links:

https://businessnewswales.com/north-wales-engineering-firm-unveils-new-30000-sq-ft-facility/

https://www.baysideradio.co.uk/news/expansion-sparks-record-growth-for-kinmel-bay-firm-11155

https://www.wales247.co.uk/continental-diamond-tool-unveils-4m-factory-to-meet-global-demand

https://www.welshnewsextra.com/boom-time-for-north-wales-firm-as-4m-expansion-sparks-record-sales/

Continental Diamond Tool Limited (CDT Ltd.), based in Kinmel Bay, Rhyl, U.K., is the European subsidiary of Continental Diamond Tool Corporation, headquartered in New Haven, Indiana, U.S.A. For more than 40 years, CDT Ltd. has been a leader in diamond rotary dresser technology, originally operating as Consort Precision Diamond. Since joining CDT, the company has expanded its product line, delivering high-performance diamond plated grinding wheels and other premium superabrasive products to customers worldwide.

Continental Diamond Tool to Showcase Gear Grinding Solutions from Krebs & Riedel at Motion + Power 2025

See CDT and Krebs & Riedel at Motion + Power 2025 in Detroit, Michigan, with gear grinding solutions backed by U.S.-based service and engineering expertise.

New Haven, Indiana –September 16, 2025. Continental Diamond Tool Corporation (CDT) announced today details of its upcoming exhibit at the Motion + Power Technology Expo 2025, marking a major milestone as the company showcases an expanded portfolio of grinding solutions. CDT will be exhibiting at Booth 769 at the event, which is produced by the American Gear Manufacturers Association (AGMA) and will take place October 21–23, 2025, at Huntington Place in Detroit, Michigan.

This event will be CDT’s first major industry exhibition featuring Krebs & Riedel products since becoming the exclusive North American partner of the German-based abrasive manufacturer in 2024. The collaboration gives customers in the U.S., Canada, and Mexico faster access to Krebs & Riedel’s conventional abrasive grinding wheels, backed by CDT’s custom profiling services and application engineering expertise.

Entering the Gear Grinding Market

Motion + Power 2025 also represents CDT’s public entry into the gear grinding market. To support this expansion, CDT has invested in the Burri PM550T profile grinding machine, enabling precise wheel profiling and faster turnaround times for gear manufacturers. This addition underscores CDT’s commitment to providing gear shops with locally supported, high-performance grinding solutions.

Full Lineup of Grinding Solutions

In addition to Krebs & Riedel’s conventional abrasive wheels, CDT will showcase its Vitrified CBN grinding wheels and Diamond Rotary Dressers, both designed to deliver higher efficiency, longer tool life, and improved precision for demanding applications. Together, these offerings provide manufacturers with a comprehensive range of abrasive technologies—whether the application calls for conventional abrasives or superabrasive solutions.

Delivering Value Through Partnership

By combining CDT’s application expertise and U.S. based inventory, with Krebs & Riedel’s 140 years of innovation in bonded abrasives, manufacturers gain:

Faster access to premium conventional wheels through local stocking and distribution.

Custom profiling services to meet gear grinding and other complex application needs.

Integrated solutions that allow customers to seamlessly transition between conventional and superabrasive technologies.

Technical support from CDT’s engineering team to improve productivity, reduce downtime, and achieve consistent results.

“Motion + Power 2025 is an ideal platform to demonstrate how this partnership benefits our customers,” said Erik Van Meter, CDT Product Line Manager for Conventional Abrasives. “By uniting CDT’s technical service and local capabilities with Krebs & Riedel’s world-class products, we’re giving manufacturers the grinding solutions they need—delivered faster and supported by experts who understand their processes.”

About Continental Diamond Tool Corporation

Founded in 1973, Continental Diamond Tool Corporation (CDT) is a leading manufacturer of custom superabrasive grinding wheels and diamond dressing tools. From its state-of-the-art 200,000 sq. ft. facility in New Haven, Indiana, CDT serves a wide range of industries including aerospace, automotive, medical, and general manufacturing.

About Krebs & Riedel

Founded in 1885, Krebs & Riedel is a family-owned company and a global leader in bonded abrasives. Headquartered in Bad Karlshafen, Germany, the company provides conventional grinding wheels to more than 30 countries worldwide, known for their precision, performance, and reliability.

For more information about CDT’s products and Motion + Power 2025 presence, visit www.cdtusa.net.

Grinding Solutions for the Unique Challenges of Aerospace

CDT’s aerospace grinding solutions improve precision, reduce downtime, and handle tough alloys, composites, and ceramics for reliable flight performance.

Tailoring Grinding Solutions for the Unique Challenges of Aerospace

In aerospace manufacturing, precision grinding is essential for producing components that must reliably perform under extreme conditions. Whether it’s turbine blades, vanes, or structural parts, these components require tight tolerances, exceptional surface finishes, and consistent performance—all while being made from some of the most challenging materials to grind, such as nickel-based superalloys, titanium, and ceramic matrix composites (CMCs).

The grinding process must balance aggressive material removal, heat management, and tool wear resistance to achieve the required part quality and efficiency. This is where electroplated grinding wheels and diamond rotary dressers provide significant advantages, offering solutions to some of the most persistent challenges in aerospace grinding.

Evolving Challenges in Aerospace Manufacturing

Aerospace manufacturers are continuously refining their production processes to meet increasing performance demands. Several industry trends are shaping the way grinding solutions must adapt:

Advanced Materials Require New Machining Strategies

The use of lightweight, high-strength materials such as carbon fiber composites, aluminum-lithium alloys, and CMCs is growing. These materials improve fuel efficiency without sacrificing structural integrity. However, their brittleness, heat sensitivity, and abrasiveness present machining challenges that require specialized grinding technology to shape them.

Additive Manufacturing Is Changing Component Design

3D-printed aerospace parts often require post-processing to achieve dimensional accuracy and surface integrity. Superabrasive grinding wheels are particularly well-suited for refining these components without inducing stress or altering their properties.

Rising Demand for High-Precision Parts

Increasing global defense spending and increased commercial air travel require manufacturers to produce high-performance components at scale, making efficient and repeatable grinding solutions more critical than ever.

Space Exploration Is Pushing Material Science Forward

New materials developed for satellite technology and space vehicles require grinding solutions that can maintain precision while working with ultra-hard alloys and ceramics, materials designed to withstand the extreme conditions of space.

With these challenges in mind, engineering the right grinding wheel is more critical than ever for ensuring part quality, process efficiency, and long-term performance in aerospace applications.

The Role of Electroplated Grinding Wheels in Aerospace

Electroplated grinding wheels offer a unique advantage in aerospace manufacturing due to their single-layer abrasive structure, aggressive cutting action, and ability to maintain form without dressing. Unlike bonded grinding wheels, where abrasive grains are embedded within a matrix, electroplated wheels expose a full layer of diamond or cBN material, ensuring sharp cutting edges and consistent performance.

How Electroplated Grinding Wheels Address Aerospace Challenges

✔ Maintaining Profile Accuracy: Electroplated wheels hold complex geometries without needing dressing, making them ideal for intricate aerospace components.

✔ High Stock Removal with Minimal Heat Generation: The open structure of electroplated wheels allows for aggressive material removal while features like coolant slots and through the wheel coolant delivery can be added to reduce heat buildup—critical when working with heat-sensitive materials like titanium.

✔ Custom-Engineered for the Application and Material: Abrasive size and type, core accuracy, and uniform plating are all critical to match unique aerospace grinding requirements.

✔ Longer Tool Life, Less Downtime: Electroplated wheels maintain their shape throughout their lifespan, eliminating the need for dressing and reducing machine downtime.

✔ Cost Savings with Strip and Replate Services: CDT offers a customized strip and replate program that allow customers to reuse the same core, reducing costs and lead times while delivering the same high-level performance. Our strip technology safely removes remaining abrasive without damaging the core and returns the tool to “like new” condition after replating. This makes it a more cost-effective and sustainable solution for aerospace manufacturers running frequent grinding operations.

"Electroplated grinding wheels are a great fit for aerospace because they are both precision and efficient. They hold intricate profiles, handle high speeds, and stand up against tough materials like nickel alloys, titanium, and ceramics — plus, with our strip and replate services, customers can extend the life of their tools and keep costs down without sacrificing performance," says Jordan Donnelly, CDT Product Line Manager for Electroplated Products.

Optimizing Grinding Performance with Diamond Rotary Dressers

Precision grinding requires continuous wheel maintenance to ensure optimal cutting efficiency and part consistency. Diamond rotary dressers are essential in aerospace manufacturing for truing and conditioning grinding wheels, ensuring the reliability and accuracy of the grinding process.

Key Benefits of Diamond Rotary Dressers in Aerospace

✔ Consistency Across High-Volume Production: Rotary dressers keep grinding wheels performing uniformly, ensuring part consistency and accuracy from the first to the last component.

✔ Reducing Cycle Times & Increasing Efficiency: Keeping wheels properly conditioned and sharp, minimizes grinding forces and allows for optimum cycle times while maintaining part quality.

✔ Application-Specific Design: Whether the application requires traverse or plunge-style dressing, CDT custom-designs each rotary dresser to specific customer needs and applications.

✔ Manufacturing Customization: Every application is different, thus requiring different solutions. CDT solves this issue by offering sintered, reverseplated, and metal bonded rotary dressers.

"Consistency is everything in aerospace manufacturing. Even the smallest deviation can throw off performance, which is why rotary dressing is so important. Our custom-engineered dressers keep grinding wheels precise and reliable, helping manufacturers get accurate, repeatable results every time," explains Troy Giacherio, CDT Product Line Manager for Diamond Rotary Dressers.

The Advantage of a Multi-Disciplinary Grinding Expertise

While electroplated grinding wheels and diamond rotary dressers provide high-performance solutions, CDT’s expertise extends beyond these technologies—allowing us to approach aerospace grinding challenges from multiple angles.

We have extensive experience working with a variety of:

Bond Types: Plated, resin bond, metal bond, vitrified bond, hybrid bond

Core Materials: Carbon fiber, ceramic, high-tensile strength steel, and many more

Diamond Patterns: Handset, random set, reverse plated, CVD-reinforced

Abrasives: Diamond, cBN, and conventional abrasive grinding solutions

This broad expertise enables CDT to study materials, test performance, and develop tailored grinding solutions that push the boundaries of what’s possible. Our dedicated grinding lab allows us to simulate real-world aerospace applications, testing how new materials react during grinding and refining wheel designs to optimize performance.

This cross-industry experience from both the product and application side fosters innovation, ensuring that we don’t just provide grinding wheels—we provide solutions tailored to the specific needs of aerospace manufacturers.

Expanding Capabilities to Better Supply the Aerospace Industry

To address increasing global demand for aerospace products, CDT is expanding its electroplated grinding wheel production capacity with a new building that will grow its second plating line in Europe. This expansion will increase production efficiency, reduce lead times, and allow CDT to serve aerospace manufacturers at a larger scale.

"Expanding our plating facility is a big step forward. With the new electroplating line, we can speed up production and handle more capacity, getting products delivered faster. It’s all part of CDT’s commitment to innovation and supporting the growing needs of our aerospace customers," says Justin Hughes, Production Manager at CDT Ltd.

Finding the Right Grinding Solution for Aerospace Manufacturing

The challenges of aerospace manufacturing—tough materials, tight tolerances, and growing demand—require advanced grinding solutions that can maintain precision, minimize downtime, and innovate at speed and scale.

With specialized knowledge in electroplated diamond and cBN grinding wheels, advanced diamond rotary dresser technology, and expertise across many other grinding product types, CDT is uniquely positioned to help aerospace manufacturers optimize production processes and innovate for the future.

Contact us today to discuss how CDT’s precision grinding solutions can help optimize your aerospace manufacturing process.

Continental Diamond Tool Limited (CDT Ltd.), based in Kinmel Bay, Rhyl, U.K., is the European subsidiary of Continental Diamond Tool Corporation, headquartered in New Haven, Indiana, U.S.A. For more than 40 years, CDT Ltd. has been a leader in diamond rotary dresser technology, originally operating as Consort Precision Diamond. Since joining CDT, the company has expanded its product line, delivering high-performance diamond plated grinding wheels and other premium superabrasive products to customers worldwide.

CDT’s £4 million move in Wales sparks jobs boom and global growth

Continental Diamond Tool’s Kinmel Bay team moves into a new facility triple the size, boosting capacity for plated products.

Continental Diamond Tool in North Wales is celebrating a major transformation after moving to a purpose-built facility — unlocking massive growth potential and creating dozens of new jobs.

CDT has successfully relocated to a new 30,000 sq ft factory in Kinmel Bay after what managers described as a “logistical challenge on par with a military operation.”

The operation involved transporting more than 100 metric tonnes of machinery and equipment to the new base that’s nearly three times the size of its old premises less than half a mile away on the Tir Llwyd Industrial Estate.

The move is part of a £4 million expansion by the company which custom engineers ultra-precise industrial tooling for the aerospace, automotive and oil and gas sectors. Blue chip customers include Rolls Royce, Airbus and Tenneco.

Originally established as Consort Precision Diamond in 1984, the company was acquired and rebranded by American-owned Continental Diamond Tool in 2018.

Production Manager Justin Hughes, whose father, Peter, was a founding member of the business, said the move marks the beginning of an exciting new chapter for the company.

“There is a new ambition along with the investment,” said Justin, who has worked at CDT for 18 years. “The future is bright.”

The relocation was carried out with precise planning to minimise disruption, with some production lines back in operation in less than a week.

“In three days they had transported pretty much all the machinery out of the old factory into the new one,” he said. “Production was down for a maximum of two weeks for certain products, but for others the down time was less than a week.”

The company brought in help from key suppliers, including Mills CNC, and received support from CDT’s American owners, who have overseen multiple factory expansions in the United States.

“We had help from one of our American colleagues, facility manager Mike Moehring, who even brought forward his exit flight because it had gone so smoothly,” said Justin.

“This isn’t the company’s first rodeo. They’ve helped us get things right the first time — and that’s been absolutely invaluable.”

With 46 staff currently on site, the company now plans to grow the workforce to around 80 employees over the next two years, with a major recruitment and investment push underway — particularly in the electro-plating department.

“We could only fit 14 electro-plating tanks in our old premises,” Justin explained. “Here we can accommodate up to 200. It’s the perfect environment – less humid, well-ventilated, and much more comfortable for staff.”

CDT is investing £500,000 in new equipment, and the improved capacity is already paying off.

International orders are growing and the company now has the ability to manufacture five times as many large parts per day and thousands of small parts per week, many destined for the oil and gas industry.

“We used to have to turn away orders because we just didn’t have the capacity,” said Justin. “Now we can meet that demand — and electro-plated products are on course to become the biggest part of our business.”

The company is also expanding into Poland, which Justin describes as a “manufacturing powerhouse.”

The new facility has been designed with staff welfare in mind, with a new canteen and bright, modern working conditions aimed at both retaining current staff and attracting new recruits.

“It feels like we’ve moved out of the dark ages into the 21st century,” he added. “We’ve always been capable — now we have the tools and the space to reach our full potential.”

Among the longest-serving staff is Joe Bowles, 35, from Rhyl, who began his career as an apprentice and is now CDT’s Grinding Supervisor.

“The company has grown bigger but it still feels like a family,” said Joe. “The American owners have put real money into the business and upgraded our machines – it’s a huge vote of confidence in the Kinmel Bay operation.”

Joe, a third-generation engineer, takes pride in the firm’s commitment to quality.

“Everything is inspected two or three times. Our tolerances are normally within 10 microns – a red blood cell is five microns – and sometimes we work to just a single micron. That’s how precise we are.”

For newer members of the team, the relocation was seamless. Nori Aknai, 38, originally from Hungary and now living in Rhyl, joined CDT three months ago as a finance assistant.

“I really do like it here,” she said. “The move was huge but it went incredibly smoothly. Literally, we were working in the old place one day and the following morning we came here and everything was working. The fact that it’s a growing company means it’s an exciting place to work.”

Now firmly settled in their new home, CDT is looking to the future with optimism.

“I’m very proud of what we have achieved,” said Justin. “We’ve laid the foundations to do something really special here in Kinmel Bay.”

Continental Diamond Tool Limited (CDT Ltd.), based in Kinmel Bay, Rhyl, U.K., is the European subsidiary of Continental Diamond Tool Corporation, headquartered in New Haven, Indiana, U.S.A. For more than 40 years, CDT Ltd. has been a leader in diamond rotary dresser technology, originally operating as Consort Precision Diamond. Since joining CDT, the company has expanded its product line, delivering high-performance diamond plated grinding wheels and other premium superabrasive products to customers worldwide.

Related Links

https://businessnewswales.com/north-wales-manufacturers-4m-expansion-boosts-jobs-and-growth/

https://www.rhyljournal.co.uk/news/25415816.kinmel-bay-firms-4million-relocation-sparks-jobs-boom/

https://www.wales247.co.uk/north-wales-firms-4-million-move-sparks-jobs-boom-and-global-growth

https://www.welshnewsextra.com/north-wales-firms-4-million-move-sparks-jobs-boom-and-global-growth/

Profile vs. Surface Finish: Identifying the Limiting Factor in Your Grinding Process

Learn how to identify whether profile or surface finish is limiting your grinding process—and how to use that insight to reduce scrap and optimize performance.

Scrap is costly—both in time and materials. If you’re looking to improve quality and reduce waste, it’s essential to identify what’s holding your process back. In Episode 12 of The Grinding Chronicles, CDT Application Engineer Blu Conrad shares how measuring profile and surface finish can help pinpoint the root cause of your quality issues. Watch the video or read on to learn how to address these limiting factors and run a more efficient grinding operation.

The Grinding Chronicles - Episode 12

Why Your Parts Are Going Out of Spec — And How to Fix It: Part 1

Efficient grinding operations—especially at scale—depend on consistency to stay competitive. When parts start falling out of spec, the impact is immediate: lost time, wasted material, and rising costs. Two of the most common culprits are profile deterioration and surface finish breakdown. But how can you tell which one is actually limiting your process?

A targeted approach to tracking part quality can reveal the answer—and help you set the ideal dressing interval for your wheel.

Profile and Surface Finish: Understanding the Distinction

In grinding, profile refers to the macro geometry your wheel produces—the shape and dimensional accuracy of the part. Surface finish, on the other hand, captures the micro-level texture or roughness on the surface. Both play a critical role in quality, but they degrade differently and can indicate different underlying problems.

Track the Right Data

One of the most effective ways to diagnose which factor is causing your parts to fail is to measure both profile and finish at regular intervals. For example, take a measurement every five or ten parts and record that data alongside the volume of material removed.

Plotting those measurements on a graph—with volume ground on the horizontal axis and profile or finish on the vertical axis—will give you a clear picture of which element goes out of tolerance first.

“Whichever set of data crosses out of tolerance first—that’s your constraint,” says Blu Conrad, Application Engineer at CDT. “That tells you where your process is breaking down and where to focus your efforts.”

If profile is causing you to fall out of spec first, your dressing interval should be set based on that. If surface finish is the issue, your remedies need to shift toward surface-related variables.

If Profile is the Problem

When profile is the limiting factor, excessive force per grit is often to blame. This can occur when the wheel-work contact length is short, meaning fewer cutting edges are engaged and each grit is doing more work. Over time, this accelerates wear and throws the wheel out of shape.

In cases like this, upgrading to a more robust grinding wheel can help. A harder abrasive or more durable bond may provide better resistance to wear and extend the life of the wheel between dressing cycles.

But before you swap out tooling, it’s important to rule out other contributors—especially coolant. Inadequate coolant flow or misaligned nozzles can rapidly accelerate wheel wear and distort profile accuracy.

“It’s not always the wheel’s fault,” Blu explains. “Sometimes just optimizing your coolant delivery can make a huge difference in how long your profile holds.”

To learn more about effective coolant application, check out The Grinding Chronicles Episode 3, where Blu breaks down four key factors—velocity, flow, line placement, and temperature—and how each one affects wheel performance and part quality.

If Surface Finish is the Issue

In some processes, the surface finish goes out of spec before the profile ever does. This points to different limitations—often related to speed, feed, wheel dressing parameters, or wheel condition.

In an upcoming video later this year, we will walk through how to predict surface finish with a simple calculation and explain what changes you can make to improve results. Subscribe to our YouTube Channel to catch the release.

Make Your Dressing Interval Work for You

Scrap is always costly—but it’s also avoidable with the right analysis. By identifying whether profile or finish is the first to fail, you gain control over your process. You can set a purposeful dressing schedule that reduces unnecessary wheel wear, increases uptime, and keeps parts in spec for longer. After all, both profile and finish will eventually degrade—it’s not a matter of if, but when—so knowing which factor breaks down first lets you plan more strategically.

Need help dialing in your own dressing interval? Contact CDT’s Application Engineering team at TheGrindingChronicles@cdtusa.net or visit cdtusa.net/the-grinding-chronicles for more grinding insights.

Check out more videos from The Grinding Chronicles and follow CDT on Linked In for the latest news in grinding technology.

Breaking from the Conventional: How Vitrified CBN Wheels Excel on Studer Equipment

Vitrified CBN wheels improve performance, reduce downtime, and enable lights-out grinding on Studer machines. Learn more in CDT’s latest blog.

At Continental Diamond Tool, we frequently manufacture Vitrified CBN wheels for widely used grinding platforms such as the Studer S33, FavoritCNC, and S131r. While many operations still rely on conventional abrasives, Vitrified Bond CBN is increasingly the go-to solution for high-precision, high-volume grinding applications—and for good reason.

If your shop is pushing for tighter tolerances, longer tool life, or lights-out production, here's why this technology may be the right move.

Why Choose Vitrified CBN?

When grinding hardened steels and other ferrous materials, Vitrified CBN (Cubic Boron Nitride) wheels offer significant advantages over traditional abrasives like aluminum oxide, which are commonly used for similar applications:

100–300× Longer Wheel Life

Vitrified CBN outlasts conventional wheels by a wide margin, reducing the frequency of wheel changes and downtime.Tighter Tolerance Control

These wheels maintain form exceptionally well, ensuring consistent part geometry even across extended production runs.Cooler, Cleaner Cutting

The vitrified bond provides superior chip clearance and heat dissipation, minimizing the risk of thermal damage and improving surface finish.Ideal for Lights-Out Operation

Extended wheel life, consistent performance, and reduced need for manual intervention make Vitrified CBN wheels a great match for automated and lights-out environments.

“If you are dressing properly with a diamond rotary dresser, your vitrified CBN wheel will last a very long time—and you’ll produce high-quality parts at a great pace with little to no variation,” says Troy Giacherio, CDT’s Product Line Manager for Rotary Dressers.

Rotary Dressing Techniques for Vitrified CBN

Dressing is essential for maintaining wheel shape and exposing fresh cutting edges—but how often and how efficiently you can dress the wheel makes a big difference in productivity.

Conventional Abrasive Wheels

These wear down quickly and require frequent dressing to restore geometry and surface integrity.Vitrified CBN Wheels

Thanks to their exceptional wear resistance, these wheels require dressing far less frequently. When dressing is needed, rotary diamond dressers are the tool of choice.

At CDT, we manufacture rotary diamond dressers tailored to your process, whether using conventional or Vitrified CBN wheels. For vitrified applications, these dressers enable precise, programmable dressing that fits seamlessly into automated processes—reducing operator time and increasing repeatability.

“If you’re transitioning from conventional abrasives to CBN—or if you’re seeing issues like burn or finish patterns—you might not be dressing your wheel correctly,” says Troy. “If your power draw starts creeping up or you see changes in surface finish, that’s your cue—it’s time to dress the wheel.”

Want to learn more about dressing Vitrified Bond CBN wheels with a rotary diamond dresser? Watch Episode 5 of The Grinding Chronicles, where Troy breaks down key dressing parameters like velocity ratio, overlap ratio, and depth of dress.

Top Signs You Should Be Using Vitrified CBN Wheels Instead of Conventional Abrasives

If your current process is held back by:

Frequent dressing and wheel changes

Inconsistent size or surface finish

Excessive heat generation

Limited machine uptime or operator availability

…it may be time to evaluate a Vitrified CBN solution. Especially when paired with capable machines like the Studer S33, FavoritCNC, and S131r, CBN technology can unlock new levels of efficiency and reliability.

“When switching from conventional wheels to vitrified CBN wheels, we’ve seen dress intervals go from a few parts to hundreds,” says Troy. “The key is balancing efficiency with consistency to get the most life out of your wheel and performance from your process.”

Whether you’re looking to reduce cost per part, improve part quality, or enable lights-out production, switching to Vitrified CBN may be the upgrade your process needs.

See CDT Wheels in Action: United Grinding Precision Summit

Curious how Vitrified CBN performs in a real-world environment?

Join us July 29–30 at the United Grinding Precision Summit, where CDT has supplied wheels on these three Studer machines: the S33, FavoritCNC, and S131r.

You’ll have the opportunity to meet our engineers, discuss dressing techniques and process parameters, and explore how customized Vitrified CBN wheels can enhance your operations.

👉 RSVP now at united.grinding.com/theprecisionsummit2025

Making the Switch from Conventional Abrasives to CBN

Ready to explore Vitrified CBN Wheels and Diamond Rotary Dressers? At CDT, our sales team includes dedicated process engineers who work directly with customers to assess grinding setups, identify improvement opportunities, and develop optimized solutions tailored to today’s most advanced platforms.

Whether you're running a Studer S33, FavoritCNC, or S131r, or comparable machines from Kellenberger, Bryant, or Okuma, CDT has the tools and technical expertise to support your production goals. We help manufacturers across industries transition from conventional abrasives to high-performance vitrified CBN—delivering better form retention, reduced dressing, and longer wheel life.

📞 Call us at 1-800-443-6629 or contact us online to get in touch with a CDT expert and find the right grinding solution for your application.

Improving Part Quality and Reducing Costs in Medical Grinding

Discover how CDT helps medical manufacturers improve part quality, reduce scrap, and cut costs with custom-engineered grinding wheel solutions.

In medical manufacturing, even small inconsistencies in components like implants, surgical tools, or drill bits can lead to costly failures and compromised safety. Precision and reliability aren't just goals—they're required for industry standards and FDA approval. Yet it’s common for manufacturers to struggle with persistent issues like inconsistent surface finishes, excessive burr formation, and unpredictable wheel performance that increase scrap and labor costs.

At Continental Diamond Tool (CDT), we understand the root causes behind these challenges and help medical manufacturers overcome them through targeted, reliable, custom engineered grinding solutions.

One of CDT’s biggest strengths is how closely our sales and engineering teams work together—often as the same people. Many of our team members serve dual roles, combining application expertise with customer-facing support, so the person helping you select your wheel also understands how to fine-tune it for maximum performance.

“The most important factor for medical suppliers is part quality,” says Blu Conrad, CDT Application Engineer who specializes in medical manufacturing support. ”When we see issues like burrs, poor finishes, or short wheel life, it’s usually a sign that there is a problem with the wheel or process set up. We can help you fix that.”

CDT’s vitrified CBN wheels provide reliable, repeatable performance when grinding complex medical components like surgical drill bits.

Is Your Grinding Process Hurting Your Productivity?

Do you face problems like:

Inconsistent surface finishes and part quality?

Excessive manual deburring labor due to excessive burr formation?

Short wheel life and frequent dressing?

Difficulties maintaining tight tolerances and precise geometries?

These problems often come down to using a grinding wheel or machine settings that are not optimized for your application. At CDT, we take a hands-on, data-driven approach to help you pick the right wheel and adjust your set up — so you can count on consistent, reliable performance that fits the way you work.

Specialized Grinding Wheels Designed for the Medical Industry

CDT specializes in designing, developing, and delivering custom-engineered diamond and cBN grinding wheels for all types of medical manufacturing. While we have seven unique product lines, there are three distinct grinding wheel types that we commonly specify for medical manufacturers:

Plated Wheels: Perfect for roughing operations, plated wheels maintain precise profiles — like those required on complex medical implants and surgical cutting tools — for the entire life of the wheel with no dressing required. We also offer a strip and replate program that reuses your wheel core and reapplies the abrasive—restoring it to like-new condition at a fraction of the cost.

Vitrified CBN Wheels: Often found in finishing operations, these wheels minimize burr formation and ensure consistent, high-quality results. Best used with machines featuring onboard wheel dressers, vitrified cBN wheels are particularly cost effective for manufacturers who are taking advantage of lights out operation. CDT also manufactures the onboard Diamond Rotary Dressers that keep these wheels efficiently grinding at peak performance.

Hybrid Bond Wheels: A variation of CDT's resin bond grinding wheels, our EVO Hybrid Bond formula provides excellent shape retention, consistent free cutting, and reduced heat buildup. We often recommend this product line for finishing medical parts on machines where operators manually dress the wheel.

“We’ve helped customers reduce cycle times by up to 20%,” recalls Blu. “And just as important, we’ve been able to significantly cut down on manual deburring labor—especially when they switch to vitrified CBN wheels paired with onboard wheel dressers that run cleaner and cooler with less downtime than manual dressing.”

Proven Solutions Across Leading Machines and Materials

CDT grinding wheels are designed to perform on leading medical manufacturing machines, including platforms from Walter, Rollomatic, Schütte, Starr, and Strausak. Whether you're a large OEM or a contract manufacturer, we tailor each wheel to your production requirements.

“Medical components are often made from stainless steels like 17-4 or 455, which can be tricky,” Blu explains. “They’re gummy and prone to burrs. That’s why we pay close attention to both the material and the machine setup when we spec a wheel.”

Our team takes material properties—such as ductility and hardness—into account when developing wheels. Stainless steels are particularly prone to heat buildup and burrs. With the right wheel and setup, we can significantly reduce these effects, helping customers reduce scrap and minimize secondary deburring processes.

Your Trusted Guide for Long-Term Success

CDT isn't just a wheel supplier; we're your strategic partner in precision grinding. Our team proactively collaborates with you from new product prototyping to established production optimization, ensuring your processes are finely tuned and continuously efficient.

We can also help you evaluate machine options—well before it's time to order your grinding wheel. “It’s more common than it should be for us to get called in after a machine is already purchased,” says Blu. “We love to be part of the conversation earlier because features like onboard dressers make a huge difference. We’ve had customers retrofit onboard dresser technology just to unlock the full performance of a vitrified CBN wheel.”

In addition, our grinding lab is a valuable resource for customers. They can safely explore the performance limits of their wheels and identify opportunities for improvement without interrupting production or incurring the cost of scrap and downtime. We also offer a portable lab to diagnose system inefficiencies directly at the production site.”

From implants to surgical tools, CDT Application Engineer Blu Conrad specializes in helping medical manufacturers improve precision, reduce scrap, and save time. Reach out today.

Why Medical Manufacturers Trust CDT

Medical manufacturers consistently choose CDT because we deliver:

Rapid turnaround and reliable lead times

Dependable quality, performance, and cost-efficiency

Hands-on technical support, troubleshooting, and training for your operators

Expert R&D engineering services focused on helping you succeed

Don’t let grinding wheel issues compromise the quality or productivity of your medical manufacturing operations. Take control of your process and partner with CDT to confidently meet your critical manufacturing goals.

Ready to transform your grinding process? Contact Blu Conrad and others on the CDT sales team today for a free consultation and quote. Call 1-800-443-6629 or visit our webform to get started.

CDT Targets Growth in Eastern Europe with Sales Presence in Poland

Continental Diamond Tool expands into Poland, bringing high-performance grinding wheels and diamond dressers to the region’s growing aerospace and automotive industries.

Continental Diamond Tool is targeting major sales growth in Eastern Europe after launching our first sales force in Poland.

Leading the team is Mariusz Kowalski, our new Sales Manager for Poland, who is spearheading a drive for new orders on behalf of Continental Diamond Tool (CDT).

CDT supplies precision tooling for Tier 1 aerospace and automotive companies, specialising in designing and producing high‑spec grinding wheels for advanced manufacturing processes. Our product range includes diamond‑encrusted rotary dressers, accurate to within one‑thousandth of a millimetre.

We have also ramped up the manufacture of new electroplated grinding wheels and tools thanks to a £250,000 investment in cutting‑edge equipment at our Kinmel Bay location.

CDT sees huge opportunities to supply new customers in the rapidly developing engineering sector in Poland and other Eastern European countries.

The move is part of a £4 million expansion that will triple production and double our workforce in Kinmel Bay to 80.

As part of the strategy, we will move later this year to a new 30,000 sq ft factory—three times the size of our current premises—less than half a mile away on the Tir Llwyd Industrial Estate.

Mr Kowalski graduated with a Master of Science from Warsaw University of Technology, specialising in Mechatronics Engineering, which combines mechanical, electrical, computer engineering and robotics to create innovative and complex systems.

Before joining CDT he spent most of his career at Fanar, a Polish leader in machining‑tool manufacturing, where he rose through the ranks and developed new grinding and welding processes.

Now representing CDT from Łomianki—about 20 miles west of Warsaw—he said:

“The new plant in Kinmel Bay will generate more products and a larger production volume, putting us in a perfect spot to support what’s happening here in Poland.

“The Polish market in terms of advanced manufacturing in particular is the fastest-growing in Europe with aerospace companies like Pratt and Whitney and General Electric already in Poland and the country has its own rapidly growing engineering sector which we can service.

“Poland is also attractive to European Union countries like Germany and France because it has a well-educated and skilled workforce, lower costs and is more flexible.

“It also has between 30 and 40 tool-making companies and that’s a market we are also focusing on along with the automotive sector.

“Poland has a lot of engineering companies popping up every day and they’re growing fast.

“I believe that in 10 years’ time Poland could be a world leader in high tech for aerospace, automotive and the medical science industries and CDT can be part of that.

“With our modern factory in Kinmel Bay due to come on line later this year and our operation in the USA in five years’ time we could be looking at a market worth £80 million to the company.

“It is early days for us here in Poland but every day we learn more and make new contacts.

“It’s a fast developing country. Twenty years ago we had 20 per cent unemployment but now it’s below five per cent and the economy is booming.”

CDT’s European division is also seeing business boom, with sales of our new electroplated grinding products rocketing by 960 per cent over the past two years.

We expect electroplated products to outsell rotary dressers within a few years as orders continue to increase, and the move into Poland should only boost demand.

We already export 50 per cent of our turnover from the U.K., with electroplated grinding products reaching beyond Europe into the Middle East, Thailand and Indonesia, and sales forecast to overtake rotary dressers in two to three years.

The Kinmel Bay operation was founded as Consort Precision Diamond in 1984, specialising in diamond‑encrusted rotary dressers and grinding wheels.

CDT acquired and rebranded the business in 2018; our global headquarters are in New Haven, Indiana.

We are one of only two similar companies in the U.K., supplying sectors that include aerospace, automotive, medical and semiconductors.

Our products are used in Boeing 777 and 787 Dreamliner aircraft, as well as the Airbus A330–A380 range, whose wings are made at the Airbus factory in Broughton, Flintshire.

Managing Director Jeff Wirth said:

“Strategically, appointing the team in Poland was a very important move because it’s the next step in our expansion in Europe.

“Poland’s economy has been transformed in recent years and it’s now a manufacturing powerhouse so this is perfect timing.

“For many years Germany was the engine of Europe and now Poland has taken that mantle.

“Poland is booming and growing. They have a great workforce and a great work ethic and the investment they have made over the past 20 to 30 years has paid off.

“Our operation there is being integrated into the company at a time when we are going to be moving into the new factory which will enable us to triple our production capacity, with new products coming on stream.

“Mariusz will be at the forefront, ensuring that our clients in Poland receive top-notch service and support. His expertise and dedication are key to navigating this phase of growth.

“It’s a really exciting time for CDT – watch this space.”

Continental Diamond Tool Limited (CDT Ltd.), based in Kinmel Bay, Rhyl, U.K., is the European subsidiary of Continental Diamond Tool Corporation, headquartered in New Haven, Indiana, U.S.A. For more than 40 years, CDT Ltd. has been a leader in diamond rotary dresser technology, originally operating as Consort Precision Diamond. Since joining CDT, the company has expanded its product line, delivering high-performance diamond plated grinding wheels and other premium superabrasive products to customers worldwide.

Related links:

https://www.business-live.co.uk/enterprise/north-wales-precision-engineering-firm-31694121

https://www.rhyljournal.co.uk/news/25181361.north-wales-firm-eyes-huge-growth-eastern-europe/

https://www.wales247.co.uk/high-flying-north-wales-engineering-firm-targets-growth-in-eastern-europe

https://businessnewswales.com/north-wales-engineering-firm-targets-growth-in-eastern-europe/

Celebrating Our Apprentices

Apprenticeships at CDT offer hands-on experience, critical skills, and leadership opportunities—more than training, they’re a launchpad for a lifelong career.

CDT Ltd.'s current and former interns (left to right): Corey Lloyd-Jones, Joe Bowles, Stephanie Hughes-Jones, Daniel Hughes-Jones, and Rhys Butler.

Investing in the Future: Celebrating Our Apprentices for National Apprenticeship Week

At Continental Diamond Tool (CDT), we take great pride in nurturing the next generation of engineers through our apprenticeship programs. In celebration of National Apprenticeship Week in the U.K., we’re highlighting the inspiring journeys of five apprentices at our manufacturing center in Wales. Read on to see how these talented individuals have developed their skills, grown within the company, and are shaping the future of engineering.e.”

From Apprentice to Supervisor – Joe Bowles’ Journey

Joe Bowles began his career with Continental Diamond Tool Ltd. in September 2007 as an engineering apprentice. Over the years, his dedication and willingness to learn saw him progress into new roles, gaining invaluable experience along the way. Today, he is the Supervisor of the Grinding Department, where he leads a skilled team and ensures high standards of quality and precision.

Reflecting on his journey, Joe shares:

"From an apprentice 17 years ago to a supervisor, my path has been driven by hard work and the support of a company that values growth, innovation, and investment in people. I look forward to furthering my career with CDT and being part of its bright future."

Joe’s success is a testament to the long-term benefits of apprenticeships, illustrating how they can open doors to leadership and career progression.

Daniel Hughes-Jones – A Key Player in CNC Machining

Daniel joined CDT Ltd. in March 2021, quickly making an impact in the CNC Machining Department. He successfully completed his HNC in Engineering, further strengthening his knowledge and technical expertise. Now, as a key team member, he operates multiple CNC machines and plays an important role in training new apprentices.

"My apprenticeship at CDT provided me with vital knowledge and a developed skill set, and I’m grateful to pass on my knowledge and experiences to the next generation of apprentices." – Daniel Hughes-Jones

Daniel’s ability to mentor new apprentices showcases the value of experienced employees sharing their knowledge, ensuring a strong and skilled workforce for the future.

Corey Lloyd Jones – Building a Strong Foundation

Corey started his apprenticeship with CDT Ltd. in September 2023 and is currently in his second year, working towards his HNC in General Engineering while also completing a Level 3 NVQ. With a strong ambition to learn, Corey is eager to develop his expertise across multiple machines and broaden his engineering knowledge.

"After finishing my apprenticeship, I would like to progress further within the company and learn more skills on more machines. I chose this career path as it looked like a good challenge. I am doing the general engineering HNC course because it opens up a lot of opportunities for me in the future, rather than having just mechanical or electrical HNC." – Corey Lloyd Jones

Corey’s enthusiasm for engineering showcases how apprenticeships provide a solid foundation for career growth, allowing young professionals to tailor their learning to suit their ambitions.

Rhys Butler & Stephanie Hughes-Jones – The Next Generation of Engineers

Rhys Butler and Stephanie Hughes-Jones, Daniel’s younger sister, are the newest members of CDT Ltd.’s apprenticeship program, having joined in September 2024. Though early in their careers, both are already embracing the challenges and opportunities that come with learning on the job.

Rhys shares his thoughts on his apprenticeship so far:

"I've been on my apprenticeship for around seven months now, and I've thoroughly enjoyed it because it has provided hands-on experience, and a deeper understanding of how complex systems come together. The opportunity to apply theoretical knowledge in real-world settings has been both challenging and rewarding. I've gained valuable skills in problem-solving, teamwork, and technical expertise, which have made me more confident in my abilities. Looking ahead, I would love to further develop my expertise in engineering and continue to grow in a role where I can contribute to impactful projects." – Rhys Butler

Stephanie, who was drawn to engineering for its balance of hands-on work and intellectual challenge, shares her experience:

"I chose engineering because I like jobs that are both physically challenging and mentally interesting. My apprenticeship helps me improve my skills as a machinist while giving me chances to keep learning and growing." – Stephanie Hughes-Jones

Their journeys emphasize how apprenticeships provide real-world experience, technical expertise, and career-building opportunities from day one.

Apprenticeships are more than just training—they’re a launchpad for a successful career. They provide a solid foundation for career progression, hands-on experience, and the opportunity to develop vital skills in a fast-paced, innovative environment.

The apprentices above are prime examples of what can be achieved through dedication, hard work, and the right support. From those just starting out to those who have grown into leadership roles, their journeys highlight the value of apprenticeships and the opportunities they create.

👉 Interested in an apprenticeship or know someone who is? CDT Ltd. works closely with Coleg Llandrillo to identify promising candidates for our highly competitive engineering apprenticeship programme. Each year, we offer placements to 2 to 3 students. The next apprenticeships will begin in September 2025. If you’re interested, we encourage you to explore Coleg Llandrillo’s Engineering Programme as the best route to be considered for a future opportunity with us. Learn more about Coleg Llandrillo here: https://www.gllm.ac.uk/

Continental Diamond Tool Limited (CDT Ltd.), based in Kinmel Bay, Rhyl, U.K., is the European subsidiary of Continental Diamond Tool Corporation, headquartered in New Haven, Indiana, U.S.A. For more than 40 years, CDT Ltd. has been a leader in diamond rotary dresser technology, originally operating as Consort Precision Diamond. Since joining CDT, the company has expanded its product line, delivering high-performance diamond plated grinding wheels and other premium superabrasive products to customers worldwide.

Global Growth and Local Jobs Spurred by Cutting Edge Investments at Kinmel Bay Facility

Cllr Nigel Smith visited CDT Ltd. earlier this month to see how £100,000 from the UK Shared Prosperity Fund is driving innovation, growth, and 40 new jobs in North Wales.

Cllr Nigel Smith (left), Conwy Council’s Cabinet Member for Sustainable Economy, visits with Production Manager Justin Hughes (right), showcasing one of the precision-engineered tools made possible by our new cutting-edge equipment, funded in part by the UK Shared Prosperity Fund secured with the help of Conwy Council.

A precision engineering company in North Wales is gearing up for global growth by investing £250,000 in cutting edge equipment.

Recruitment is also underway at Continental Diamond Tool (CDT) in Kinmel Bay as part of an ambitious expansion plan that will create 40 new jobs.

It’s all preparation for a move next year to a 30,000 sq ft factory nearby that’s three times the size of the current premises on the Tir Llwyd Industrial Estate.

Overall, the firm’s Indiana-based American owners, who took it over six years ago, are pumping £4 million into the company to triple production capacity and start making new products.

The niche company specialises in the manufacture of diamond-encrusted rotary dressers and grinding wheels, with tolerances of down to 1,000th of a millimetre in terms of accuracy.

It’s one of only two similar outfits in the UK and supplies a range of manufacturing sectors, including aerospace, automotive, medical and semi-conductors.

The company’s customers include blue chip corporations like Rolls Royce and Tenneco, with more than 60 per cent of the products being exported.

According to the loyal workforce, the investment is the “perfect present” for the company that’s celebrating its 40th anniversary this year.

It was also music to the ears of Cllr Nigel Smith, Conwy Council’s cabinet member for Sustainable Economy, who is one of three councillors who represent Kinmel Bay on the authority.

The council helped CDT secure £100,000 in funding from the UK Shared Prosperity Fund towards the cost of the new equipment.

He came on a visit to see how the money had been spent on “space age kit”, including a high tech machinery centre, lathe and inspection equipment.

Cllr Smith said: “What they do is very impressive, both in terms of the state-of-the-art technology and the high skill employment they provide in Kinmel Bay.

“It’s fantastic that they’re selling their world-leading products to an international market and they have a raft of blue chip customers like Rolls Royce.

“Over the years there has been a good relationship between the company and the council’s business development team and long may that continue.

“We were delighted to be able to help in securing £100,000 towards the cost of these cutting edge machines.

“It’s impressive, top-of-the-range technology and the level of precision they work to is mind-boggling – their tolerances are within microns. It’s engineering of the highest pinnacle.

“With them moving now to larger premises, I’ll be speaking to our team if there is anything more we can do to help them moving forward to help them grow and expand.

“Employment is a key issue in Conwy so have foster and support business where we can to retain our young people.

“It’s good to see the emphasis on training here and the apprenticeships, helped by the fact that they have a very good relationship with the local college.

“It’s always been a great company and there is now a new momentum under the American ownership and it’s very pleasing to see them invest in Kinmel Bay and that will pay dividends.

“The excellent legacy of the original company is now being turbo-charged by the Americans.

“It’s a company with ambition and it’s plain to see how committed the team are here – everybody has a good work ethic and it bodes very well for the future.”

Cllr Smith’s visit was hosted by Production Manager Justin Hughes, whose father was one of the founders of the original company, Peter Hughes.

Justin said: “In this latest investment we have spent £250,000 on the three machines and it’s well in excess of £1 million just on new equipment in the last two or three years.

“We’re very grateful to Conwy Council for their help in facilitating the £100,000 that’s come from the UK Shared Prosperity fund. It’s made a massive difference because it enables us to employ the people to use those machines.

“The skill required by the people we have to do that is of the highest order and is just as important as the machine.

“Training and developing those people is just as key as our processes and our high precision machinery so working with the engineering centre at the local college is a big help.

“I am immensely proud of the company’s legacy and the way things are moving forward. It’s in my blood, this company.

“These are really exciting times with the move to the larger premises which will enable us to have new product lines.

“Continental Diamond Tool are the third biggest superabrasives supplier in the USA and they are looking to become the biggest.

“The American side of the business is growing at a rate of 30 per cent a year and we are the European arm and they are looking to us to emulate that success over here.

“We are developing a name for ourselves against the big multi-national household names and we are becoming one of those names.

Finance Manager Michaela Lawton added: “The expansion into the new premises will enable us to increase capacity and the number of products we make so the sky is the limit.

“All this is happening in the year we are celebrating our 40th anniversary and the American side of the company is celebrating its 50th.

“We’ve got a great team of people here and there’s a shared pride in what we’re achieving.

“The expansion will create another 40 jobs and we have started to recruit people because of the skill sets required and the time it takes to train them.

“We’ve had a steady number of new employees joining us, particularly over the last four or five months so we can get all our ducks in a row.

“We make our products to 1,000th of a millimetre in terms of accuracy so we have to conduct the whole operation with the same level of exceptional quality.”

Evaluating and Optimizing Cutting Performance in Grinding Operations

Learn how to evaluate the cutting performance of grinding wheels for industrial applications using data-driven methods for optimizing efficiency.

Grinding wheels are critical tools in many forms of manufacturing for cutting, shaping, and finishing materials. In this blog, we’ll explore the methods for evaluating cutting performance as detailed by CDT Senior Application Engineer Chad Wesner in Episode 9 of The Grinding Chronicles. Whether you’re using CBN grinding wheels, diamond grinding wheels, or conventional abrasive grinding wheels like aluminum oxide or silicon carbide, optimizing cutting performance is essential for staying competitive.

Watch the video or read the article below to learn how to evaluate grinding wheel performance and make data-driven decisions to improve your grinding operations.

The Grinding Chronicles - Episode 9

Cutting Performance: The Key Metrics to Measure

In The Grinding Chronicles, Chad Wesner, Senior Application Engineer at CDT, outlines the structured process our engineers use for evaluating the cutting performance of grinding wheels. This process involves three key steps: collecting data, processing data, and evaluating the results. Each step builds on the next to provide an effective means of comparing the performance of different wheels, whether CBN, diamond, or conventional abrasive.

1. Collecting Data

The first step is collecting the necessary data from the grinding process. For an accurate evaluation of cutting performance, you’ll need to use the following instrumentation:

Power Meter: Attach a power meter to the grinding wheel spindle to measure the power consumed during the grinding process.

Data Acquisition Device (DAQ): The power meter connects to a DAQ, which records the data from the grinding operation.

Digital Signal Processing (DSP): Export the collected data into a DSP system for further analysis.

This data forms the foundation for assessing grinding wheel performance for comparison with different wheel types or other variables.

2. Processing Data

After data collection, the next step is processing the information to obtain two critical metrics: Specific Power and Specific Grinding Energy.

Specific Power: Start by plotting a graph of spindle power vs. time during the grinding process. The power meter collects measurements while grinding the workpiece at various material removal rates. To calculate Net Grinding Power, subtract the idle spindle power from the steady state grinding power. Repeat this process multiple times at different material removal rates, and plot the results to create a graph of specific power.

Specific Grinding Energy: This metric represents the amount of energy required to remove a specific volume of material. Similar to specific power, the spindle power vs. time graph provides the total energy in Joules. To calculate Specific Grinding Energy, divide the total energy by the volume of material removed, yielding a value in Joules per cubic millimeter.

These two metrics allow you to compare the cutting efficiency of different grinding wheels and make informed decisions about which wheel performs best for your application.

3. Evaluating Data

Once the data is processed, the final step is to evaluate the cutting performance of the grinding wheels. By examining the graphs of data for Specific Power and Specific Grinding Energy, you can identify which wheel delivers better performance.

In The Grinding Chronicles video, you can see in our graph that the wheel represented by the blue line had the best cutting performance because it had the lowest power per material removal rate. In the next graph, we can see that the wheel with the lowest Specific Grinding Energy was more free-cutting, indicating greater efficiency and reduced energy consumption during the grinding process.

Taking Your Grinding Operations to the Next Level

Evaluating cutting performance is an essential part of optimizing grinding processes, whether you're using superabrasive grinding wheels or conventional abrasive wheels. By measuring Specific Power and Specific Grinding Energy, you can compare wheel performance, make informed decisions, and fine-tune your grinding operations for better efficiency and quality.

At Continental Diamond Tool, we have a team of application engineers that specialize in helping our customers with this type of analysis. If you're looking for more help with common grinding problems and their remedies, or need assistance optimizing your cutting performance, contact CDT’s engineering team at TheGrindingChronicles@cdtusa.net.

By following these evaluation methods and choosing the appropriate grinding wheel for your material, you can achieve superior cutting performance and enhance the efficiency of your grinding process.

Emphasis on Outstanding Customer Service at Continental Diamond Tool

At Continental Diamond Tool, customer service isn’t just a department—it’s a priority. Check out our latest blog that covers the various ways our sales and customer service teams collaborate to deliver personalized solutions that meet our customers’ needs.

At Continental Diamond Tool (CDT), customer service isn’t just a department—it’s the core of our entire operation. From the moment a customer reaches out with an inquiry to the final delivery of the product, CDT ensures that every interaction reflects our commitment to quality, collaboration, and satisfaction. Our expert sales team, fast response times, and innovative technical solutions come together to create an outstanding customer experience at every step. Watch the video or read the article below to learn more.

Putting the Customer First

"Everything we do is centered around ensuring that the customer comes first," says Erik Van Meter, Senior Product Manager of Conventional Abrasives at CDT. This philosophy shapes the day-to-day operations of every department. Whether it’s processing quotes, collaborating with engineers, or ensuring timely delivery, CDT’s entire focus is on taking care of the customer.

At CDT, we understand that every customer has unique needs. Whether they are an aerospace company seeking specialized grinding tools or a medical device manufacturer looking for precision and reliability, we treat each client with the same level of attention and dedication. We take pride in offering high performance grinding solutions that are not only effective but also tailored to their specific challenges

Simplifying the Process

A seamless customer experience begins with a streamlined process. According to Jeff Gongaware, CDT’s Customer Service Manager, "The process of getting a quote from CDT couldn’t be any easier." At CDT, customers can inquire via phone, email, or through our website, making it convenient and flexible to begin the process. Once a quote is approved, we provide an acknowledgment within 24 hours, ensuring that communication is prompt and clear.

This quick turnaround is a point of pride for CDT. "One of the things I always hear at CDT is how fast we get our quotes back to our customers compared to our competitors," says Matt Harnish, one of CDT’s dedicated sales representatives. In today’s fast-paced manufacturing environment, time is of the essence, and CDT’s ability to provide quick, accurate quotes sets us apart from the competition and builds strong relationships with our customers.

Real-Time Solutions for Real-World GRINDING Challenges

Our commitment to customer satisfaction goes beyond providing fast quotes on high-quality tools — we also work hand-in-hand with our customers to develop solutions that address their specific needs. As Blu Conrad, CDT’s Application Engineer, explains, "In our facility, we have our own grinding lab with machines dedicated to R&D and prototyping." This allows customers to test out solutions and adjust their parameters without downtime, all with CDT’s extensive expertise to guide the process.

In addition to offering product testing at our facility, CDT provides on-site support for customers facing unique challenges. "If they have a specific challenge that they can't solve on their own, an application engineer can go to their facility and spend whatever time is needed to work directly with their operators and engineers," says Blu. This personal approach ensures that CDT’s customers not only receive the tools they need but also the support to optimize those tools in their own production environments.

A Collaborative Approach to GRINDING WHEEL DESIGN

At CDT, we believe that teamwork makes all the difference. "At CDT, there are no silos," Erik notes. "Each department within the organization works together to ensure that the customer needs are met." This collaborative spirit ensures that whether a customer is interacting with sales, engineering, or production, they receive the same level of care and attention throughout their journey with CDT.

This culture of collaboration is key to maintaining fast response times, high-quality service, and long-lasting relationships. From quoting to production to delivery and support, each department at CDT works in unison to ensure that every order is fulfilled efficiently and to the highest standards. This teamwork fosters a work environment where our employees are empowered to share ideas, solve problems, and take pride in our customers’ success.

GRINDING Expertise That Makes a Difference

Behind every solution is a team of experts who bring years of experience to the table. Whether it’s solving complex grinding issues or fine-tuning product specifications, CDT’s team has the knowledge and expertise to help customers overcome any challenge. "With my 23 years of experience in grinding, I can help give customers a new perspective on facing their challenges," Blu shares. His expertise, combined with the know-how of CDT’s wider team, ensures that our customers are never alone in their search for the right solution.

Jeff adds, "What it takes to be successful in customer service at CDT is a positive attitude, product knowledge, and some problem-solving." These qualities are essential in guiding customers through the entire process, from initial inquiries to product delivery. CDT’s team not only knows the right questions to ask but is also skilled at offering insights and recommendations that help customers arrive at the best solution for their needs.

Personalized, Efficient Service

One of the key benefits of working with CDT is our personalized approach. "Every one of our tools is engraved with a specific W number," Jeff explains. "You can call us with that information, and we can go back and pull all the manufacturing specifications from the last time we made it." This system allows us to quickly and efficiently handle reorder requests, ensuring that customers receive the same high-quality tools they’ve come to rely on.

At CDT, we recognize that our customers are not just looking for products; they are looking for solutions that will help them succeed long term. By focusing on quick response times, personalized service, and expert problem-solving, we deliver not just tools but peace of mind.

Diverse Customer Base, Unique Solutions

Working with a diverse customer base presents unique challenges and opportunities. For Matt, the variety of customers makes the job exciting. "What I love about working at CDT is the wide range of customers that I get to deal with on a day-to-day basis. I’ve got boat manufacturers, medical companies, and those crafting airplane engines," Matt says. As a custom solutions provider of superabrasive tools, every product is unique and every design is tailored to meet the specific needs of our customers.

Whether we are working with customers in the medical field or in aerospace, we take the time to understand their individual needs. This tailored approach ensures that each customer gets exactly what they need to thrive in their respective industries.

Above and Beyond

At Continental Diamond Tool, our commitment to customer service is evident in everything we do. From the first inquiry to ongoing support, we prioritize our customers’ success through collaboration, innovation, and expert guidance. As we continue to grow and expand, we remain focused on delivering the exceptional service and high-quality products that our customers have come to expect.

By working with CDT, customers gain access not only to cutting-edge tools but also to a team of dedicated professionals who are always ready to go the extra mile. Contact our sales team today at cdtusa.net/contact.

CDT Ltd. Unveils £4m Expansion Creating 40 New Jobs

Continental Diamond Tool has announced a £4 million expansion plan at its North Wales operation that will double the workforce there by creating 40 new jobs and triple production.

From left: CDT Ltd. Managing Director Jeff Wirth, Finance Manager Michaela Lawton, General Manager Troy Giacherio, Production Manager Justin Hughes, President of Sales Shane Vardaman, and Director Nick Viggiano stand outside the 30,000 sq. ft. factory that the North Wales operation will soon be occupying.

A fast-growing precision engineering firm has announced a £4 million expansion plan that will double the workforce at its North Wales operation by creating 40 new jobs and triple production.

The investment by the American owners of Continental Diamond Tool (CDT) will include moving to a 30,000 sq ft factory that’s nearly three times the size of its current premises in Kinmel Bay and is less than half a mile away on the Tir Llwyd Industrial Estate.

The move is being hailed by staff as the “perfect birthday present” for the North Wales operation which is celebrating its 40th anniversary this year, having been founded as Consort Precision Diamond in 1984, specialising in the manufacture of diamond-encrusted rotary dressers and grinding wheels.

The niche outfit – still one of only two similar companies in the UK – supplies a range of manufacturing sectors, including aerospace, automotive, medical and semi-conductors.

Its products are used in Boeing 777 and 787 Dreamliner aircraft, as well as the Airbus range A330-A380 whose wings are made at the giant Airbus factory in Broughton in Flintshire.

The firm was taken over and rebranded in 2018 by CDT which has its headquarters in New Haven, Indiana.