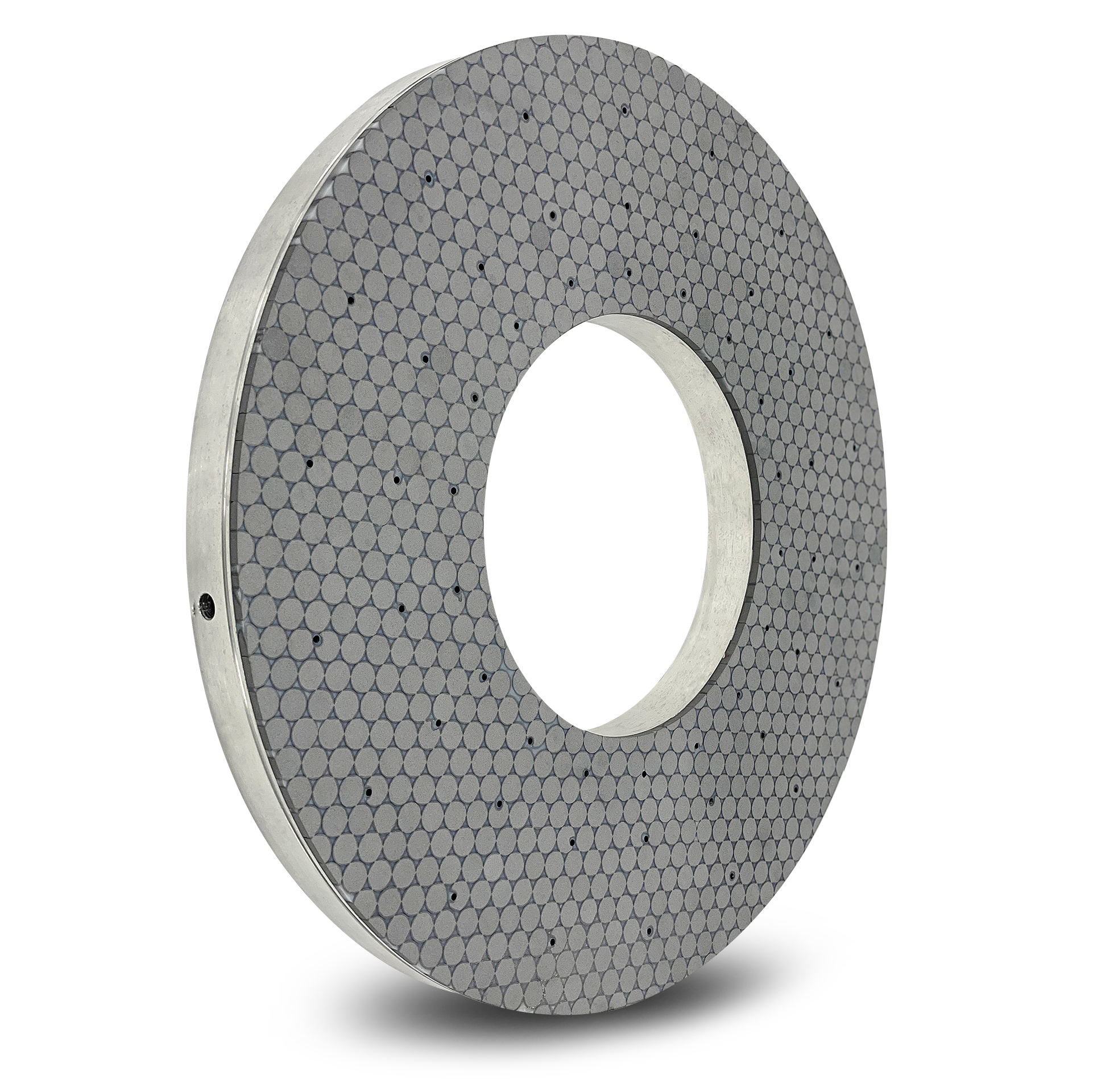

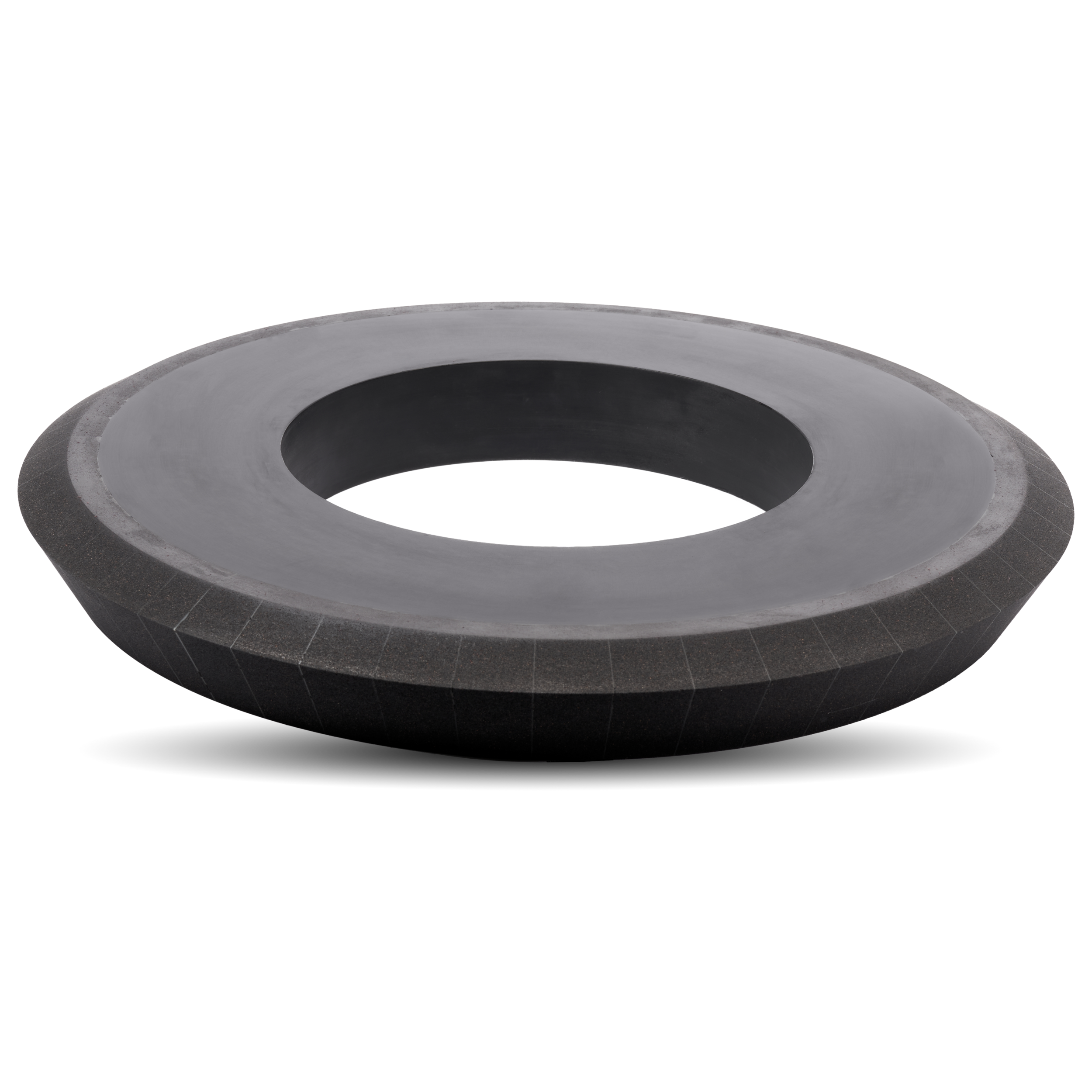

VITRIFIED DIAMOND AND CBN GRINDING WHEELS

For High Efficiency, Lights Out, and Fine Grinding

• Improved Cycle Times

• Lights Out Operation

• Efficient Heat Removal

ABOUT VITRIFIED DIAMOND GRINDING WHEELS

Vitrified Diamond and CBN grinding wheels combine the hardest known Superabrasives, held mechanically and chemically in glass or ceramic bonds, to form some of the most efficient grinding products available on the market. Vitrified grinding wheels’ compositions and structures are engineered with varying concentrations, porosity levels, and bond hardness to provide optimal performance specific to each customer's grinding process.

VIPER Vitrified Bond

The Hardest Materials just became easy WITH THIS DIAMOND GRINDING WHEEL

PROVEN ADVANTAGES INCLUDE > Increased throughput > Improved surface finish > Maintains material structural integrity > Automated grinding > Cost savings!

Have you struggled to grind hard materials such as Silicon Carbide, Aluminum Oxide, Glass, Carbide, and others? With these substances, it has always been hard to improve cycle times and reduce chipping and scrap until now. Our VIPER Bond Technology combines high bond strength with optimal porosity levels. The result? Customers have reported a substantial improvements to the grinding process and significant cost savings.

Vitrified Grinding Wheels with VIPER™ Bond Technology have been shown to reduce cycle times by 70% when compared with conventional resin bond grinding processes. Cycle times were reduced by 30% or more when compared with traditional vitrified grinding products.

Abrasive Utilization

Although Diamond and CBN (Cubic Boron Nitride) are both superabrasives, the use of Diamond and CBN varies, depending upon the materials to be ground.

By INDUSTRY

Common industry

applications include:

Cam & Crank

PCD/PCBN

Mold & Dies

Turbine

Medical Instruments

Ceramics

By Materials

Vitrified Diamond grinding wheels are ideal for production grinding applications of super-hard materials such as:

PCD/PCBN

Diamond and Diamond-like Materials

Carbide

Ceramics

Composites

Abrasives

Vitrified grinding wheels made with CBN, with their hardness and high thermal conductivity, are perfect for grinding:

High-speed tool steels

Tool or Mold & Die steel

Hardened carbon steels

Hardened stainless steels

Alloy steels

Aerospace alloys

Chilled Cast Iron

Powdered Metal

By MACHINE

CDT frequently supplies vitrified grinding wheels in diamond or cbn for machines by the following original equipment manufacturers (OEMs):

ANCA

EWAG

Coborn

Campbell

DMG Mori

Gleason

Junker

Landis

LapMaster

Makino

Studer

USACH

Walter

Frequently Asked Questions

-

CDT follows the rules stated in the American National Standards Institute Safety (ANSI B7.1) Requirements that ensure operator safety and prevent accidents. Here are some safety tips and precautions that you must follow:

Wear protective equipment like safety glasses, hearing protection, gloves, and protective clothing.

Inspect for any cracks, damage, or defects.

Follow proper procedures for mounting the CBN or Diamond Vitrified grinding wheel onto the machine spindle.

Ensure that the wheel is securely fastened and aligned.

Use coolant or lubrication to control heat generation during grinding.

Maintain a safe distance from the grinding area while the machine is in operation.

For more information, see our Safety Guide for Vitrified wheel users.

-

Vitrified bond grinding wheels can be used across a range of industries including

Cam and Crank Manufacturing

Automotive

PCD/PCBN

Mold and die Production

Turbine Manufacturing

Medical Instrument Production

Ceramics and Advanced Materials

Oil and Gas

Automated Production

Grinding wheels cater to diverse manufacturing needs. If you are searching for something specific, get in touch at info@cdtusa.net.

-

All CDT grinding wheels are custom manufactured based on our customer’s specific grinding parameters. As a custom product, pricing is determined by the particular grinding wheel you need. To request a quote, reach out to our sales team at 800-443-6629. Get quick, accurate, and competitive pricing today.

-

CBN and Diamond wheels are highly durable and essential tools for cutting, grinding, and shaping hard materials like ceramics, metals, or composites. Follow these guidelines to maintain the performance and longevity of your grinding wheel:

Cleaning: Properly placed coolant and pressure ensure proper cleaning and removal of grinding swarf from the grinding wheel structure. Depending on the application/material being ground, special considerations may be needed (contact CDT for applications support).

Truing & Dressing: Periodically dress the wheel to maintain its cutting surface and shape to ensure its effectiveness. This process exposes new, sharp diamond particles and maintains a true profile. Our dressing specialists can recommend the best dressing tool for your process.

Cooling: Adequate cooling is essential during operation to prevent overheating. Use coolants with proper nozzle placement to lubricate and cool the wheel during use, especially in high-speed applications.

Storage: Store diamond wheels in a dry and secure place to prevent contamination or damage. Avoid exposure to moisture or extreme temperatures that might affect the wheel's integrity.

Inspection: Regularly inspect diamond wheels for any signs of damage, wear, or unevenness. Replace worn-out or damaged wheels promptly to prevent safety hazards and maintain quality results. Never use a wheel that has been subject to crash or other mishap that could affect product integrity (sometimes they can be returned and recertified for use).

Proper Usage: Check with one of our application engineers for the correct usage of Diamond & CBN wheels. Avoid using excessive pressure or inappropriate speeds that can cause damage. Never operate a grinding wheel above the speed that it is marked for.

Safety Measures: Always use appropriate safety gear when working with diamond wheels, including goggles, gloves, and face masks, as they can generate fine, airborne particles during operation.

Remember, specific procedures might vary depending on the type and purpose of the diamond wheel. Always follow the Vitrified Diamond & CBN grinding wheel manufacturer guidelines for care and maintenance recommendations.

-

No. Because each wheel is custom engineered for the application, we do not carry wheels in stock except for specific customers under agreement. Each CDT grinding wheel is custom manufactured for optimized performance based on a wide array of variables such as material of the workpiece, grinding machine, dressing method, volume of parts, coolant type, stock removal, and current grinding process. We work quickly, and with care, to ensure a quality product is delivered promptly, and to precise specifications. Please contact our customer support for estimated lead times and a personalized quote.