News and Resources

Browse by Category

Browse by Product

- All Dressing Products

- All Grinding Products

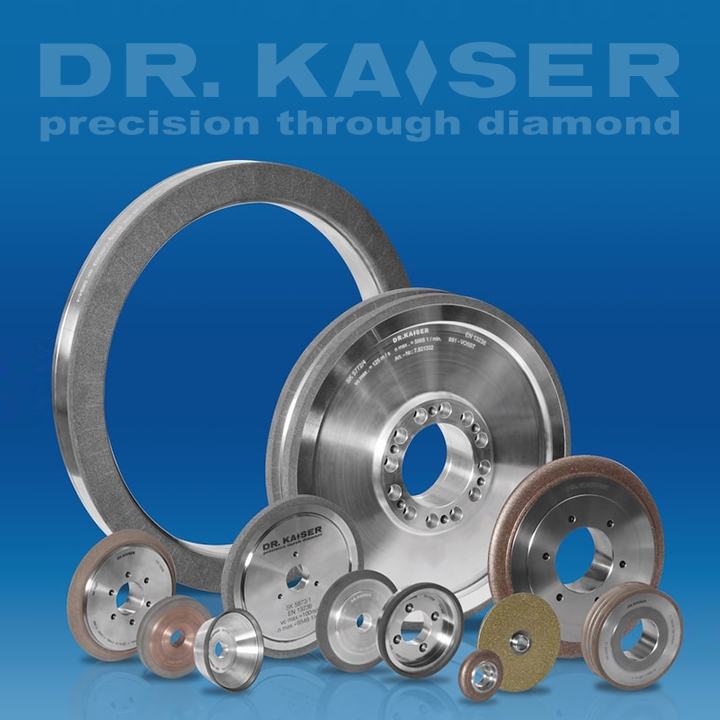

- CBN-Diamond Superabrasives

- Conventional Abrasives

- Diamond Lapping Compounds

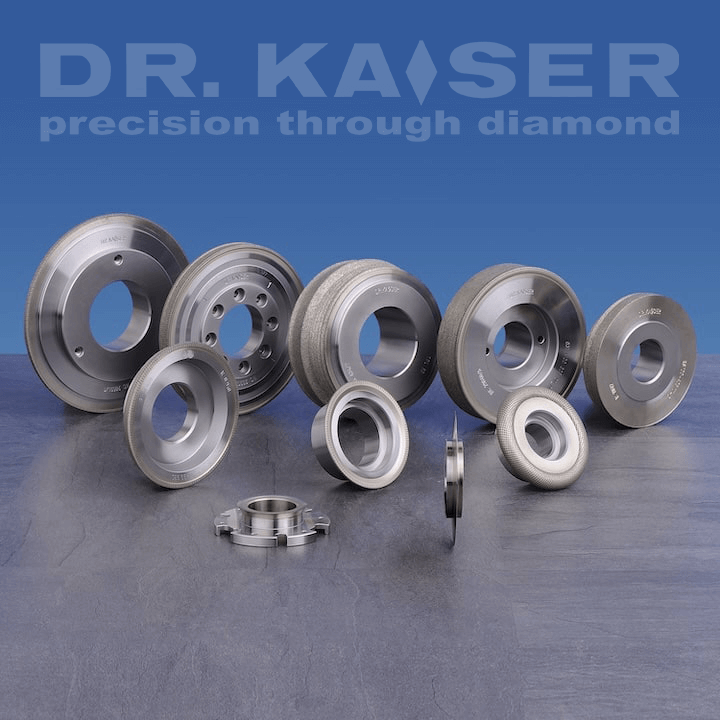

- Diamond Rotary Dressers

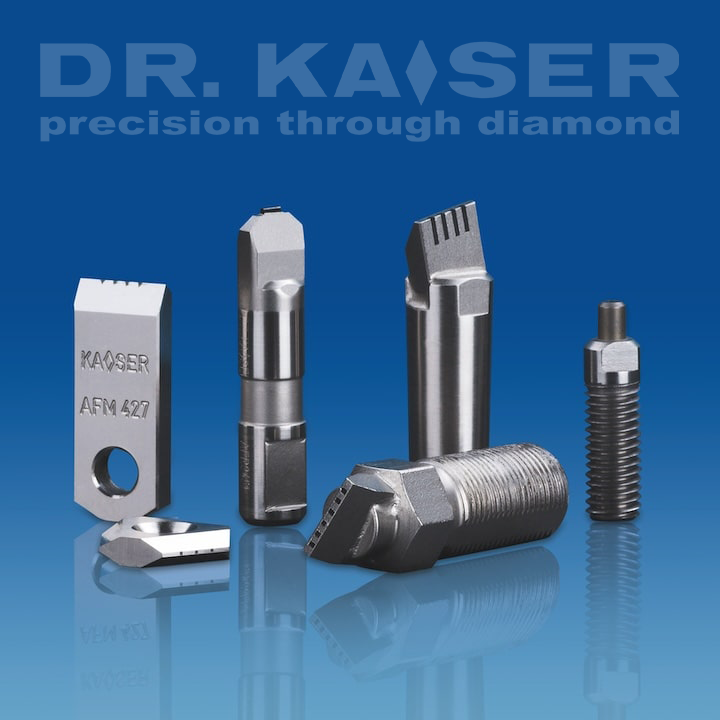

- Diamond Stationary Dressers

- Hybrid Bond Grinding Tools

- Metal Bond Grinding Tools

- Plated Grinding Tools

- Resin Bond Grinding Tools

- Vitrified Bond Grinding Tools

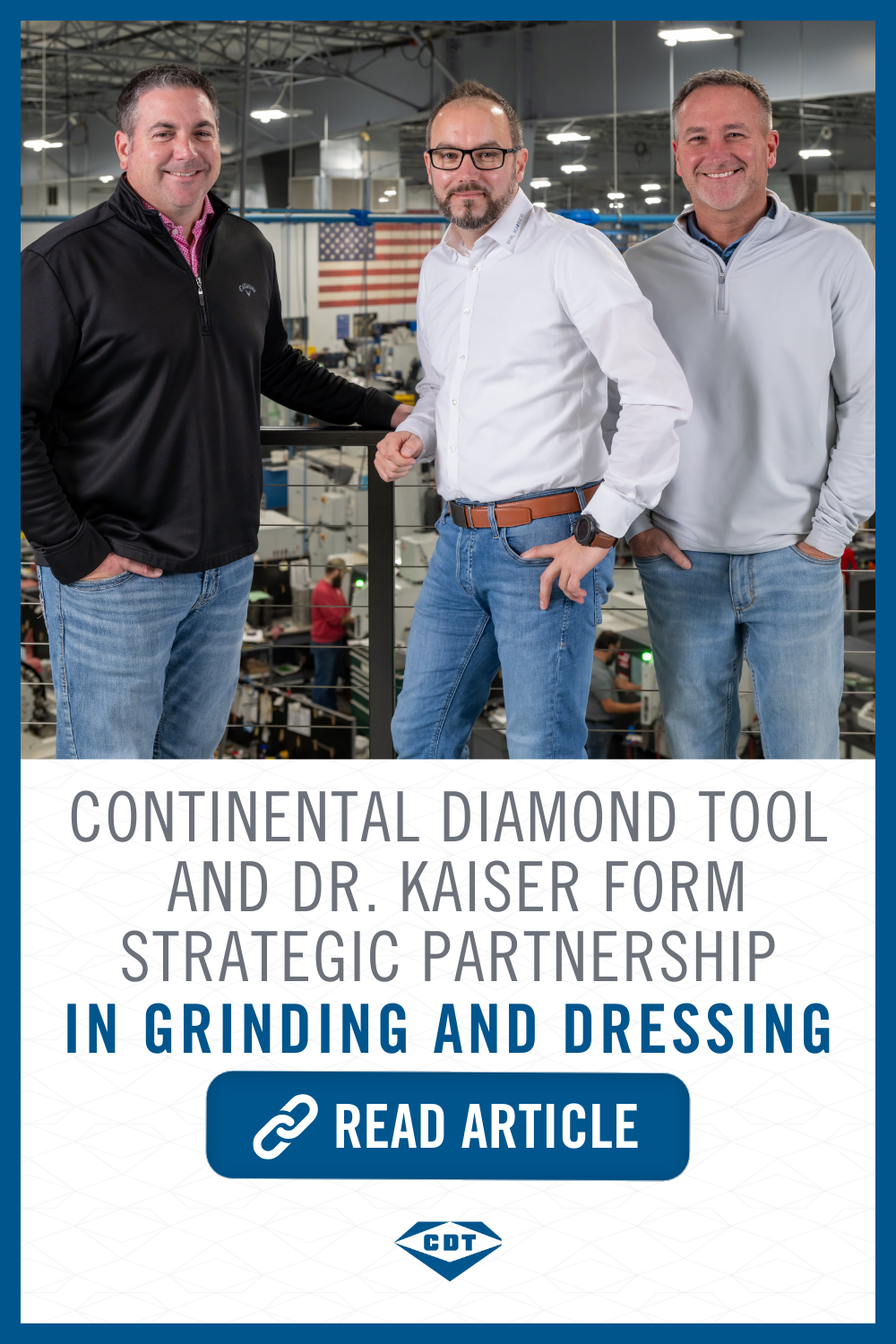

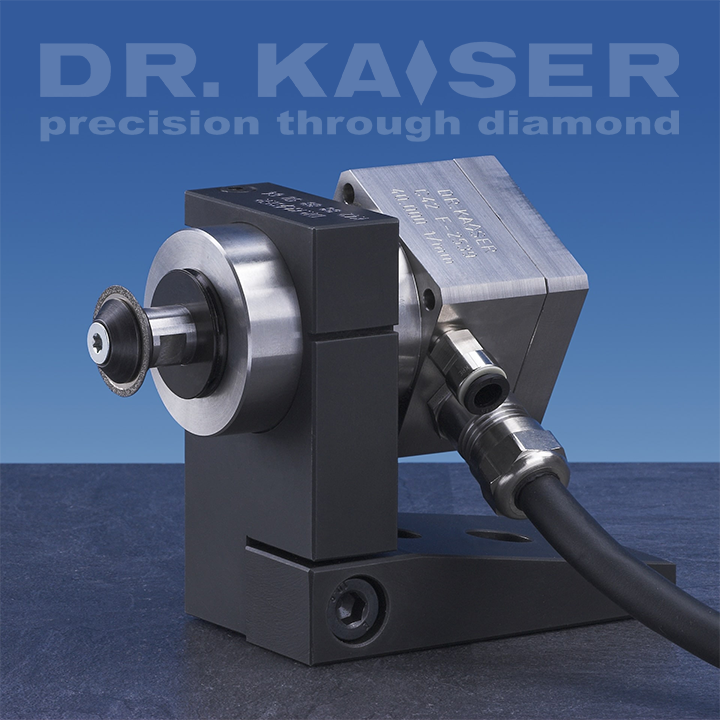

Continental Diamond Tool and DR. KAISER Form Strategic Partnership in Grinding and Dressing

CDT now represents DR. KAISER in North America, expanding access and service for their grinding, dressing, spindle, and wear protection products.

Continental Diamond Tool (CDT) and DR. KAISER DIAMANTWERKZEUGE GmbH & Co. KG are pleased to announce a strategic partnership between these two long-standing leaders in grinding and dressing technology. Under the agreement, effective Feb. 11, 2026, Continental Diamond Tool will represent DR. KAISER products throughout North America, including the United States, Canada and Mexico. After 30 successful years of representation, S.L. Munson is now supporting a seamless transition for customers to CDT as the new DR. KAISER representative. The new strategic agreement includes that DR. KAISER will offer CDT’s diamond and CBN grinding wheels across Central Europe and Turkey to complement the existing portfolio.

Watch the video below or read on for details.

A Unified Approach to Grinding and Dressing

The partnership between Continental Diamond Tool (CDT) and DR. KAISER combines world-class superabrasive technology with responsive, application-driven support for grinding operations worldwide. Both companies trace their roots to the 1970s and have grown alongside the adoption of industrial diamond and CBN abrasives in modern manufacturing. Today, each has evolved into a solutions provider—recognizing that grinding wheels, dressers, and related components must work together to deliver superior performance.

Together, CDT and DR. KAISER bring complementary strengths. DR. KAISER offers technologies CDT does not manufacture, including spindle systems, wear protection, and specialized types of rotary dressers. CDT manufactures custom diamond and CBN grinding wheels with larger diameters, complex configurations, and a broad range of bond types and grit sizes. The result is a more integrated solution for advanced manufacturers, including:

Grinding wheels and rotary dressers engineered to your process

Expanded options in grinding, dressing, spindle, and wear-protection technologies

Application support focused on data-driven results

What Changes in North America

As of February 11, 2026, DR. KAISER has transitioned North American product sales to Continental Diamond Tool. CDT now represents DR. KAISER’s full product portfolio across the United States, Canada, and Mexico, supported by CDT’s established network of sales representatives and application engineers.

For customers, this means DR. KAISER’s German-manufactured technology is paired with CDT’s process knowledge, fast communication, and local technical support. CDT sales engineers work closely with customers to align grinding performance goals, dressing strategies, and overall process outcomes when specifying DR. KAISER solutions.

“We look forward to welcoming DR. KAISER customers to CDT,” said Shane Vardaman, Chief Commercial Officer at Continental Diamond Tool. “Our focus is on operational continuity, responsive technical support, and ensuring customers experience a seamless transition in service.”

Expanded Capabilities in Central Europe and Turkey

Through the partnership, DR. KAISER will offer CDT’s diamond and CBN grinding wheels throughout Central Europe and Türkiye. This expands access to CDT’s plated and hybrid bond grinding wheels with large diameters as well as our vitrified bond double disk grinding wheels.

Together, the companies provide a shared platform to better support manufacturers working with demanding materials and tight tolerances.

“This partnership expands how we can serve customers,” said Christoph Müller, Head of Sales at DR. KAISER. “Working with CDT allows us to combine complementary strengths and offer more extensive grinding solutions on a global scale.”

Growing Through Shared Values and Vision

This alliance offers customers a true system-provider model—combining proven technology with expert service. Both organizations bring decades of experience and a common commitment to:

Precision and quality

Custom innovation

A systems-based approach

Responsive technical support

“This is more than a distribution change—it’s a long-term partnership built around how advanced grinding is evolving,” said Nick Viggiano, President at Continental Diamond Tool. “Together with DR. KAISER, we’re focused on delivering integrated solutions that help manufacturers meet increasingly complex requirements in manufacturing.”

For more information about DR. KAISER products in North America or CDT’s global capabilities, visit CDTUSA.net or DRKAISER.de. Contact your sales representative to get started.

Continental Diamond Tool designs, develops, and distributes custom grinding and dressing technology for advanced manufacturing worldwide. Founded in 1973, CDT supports precision manufacturing across industries such as aerospace, automotive, cutting tools, medical, and energy. The company operates manufacturing facilities in the United States and the United Kingdom and is known for innovation in superabrasive solutions and expert application support.

DR. KAISER DIAMANTWERKZEUGE GmbH & Co. KG built its reputation as a leader in diamond rotary dressers before expanding into grinding wheels, spindle systems, stationary dressing, and wear-resistant components. Founded in 1977 and headquartered in Germany, the company supports high-performance grinding applications worldwide and is recognized as a system provider, delivering innovation and expertise across dressing, grinding, spindle, and application technologies, including the DR. KAISER dressing and grinding app.

CDT Opens 2026 Ready for Growth

CDT President Nick Viggiano reflects on 2025 investments and shares how Continental Diamond Tool is positioned to support customers in 2026.

As we begin 2026, Continental Diamond Tool enters the new year with momentum, readiness, and a clear focus on partnership. The past year was one of meaningful investment. We’ve been deliberate in our growth to ensure our customers remain supported as the global manufacturing landscape becomes more complex.

In this video message and article below, CDT President Nick Viggiano reflects on the milestones achieved in 2025 and outlines how those efforts have positioned CDT—and our partners—for continued success in the year ahead.

Watch the video or read the article below to see the President’s Message: Welcoming 2026

Supporting Our Partners Today and Tomorrow

Since 1973, Continental Diamond Tool has grown alongside the customers and industries we serve. Entering the superabrasives industry early in its commercial development, our growth has always been driven by relationships: listening closely and responding quickly with innovative solutions that perform in real production environments.

In 2025, this approach guided some of the most significant investments in CDT’s history. Against a backdrop of shifting tariffs, geopolitical unrest, and increasing supply chain uncertainty, we have taken deliberate steps to ensure our customers can rely on us without interruption.

2025: Strengthening Capacity and Capability

Throughout 2025, CDT focused on expanding our ability to serve customers in North America and Europe with speed, consistency, and confidence.

Facility Expansion in the United States

We completed the fit-up and moved into our 72,000-square-foot expansion in New Haven, Indiana, increasing our total footprint to 200,000 square feet. Speaking to the expansion, Nick explains, “This couldn’t come at a better time as we are seeing the reshoring of manufacturing here in the U.S., which has put us in a great position to handle new and existing customer growth in North America.”

New Facility in Wales

In Q3 of 2025, our team in Wales transitioned into a larger, newly renovated facility. The team has adapted quickly, supporting new customer growth across Europe while expanding our global manufacturing and application support capabilities.

Supply Chain Resilience

To protect our customers from global uncertainty, CDT has made several proactive investments. In the video, Nick explains, “With the uncertainty of tariffs and government posturing between countries around the world, we decided to put an 18-month supply of diamond in our vault to ensure that we will be able to deliver no matter the global climate.”

Continued Investment in People

Emphasizing what differentiates CDT, Nick adds, “What continues to set us apart is our customer service and application team that supports our sales team. While our competition continues to eliminate these positions, we continue to add these valuable members.” CDT remains committed to investing in these roles to help customers optimize processes, innovate solutions, and fully realize the value of our products.

What We Reinforced Along the Way

The lessons from 2025 reaffirmed what has long set CDT apart:

Service Matters – Strong application and customer support remain central to helping customers fully realize the value of our products.

Preparation Enables Confidence – Investing ahead of demand allows us to support growth without compromise, even in the face of uncertainty.

Partnership Drives Progress – The best solutions are built through collaboration, when customers and suppliers throughout the value chain work together toward a shared goal.

2026: Moving Ahead with Clarity and Focus

As we head into 2026, CDT is excited about new partnerships that will further expand our ability to support advanced grinding applications. These collaborations are being developed with a clear goal in mind: helping our customers succeed as requirements become more complex and expectations continue to rise.

Quality, service, and partnership remain central to how we approach our work and our relationships. These principles help guide our decisions and shape where we invest.

Closing his message, Nick expressed his appreciation: “To our customers around the world, thank you for choosing CDT as your trusted partner. Your confidence in our team inspires us to continue adapting and growing to deliver solutions that support your success. You are the reason we exist.”

Stay Connected with CDT

Discover CDT’s latest product developments, company news, and educational resources through our blog, videos, and LinkedIn presence. We’re committed to supporting the grinding community with solutions that move precision manufacturing forward.

Why This Grinding Demo Caught Toolmakers’ Attention

CDT tests EVO Hybrid Bond on the Walter Mini Plus—see what the results reveal about performance in carbide tool production.

In cutting tool manufacturing, productivity gains often hinge on one critical factor: wheel performance. CDT’s EVO™ Hybrid Bond grinding wheels offer distinct advantages in demanding carbide grinding applications, but the real story is how they behave in high-accuracy tool development work. To see how these wheels perform on United Grinding’s Walter Helitronic Mini Plus, watch the video demonstration below, or read on for a deeper look at what makes this hybrid bond technology such a powerful solution for tool manufacturers.

Watch the video or read the article below to see why this grinding demo caught toolmakers’ attention.

Hybrid Bond Performance on the Walter Helitronic Mini Plus

Shops faced with growing demands for speed and precision rely on grinding tools that can keep up, and that’s been the focus of CDT’s new product development with our EVO Hybrid Bond line. Harrison Sheldon, R&D Application Engineer at CDT, recently demonstrated this next-gen bond technology on the Walter Helitronic Mini Plus, showcasing the wheel’s capability in flute and tool grinding.

“We’re pretty excited about the new offerings from CDT, including our high-performance flute grinding and tool grinding products,” Harrison says. “We have our new EVO products on the machine demonstrating their great grinding abilities.”

For operations where stability, burn control, and form accuracy directly impact tool quality and cycle time, these EVO diamond wheels are a game changer. The demonstration highlighted several benefits a custom hybrid bond wheel can bring to cutting tool production.

Why Hybrid Bond Wheels Excel in Tool Grinding

EVO Hybrid Bond diamond grinding wheels combine the best characteristics of resin and metal bonds to create a wheel that is both fast-cutting and dimensionally stable. This makes them particularly well suited for flute grinding, secondary relief grinding, periphery, and other geometries where accuracy and wheel wear must stay tightly controlled.

1. Aggressive yet Controlled Cutting Action

EVO’s specially formulated bond allows superabrasive grains to cut freely while maintaining structural support. This balance delivers:

Higher feed rates

Lower grinding forces

Reduced cycle times

This is especially valuable in operations where standard resin bonds would wear too quickly or require frequent dressing.

2. Improved Thermal Performance

Tool steels, carbide blanks, and increasingly complex tool geometries place significant heat load into the grinding zone. The EVO wheel system with its copper core is built to dissipate heat efficiently, helping reduce:

Risk of burning

Micro-cracking

Thermal distortion

“These wheels really show strong, stable performance even at more aggressive speeds and feeds,” Harrison notes. “That’s a big advantage for customers trying to push productivity while keeping their tools cool and consistent.”

3. Extended Tool Life and Fewer Changeovers

Hybrid Bond diamond wheels maintain form longer than standard resin-bond wheels. This translates into:

Longer dressing intervals

Less wheel wear

More consistent part geometry

Whether this wheel is running in tool shops with high-mix, low-volume production or operations grinding carbide round tools around the clock, these improvements mean increased uptime and reduced consumable cost.

4. Ideal for High-Precision Machines

The Walter Helitronic Mini Plus is built for accuracy, and the performance of CDT’s Hybrid Bond diamond grinding wheels complements its capabilities. The wheel’s stability ensures that both form accuracy and flute consistency remain controlled throughout long runs or high-removal-rate passes.

best Applications for Hybrid Bond diamond grinding wheels

EVO Hybrid Bond diamond grinding wheels are a strong fit for a range of carbide and HSS tool manufacturing applications, including:

Flute grinding

Primary and secondary relief grinding

Step tool grinding

Chamfering and point thinning

End mill and drill production

Their ability to maintain shape while cutting aggressively makes them particularly effective in flute grinding where high-precision is essential for ultimate tool performance.

In addition to round tools, CDT also offers EVO Hybrid Bond periphery diamond wheels for carbide insert grinding, where consistent form retention and thermal stability are especially critical.

Top-of-the-line Diamond Grinding Wheels for All Major Tool Grinders

This demonstration was filmed at United Grinding’s Precision Summit last summer, where CDT showcased how its wheels perform on industry-leading equipment. CDT customizes grinding wheel solutions for all major machine OEMs—including United Grinding—to ensure customers get reliable, real-world performance across their production environments.

“We appreciate having the opportunity to test these wheels on the Walter Mini Plus. The results really show what this technology can do for tool manufacturers,” Harrison says. “It’s exciting to bring new products like EVO to the market with this level of performance.”

How to Get Hybrid Bond Grinding Wheels for Your Walter Mini Plus

If you work in cutting tool manufacturing and would like to explore EVO Hybrid Bond diamond grinding wheels for your flute grinding, relief grinding, or insert production process, reach out to our sales team or request a quote at cdtusa.net/hybrid-bond.

If you operate in another industry and need a specialized grinding solution, CDT’s product engineering team can work with you to develop a custom hybrid bond formulation tailored to your material, machine platform, and performance goals. Contact us to get the conversation started.

Engineering for Tomorrow, Today

Hear from engineers about what it's like to work at CDT — the challenges, growth opportunities, and mentorship available—as we build the best engineering team in the grinding industry.

Continental Diamond Tool (CDT) is a custom engineering firm that designs, develops, and manufactures superabrasive grinding wheels and dressing tools for global precision manufacturing. From aerospace and automotive to energy and medical technology, CDT products are shaping advancements around the world. And behind every tool is a team of engineers — from product engineers and process engineers to R&D and application specialists — driven to meet the evolving needs of customers who are continuously pushing what’s possible in manufacturing.

Watch the video or read the article below to see how CDT is building an engineering team for tomorrow, today.

Adapting for the Future

At CDT, every project begins with a customer challenge. When our customers develop technology using increasingly advanced materials and more sophisticated equipment, we adapt by designing the tools that make their success achievable. It’s an environment where problem-solving, creativity, and technical expertise come together to turn complex engineering challenges into real-world solutions.

Growing Through Experience

At CDT, our future focus starts with people. We’re building an engineering team that can adapt, lead, and solve for what’s next in manufacturing. For new product engineers like Daniel Montez, joining CDT has meant joining a team that knows collaboration sparks innovation.

“The knowledge here is unmatched,” says Daniel. “You have people from all different backgrounds coming together in one place — collectively decades worth of experience coming together to make the best product that they can.”

That diversity of knowledge defines CDT’s culture. It’s a place where mentorship, career growth, and continuous learning are built into the workflow. Here, every engineer plays a role in advancing precision manufacturing.

“At CDT, we’re passionate about building the best technical team in the industry — a team defined by excellence in quality and service,” says Jack Shindle, VP of Engineering, Research, and Development. “We’ve created an environment where knowledge sharing happens naturally, and where every engineer has the opportunity to grow and make an impact.”

For Daniel, that support system is what makes CDT stand out.

“I’m always talking to the head engineer in my department,” he explains. “He sits right across from me in the office and is always ready to show me something new, give me a challenge, or walk me through something. That kind of support is what so many engineers need.”

The result is a workplace where engineers are encouraged to think differently, share ideas, and grow through hands-on experience. Every new project brings opportunities to learn, whether it’s optimizing a wheel for a new grinding process, experimenting with a new dressing method, or supporting a customer’s move into next-generation materials.

Scaling Leadership

At CDT, growth isn’t limited to technology: it extends to our people. Service is at the heart of everything we do, and delivering the best results for our customers requires a team with the awareness, communication, and leadership skills to anticipate needs and respond with confidence. In 2024, we launched a leadership development program and restructured our teams to better align expertise with customer goals. This shift has brought clearer roles, faster collaboration, and a shared philosophy of proactive partnership across the organization.

“The availability for growth at Continental Diamond Tool is outstanding,” says Zeb Domer, VP of Bonded Products, who began his CDT journey as a process engineer. “We’re committed to growth and service, and that extends to our people. We make sure our engineers have the tools, training, and leadership support they need to advance their careers right here.”

At CDT, professional development is encouraged, recognized, and celebrated. For Daniel, that support has transformed his early career into a journey of hands-on learning, high-tech engineering design, and leadership development.

“The most exciting thing about being here at CDT is all the experience I’m gaining— learning how to be an engineer, how to design, how to work with people, and soon enough, how to be a leader.”

At Continental Diamond Tool, customer challenges drive our adaptation, and it’s the engineers and technical specialists of today who are shaping the tools that make tomorrow possible.

Join the Team

If you’re a product engineer, process engineer, or problem solver who’s ready to shape the future of manufacturing, there’s a place for you at CDT. Here, you’ll gain experience with advanced materials, cutting-edge processes, and the mentorship to keep growing throughout your career. We believe in developing talent from within and giving every team member the chance to get creative and make an impact.

Check out our Careers page to see available opportunities. Or if you don’t see a current opening that fits your background, we still want to hear from you. CDT is always looking to connect with exceptional individuals who are passionate about precision engineering and quality craftsmanship. Submit a general application for our facilities in New Haven, Indiana, or Kinmel Bay, Wales, to start the conversation.

Faster, Cooler, and More Efficient Surface Grinding with Blue Moon TZ

CDT and Krebs & Riedel test Blue Moon TZ grinding wheels on the BLOHM PLANOMAT, proving performance in surface grinding operations.

With higher removal rates and cooler grinding performance, Blue Moon TZ has proven to be highly effective in applications that require larger contact zones like surface grinding. To see how this technology performs on the Blohm Planomat surface grinder, watch this video or read the following article.

Blue Moon TZ Grinding Wheel Performance on the BLOHM PLANOMAT Surface Grinder

At Continental Diamond Tool, we’re always looking for ways to help customers push productivity forward without sacrificing quality. That’s exactly what the Blue Moon TZ grinding wheel achieves on the BLOHM PLANOMAT surface grinder. Developed by Krebs & Riedel and offered to manufacturers in North America through CDT, this custom-engineered abrasive features precision-shaped trapezoidal grains that enhance performance in fine-finish applications like surface grinding.

“The Blue Moon TZ enables customers to grind materials much faster,” says Erik Van Meter, Product Manager at CDT. “It enables them to increase their parts per dress, and it enables them to grind with less heat, which obviously is much better for the customer.”

Unique Considerations in Surface Grinding

Surface grinding is used predominantly in the manufacture of tools and molds, where surfaces are machined plane parallel to the circumference or face of the wheel. The growing diversity of materials in these applications demands effective, innovative, and economical grinding solutions.

Surface grinding also presents a unique set of challenges: large contact zones, extended linear passes, and high thermal loads can all impact surface finish and dimensional accuracy. These conditions demand an abrasive that maintains stability and temperature control under stress.

The properties of Blue Moon TZ make it well equipped to meet these challenges. Its microcrystalline, trapezoidal rod-shaped grain delivers high cutting performance while maintaining a very low thermal load in the contact zone. This helps reduce the risk of workpiece burn or distortion, even under demanding grinding parameters.

The Role of Vitrified Bonds in Precision Grinding

Vitrified bond systems have largely prevailed in precision grinding because of their controllable porosity and adaptable microstructure. The bond type allows for customized pore space, ensuring the grinding wheel’s performance aligns with the size of the contact zone between the workpiece and wheel. Larger contact zones, such as those found in surface or creep-feed grinding, benefit from a more open and porous structure. This design helps deliver coolant directly into the contact zone and effectively remove heat and chips during grinding.

The vitrified bond structure used in Blue Moon TZ and other conventional abrasive grinding wheels contributes to its ability to maintain stability, extend tool life, and promote consistent grinding pressure. These characteristics make vitrified-bonded wheels particularly advantageous for productive surface and deep grinding applications.

Proven Results on the BLOHM PLANOMAT

To validate these performance advantages, the CDT team partnered with the experts at United Grinding to test the Blue Moon TZ wheel on the BLOHM PLANOMAT Surface Grinder. Together, they evaluated a range of process performance factors to confirm the wheel’s consistency, efficiency, and grinding stability.

The results of these tests were presented and demonstrated live at the United Grinding Precision Summit, giving attendees an up-close look at how Blue Moon TZ enhances efficiency and grinding consistency on high-performance equipment.

Performance that Speaks for Itself

When it comes to surface grinding, the Blue Moon TZ stands out for its ability to deliver both speed and control. Key benefits include:

Very low risk of overheating while grinding

High removal rates and short grinding timesSelf-sharpening abrasive grain for consistent performance

Extended dressing intervals and long tool life

Reduced cost per unit through improved efficiency

The combination of sharp-edged, self-sharpening grains and a homogeneous, controllable pore structure enables smoother coolant flow and more consistent grinding pressure. The result is improved part quality and longer wheel life.

“Customers have been very happy about CDT offering the Krebs & Riedel line,” Erik adds. “Both companies offer high-quality products, good customer service, and great technical service. There’s been a lot of good collaboration between the customers and the CDT people.”

Collaborating for Quality

The partnership between Continental Diamond Tool and Krebs & Riedel brings decades of engineering experience together to serve North American manufacturers with the latest in grinding technology. Whether that’s conventional abrasives or superabrasives, CDT ensures every customer gets a tailored solution backed by technical expertise and responsive support.

Interested in Blue Moon TZ or other abrasive solutions for your surface grinding operations?

Contact our team today to discuss your application and find the right abrasive solution.

Grinding Solutions for the Unique Challenges of Aerospace

CDT’s aerospace grinding solutions improve precision, reduce downtime, and handle tough alloys, composites, and ceramics for reliable flight performance.

Tailoring Grinding Solutions for the Unique Challenges of Aerospace

In aerospace manufacturing, precision grinding is essential for producing components that must reliably perform under extreme conditions. Whether it’s turbine blades, vanes, or structural parts, these components require tight tolerances, exceptional surface finishes, and consistent performance—all while being made from some of the most challenging materials to grind, such as nickel-based superalloys, titanium, and ceramic matrix composites (CMCs).

The grinding process must balance aggressive material removal, heat management, and tool wear resistance to achieve the required part quality and efficiency. This is where electroplated grinding wheels and diamond rotary dressers provide significant advantages, offering solutions to some of the most persistent challenges in aerospace grinding.

Evolving Challenges in Aerospace Manufacturing

Aerospace manufacturers are continuously refining their production processes to meet increasing performance demands. Several industry trends are shaping the way grinding solutions must adapt:

Advanced Materials Require New Machining Strategies

The use of lightweight, high-strength materials such as carbon fiber composites, aluminum-lithium alloys, and CMCs is growing. These materials improve fuel efficiency without sacrificing structural integrity. However, their brittleness, heat sensitivity, and abrasiveness present machining challenges that require specialized grinding technology to shape them.

Additive Manufacturing Is Changing Component Design

3D-printed aerospace parts often require post-processing to achieve dimensional accuracy and surface integrity. Superabrasive grinding wheels are particularly well-suited for refining these components without inducing stress or altering their properties.

Rising Demand for High-Precision Parts

Increasing global defense spending and increased commercial air travel require manufacturers to produce high-performance components at scale, making efficient and repeatable grinding solutions more critical than ever.

Space Exploration Is Pushing Material Science Forward

New materials developed for satellite technology and space vehicles require grinding solutions that can maintain precision while working with ultra-hard alloys and ceramics, materials designed to withstand the extreme conditions of space.

With these challenges in mind, engineering the right grinding wheel is more critical than ever for ensuring part quality, process efficiency, and long-term performance in aerospace applications.

The Role of Electroplated Grinding Wheels in Aerospace

Electroplated grinding wheels offer a unique advantage in aerospace manufacturing due to their single-layer abrasive structure, aggressive cutting action, and ability to maintain form without dressing. Unlike bonded grinding wheels, where abrasive grains are embedded within a matrix, electroplated wheels expose a full layer of diamond or cBN material, ensuring sharp cutting edges and consistent performance.

How Electroplated Grinding Wheels Address Aerospace Challenges

✔ Maintaining Profile Accuracy: Electroplated wheels hold complex geometries without needing dressing, making them ideal for intricate aerospace components.

✔ High Stock Removal with Minimal Heat Generation: The open structure of electroplated wheels allows for aggressive material removal while features like coolant slots and through the wheel coolant delivery can be added to reduce heat buildup—critical when working with heat-sensitive materials like titanium.

✔ Custom-Engineered for the Application and Material: Abrasive size and type, core accuracy, and uniform plating are all critical to match unique aerospace grinding requirements.

✔ Longer Tool Life, Less Downtime: Electroplated wheels maintain their shape throughout their lifespan, eliminating the need for dressing and reducing machine downtime.

✔ Cost Savings with Strip and Replate Services: CDT offers a customized strip and replate program that allow customers to reuse the same core, reducing costs and lead times while delivering the same high-level performance. Our strip technology safely removes remaining abrasive without damaging the core and returns the tool to “like new” condition after replating. This makes it a more cost-effective and sustainable solution for aerospace manufacturers running frequent grinding operations.

"Electroplated grinding wheels are a great fit for aerospace because they are both precision and efficient. They hold intricate profiles, handle high speeds, and stand up against tough materials like nickel alloys, titanium, and ceramics — plus, with our strip and replate services, customers can extend the life of their tools and keep costs down without sacrificing performance," says Jordan Donnelly, CDT Product Line Manager for Electroplated Products.

Optimizing Grinding Performance with Diamond Rotary Dressers

Precision grinding requires continuous wheel maintenance to ensure optimal cutting efficiency and part consistency. Diamond rotary dressers are essential in aerospace manufacturing for truing and conditioning grinding wheels, ensuring the reliability and accuracy of the grinding process.

Key Benefits of Diamond Rotary Dressers in Aerospace

✔ Consistency Across High-Volume Production: Rotary dressers keep grinding wheels performing uniformly, ensuring part consistency and accuracy from the first to the last component.

✔ Reducing Cycle Times & Increasing Efficiency: Keeping wheels properly conditioned and sharp, minimizes grinding forces and allows for optimum cycle times while maintaining part quality.

✔ Application-Specific Design: Whether the application requires traverse or plunge-style dressing, CDT custom-designs each rotary dresser to specific customer needs and applications.

✔ Manufacturing Customization: Every application is different, thus requiring different solutions. CDT solves this issue by offering sintered, reverseplated, and metal bonded rotary dressers.

"Consistency is everything in aerospace manufacturing. Even the smallest deviation can throw off performance, which is why rotary dressing is so important. Our custom-engineered dressers keep grinding wheels precise and reliable, helping manufacturers get accurate, repeatable results every time," explains Troy Giacherio, CDT Product Line Manager for Diamond Rotary Dressers.

The Advantage of a Multi-Disciplinary Grinding Expertise

While electroplated grinding wheels and diamond rotary dressers provide high-performance solutions, CDT’s expertise extends beyond these technologies—allowing us to approach aerospace grinding challenges from multiple angles.

We have extensive experience working with a variety of:

Bond Types: Plated, resin bond, metal bond, vitrified bond, hybrid bond

Core Materials: Carbon fiber, ceramic, high-tensile strength steel, and many more

Diamond Patterns: Handset, random set, reverse plated, CVD-reinforced

Abrasives: Diamond, cBN, and conventional abrasive grinding solutions

This broad expertise enables CDT to study materials, test performance, and develop tailored grinding solutions that push the boundaries of what’s possible. Our dedicated grinding lab allows us to simulate real-world aerospace applications, testing how new materials react during grinding and refining wheel designs to optimize performance.

This cross-industry experience from both the product and application side fosters innovation, ensuring that we don’t just provide grinding wheels—we provide solutions tailored to the specific needs of aerospace manufacturers.

Expanding Capabilities to Better Supply the Aerospace Industry

To address increasing global demand for aerospace products, CDT is expanding its electroplated grinding wheel production capacity with a new building that will grow its second plating line in Europe. This expansion will increase production efficiency, reduce lead times, and allow CDT to serve aerospace manufacturers at a larger scale.

"Expanding our plating facility is a big step forward. With the new electroplating line, we can speed up production and handle more capacity, getting products delivered faster. It’s all part of CDT’s commitment to innovation and supporting the growing needs of our aerospace customers," says Justin Hughes, Production Manager at CDT Ltd.

Finding the Right Grinding Solution for Aerospace Manufacturing

The challenges of aerospace manufacturing—tough materials, tight tolerances, and growing demand—require advanced grinding solutions that can maintain precision, minimize downtime, and innovate at speed and scale.

With specialized knowledge in electroplated diamond and cBN grinding wheels, advanced diamond rotary dresser technology, and expertise across many other grinding product types, CDT is uniquely positioned to help aerospace manufacturers optimize production processes and innovate for the future.

Contact us today to discuss how CDT’s precision grinding solutions can help optimize your aerospace manufacturing process.

Continental Diamond Tool Limited (CDT Ltd.), based in Kinmel Bay, Rhyl, U.K., is the European subsidiary of Continental Diamond Tool Corporation, headquartered in New Haven, Indiana, U.S.A. For more than 40 years, CDT Ltd. has been a leader in diamond rotary dresser technology, originally operating as Consort Precision Diamond. Since joining CDT, the company has expanded its product line, delivering high-performance diamond plated grinding wheels and other premium superabrasive products to customers worldwide.

2025 President's Message: Reflecting on Growth and the Future

Discover how Continental Diamond Tool's 2024 investments in people, processes, technology, and infrastructure are paving the way for enhanced customer solutions in 2025.

As we usher in 2025, Continental Diamond Tool is proud to reflect on an incredible year of progress and innovation. In this video update, CDT’s President, Nick Viggiano, shares his gratitude and insights, highlighting the milestones and lessons from the past year.

Strong Partnerships: Driven by GRIT

Thanks to the unwavering support of our customers and suppliers, CDT has thrived since 1973. We are grateful to our loyal partners who have been instrumental in making CDT an American manufacturing success story. Guided by our GRIT: Global, Responsive, Innovative Team, being a committed partner remains central to our mission as we deliver superior superabrasive solutions for advanced applications across the world.

2024 Highlights: Advancing to Better Serve You

In 2024, our focus was on making internal improvements to better serve you — our customers. By investing in people, infrastructure, and technology, we strengthened our ability to deliver the precision and quality you expect from us. Here are a few key achievements:

Strategic Leadership: Under the leadership of our new CEO, Brian VanHall, we are strengthening our strategy, structure, and systems to ensure your needs are met with efficiency and excellence.

People-Centered Investments: Our strongest competitive advantage is our people. By attracting and cultivating top talent, we have assembled a team that is committed to making every interaction and product surpass your expectations.

State-of-the-Art Expansion: Our newly expanded 72,000-square-foot Technology Center in New Haven, Indiana, will be a platform for the latest advancements in machining, inspection, and quality control for unmatched product reliability.

Global Growth: With a move underway in Wales to a larger 30,000-square-foot building, we are further increasing our capacity to provide timely support and advanced solutions to a global market.

Lessons Learned: Elevating the Customer Experience

In 2024, we put our focus on what truly matters:

People: By placing the right people in the right roles, our team is equipped and empowered to meet your needs with expertise and responsiveness.

Development: Continuously investing in our people, processes, and products delivers better, more innovative solutions for you.

Quality: Enhancing processes that assess, analyze, and assure product quality, performance reliability, and customer satisfaction.

Looking Ahead to 2025: Focused on You

As we step into the new year, we are energized by the opportunities ahead. We remain deeply committed to our mission of delivering unparalleled solutions while fostering strong partnerships with our customers and suppliers. Our gratitude extends to every individual who contributes to our success, from the dedicated CDT team to our trusted partners.

From all of us at Continental Diamond Tool, we wish you in this dynamic world of manufacturing a prosperous and fulfilling 2025.

You can find CDT’s latest product innovations, expert grinding tips, and company news by visiting our blog, watching our videos, or connecting with us on LinkedIn. Together, let’s make this another year of partnership and success!

How CDT Works Together to Serve Customers Better

Behind every precision tool is a team—and surprising fun facts! Guess who are neighbors, or how many interviews we conducted last year. Read the article to learn more.

Staying competitive in precision manufacturing is about more than customizing the most advanced grinding tools and cutting-edge dressing technology—it’s also about the people and processes that ensure everything runs smoothly. At Continental Diamond Tool, many departments work together to deliver exceptional products and service to our customers. In this blog, we’re highlighting the key players whose efforts behind the scenes uphold our standards of reliability and customer satisfaction.

Let’s explore how our departments—from Executive Leadership to Human Resources, Purchasing, Marketing, IT, Finance, and Administration—play a crucial role in better serving our customers.

Executive Leadership: Setting the Vision

Leadership is the compass that guides a company toward success. Our Executive Leadership team sets strategic direction, defines goals, and ensures alignment of our department initiatives with market demand. From expanding facilities for electroplating with diamonds to encouraging development of custom hybrid bonds, our leadership fosters a culture of innovation, reliability, and customer focus.

Fun Facts:

Continental Diamond Tool is a second-generation family-owned company. CDT President Nick Viggiano succeeded his father, Ray, who founded the company in 1973. Under Nick’s leadership, the company has become the fastest growing superabrasives company in North America.

Did you know CDT President Nick Viggiano and CEO Brian VanHall are neighbors? The family ties and neighborly spirit run deep in our organization.

Human Resources: Building a World-Class Team

The foundation of any successful company are people. Human Resources Director, Jenni Long, ensures we hire top talent, provide continuous training, and foster a positive workplace culture. By focusing on employee engagement and growth, HR builds a motivated, skilled team dedicated to excellence.

Fun Facts:

This month, Jenni single-handedly processed the open enrollment benefit selections for more than 180 employees. Plus, she’s conducted over 250 interviews this year.

We’re hiring! Join Jenni’s team as an HR Generalist. Click here to apply.

Purchasing: Ensuring Quality and Consistency

In precision manufacturing, quality starts with sourcing the right materials. The Purchasing department ensures our production teams have access to high-quality raw materials and supplies to meet exacting standards. Strong vendor relationships and effective inventory management keep operations efficient and cost-effective.

Fun Facts:

Inventory management is one of many functions this department handles. With more than 2,500 SKUs in our system, Dan Kortenber and Matt Sheehan ensure materials are always available to meet our customers' needs on time.

In his spare time, Matt referees both college and high school basketball.

Marketing: Connecting with Customers

Understanding customer needs is the first step to delivering outstanding service. Our Marketing team identifies trends, gathers feedback, and communicates the value of our products. From digital campaigns to trade shows, they ensure customers are informed, engaged, and confident in our expertise.

Fun Facts:

The Marketing team led by Carrie Fisher manages more than 150 projects at any given time, ensuring CDT stays innovative, engaged, and ahead of industry trends.

Did you know Marketing Generalist Stacy Viggiano is the wife of CDT President Nick Viggiano? In her role, she wears many hats, bringing her creativity, humor, and authenticity to the company’s communication initiatives.

IT: Empowering Precision with Technology

In today’s digital world, technology is integral to success. Our IT team ensures seamless communication, data security, and operational efficiency by managing robust networks and advanced software. Their work keeps CDT at the forefront of innovation, enabling precision and speed for our customers.

Fun Facts:

IT Director Jeremy Geier bridges the networks between our U.S. and U.K. facilities, enabling seamless and secure order processing and tracking between facilities.

Off the clock, Jeremy coaches the local, CDT-sponsored high school softball team in New Haven.

Finance: Driving Strategic Resource Management

The Finance team led by CFO Mike Brouwer ensures every resource decision is grounded in sound financial planning. They develop budgets, manage expenses, and forecast trends, allowing CDT to invest in resources needed for growth and innovation. Their expertise helps us maintain competitive pricing without compromising quality.

Fun Facts:

Did you know Accounting Manager Joseph Norris has been with CDT for 20 years? Joseph started as a part-time employee working with manual lathes on the shop floor. In 2014, he moved into a full-time role within the Electroplated team. In 2017, Joseph joined the Finance team and is instrumental with the many hats he wears.

Mike and Joseph both enjoy coaching sports outside of work.

Administration: Keeping TEAMS Running Smoothly

Behind every smooth operation is a team ensuring day-to-day activities run without a hitch. The Administration team provides essential support across departments, coordinating schedules, managing communications, and ensuring every detail is handled efficiently.

Fun Fact:

Amy Frecker at our front desk personally answers an average of 50 or more calls every day.

A Unified Effort for Superior Customer Service

Creating custom grinding tools for precision manufacturing applications is complex, but it’s made possible by the collaboration of diverse departments working toward a common goal: customer satisfaction. At Continental Diamond Tool, every team plays a important role in meeting and exceeding the demands of the industries we serve.

Whether it is our groundbreaking work in our grinding lab at CDT New Haven or our industry-leading processes in our 500-tank lab for electroplating with diamonds, it’s not just about what we make—it’s about how we work together to serve you better.

You’ll notice we share a love of teamwork and a spirit of camaraderie at CDT that extends beyond our workdays. Many of our team members coach or referee sports outside the office—be it basketball, softball, or other athletic programs—carrying forward the same principles of sportsmanship, collaboration, and high performance that we bring to serving our customers. These values are core to who we are, both on the shop floor and on the playing field.

Have questions about how we can help with your precision manufacturing needs? Contact us today to learn more about our commitment to excellence.

CDT’s Lab Evaluates Blaser Coolants in Flute Grinding Applications

Check out how we tested Blaser coolants on EVO hybrid bond wheels in CDT’s grinding lab to see which best enhances cutting, tool life, and quality in precision flute grinding.

At Continental Diamond Tool (CDT), we pride ourselves on pushing the limits of grinding technology. In one recent trial, The Grinding Chronicles team has partnered with Blaser Swisslube to test the performance of different coolants on our EVO hybrid bond grinding wheels. This experiment in CDT’s grinding lab aims to determine which coolant best enhances cutting performance, tool life, and workpiece quality in precision flute grinding applications.

Parameters for Success

Leading this effort is CDT Application Engineer Harrison Sheldon and CDT Engineering Consultant Jon VanSant, who are testing three different Blaser fluids under controlled conditions. They are measuring key parameters such as power, force, and grinding wheel wear while closely inspecting the visual quality of the workpiece for signs of burn or other surface finish issues.

“Our focus is on how the grinding wheel cuts, wears, and the resulting workpiece quality,” Jon explains. “By measuring parameters like power and force, we aim to collect data that can objectively compare the performance of each coolant under consistent conditions.”

Three representatives from Blaser joined Harrison and Jon last week at CDT’s lab: Senior Application Engineer Brett Reynolds from the New York plant, and Grinding Business Development Managers Tom Cappadona, also from New York, and Simon Stalder, representing Blaser’s headquarters in Switzerland. For this trial, Blaser has provided the coolant fluids, while CDT is supplying the EVO hybrid bond grinding wheels and the data collection equipment in the grinding lab. This setup ensures a comprehensive, scientific approach to analyzing performance with these coolants.

“When Tom approached us about this trial, we saw an opportunity to try something new with the equipment in our grinding lab,” says Harrison. “We’re excited to see how each formula stacks up to help the team at Blaser guide their customers in optimizing their process.”

Simon Stalder expressed his enthusiasm for the trial results, eager to share the findings with his engineering team in Switzerland. These results will provide valuable insights into how Blaser’s latest coolant technology enhances grinding performance and efficiency. As a global leader in metalworking fluids, Blaser delivers tailored formulas for every material, industry, and application.

Benefits of a Dynamic Testing Environment

The dynamic testing environment in CDT's grinding lab allows Harrison and Jon to adjust parameters on the fly, testing variables such as feed rate while maintaining consistent wheel speed. This enables them to evaluate the optimal feed rate range for each coolant type.

“One key advantage of running trials in the lab is the ability to collect objective data in controlled conditions,” says Jon. “Unlike in the field, where varied operator techniques can affect outcomes, our lab setting allows us to isolate variables and focus on actionable insights.”

While Blaser has come to CDT's lab primarily for the technical instrumentation and grinding know-how of our team, customers do not have to travel to take advantage of the lab’s capabilities. “CDT’s grinding lab is exceptionally flexible due to its portability. We frequently gather data directly from our customers’ processes by installing equipment at their site and analyzing it in our lab,” Harrison notes, “or we can simulate their operations on our machines and collaborate remotely to tweak their process.”

The expertise of Blaser’s application engineer, Brett Reynolds, has also been instrumental in these trials. “Brett brings a deep understanding of Blaser’s fluid formulation and their customer applications, which complements our grinding expertise,” adds Jon.

Trials on the Walter Helitronic Machine

As a 5-axis tool and cutter grinder, the Walter Helitronic is a purpose-built machine that is a centerpiece in CDT’s grinding lab and perfect for trials like this. Its versatility and precision are critical for evaluating different grinding configurations.

“The Walter machine is capable of thousands of functions, but it’s most commonly used for round cutting tools, making it perfect for flute grinding trials with our EVO Hybrid Bond fluting wheels,” Harrison says. “Its high precision, repeatability, and compatibility with advanced cooling systems make it the ideal platform for these tests.”

Jon elaborates, “The Walter allows us to make real-time adjustments to speed, feed rate, and pressure, which is essential for testing performance during these trials. Its automation and sensitive readings ensure accurate, repeatable results.”

The team at Blaser is currently reviewing the data gathered from last week’s trial and discussing how to incorporate the insights into future marketing and product development.

Accessing Our Grinding Lab Services

At CDT, we believe in the importance of real-world testing to optimize grinding processes and improve part quality. Our grinding lab is available for trials like these, whether you’re testing new grinding wheels or assessing some other metric of performance.

“Our team’s diverse areas of expertise ensures we can accommodate unique customer needs,” Harrison shares. “Whether it’s conducting tests in our lab or traveling to your site, we provide valuable solutions tailored to each challenge.”

If you’re interested in running a grinding trial with CDT, contact us with details about your process. We can recreate it in our lab or connect at your facility to gather data. From there, we develop testing parameters, share results, and make tailored recommendations for specific tools and production settings.

Learn more about Blaser Swisslube at:

Linkedin.com/company/blaser-swisslube

Youtube.com/user/blaserswisslube1

Brian VanHall Hired as CEO of Continental Diamond Tool

Continental Diamond Tool announces Brian VanHall as the new CEO to advance the company's mission of delivering high-quality, custom-engineered tooling solutions to customers around the world.

New Haven, Indiana – May 31, 2024 – Continental Diamond Tool is delighted to announce the hiring of Brian VanHall as the Chief Executive Officer, starting June 3, 2024. Founded in 1973, Continental Diamond Tool is a global leader in the design, manufacture, and application of precision grinding products for a multitude of industries.

Brian VanHall has been hired as the Chief Executive Officer at Continental Diamond Tool, starting June 3, 2024

As CEO of Continental Diamond Tool, Mr. VanHall is excited to advance the company's mission of delivering high-quality, custom-engineered tooling solutions to customers around the world. “I am honored to be entrusted by the Viggiano family and CDT team to help grow the legacy of excellence in developing and delivering innovative solutions for advanced manufacturing applications” said VanHall.

Mr. VanHall previously served as Executive Vice President with Ambassador Enterprises. With over 20 years of executive experience, Mr. VanHall brings a record of leading innovative projects, transformative programs, and strategic partnerships for multinational organizations to grow economic value, organizational effectiveness, and social impact. Brian received his Master of Business Administration (MBA) from Baylor University and holds graduate certifications in organizational leadership, corporate governance, strategic planning, and project management.

Nick Viggiano, President of Continental Diamond Tool, said, “We are excited to welcome Brian VanHall to the team and look forward to a future of continued excellence and growth with his leadership.”

For more information about our management team at Continental Diamond Tool, click here.

About Continental Diamond Tool Corporation:

Established in 1973, Continental Diamond Tool Corporation (CDT) is a premier manufacturer of precision tooling solutions for industries worldwide. With a legacy of technical expertise and innovation, CDT is renowned for its custom superabrasive grinding wheels and diamond dressing tools. CDT is also North America’s exclusive source for Krebs & Riedel conventional abrasive wheels, which are custom profiled at our facility. Headquartered in New Haven, Indiana, CDT operates a state-of-the-art 200,000 sq. ft. manufacturing center dedicated to delivering high-quality products and exceptional customer service. Learn more >

Continental Diamond Tool Enters Strategic Partnership with Krebs & Riedel

Continental Diamond Tool Corporation partners with Krebs & Riedel, becoming the exclusive source for their abrasive products in North America. Learn more about the collaboration in this article.

New Haven, Indiana – April 30, 2024 – Continental Diamond Tool Corporation (CDT) proudly announces its partnership with Krebs & Riedel, a global leader in the abrasives industry. This collaboration positions CDT as the exclusive North American source for Krebs & Riedel abrasive products within the USA, Canada, and Mexico.

Nick Viggiano, President of Continental Diamond Tool (left), and Florian Riedel, Managing Director of Krebs & Riedel.

Erik Van Meter, Senior Product Manager of Conventional Abrasives at Continental Diamond Tool and Krebs & Riedel’s official representative, expresses enthusiasm about the new partnership, stating, "We are thrilled about the high-quality products Krebs & Riedel will bring to the table. They are a well-respected name in conventional grinding wheels and have products for many industrial grinding markets which include automotive, aerospace, gear and medical."

The collaboration between CDT and Krebs & Riedel signifies a partnership deeply rooted in a shared commitment to excellence. For more than half a century, Continental Diamond Tool Corporation has consistently delivered technically superior precision grinding products across a variety of industries. As a thriving second-generation family business, CDT’s commitment to innovation and quality is reflected in its state-of-the-art North American manufacturing facility, which is undergoing a sizable expansion to cater to new product development and meet diverse customer needs. With this and a growing subsidiary in the United Kingdom, it has solidified its status as a premier worldwide manufacturer of custom superabrasive grinding wheels and diamond dressing tools.

Similarly, Krebs & Riedel is a family-owned enterprise headquartered in Bad Karlshafen, Germany, since 1885. It has a proud century-long legacy in providing quality abrasive products globally. With over 30 distributors and subsidiaries, K&R's dedication to customer satisfaction aligns seamlessly with CDT's founding principles. This partnership promises cutting-edge solutions and unwavering commitment to superior products and customer service in the abrasive products landscape. In this strategic move, CDT and Krebs & Riedel are poised to tackle the most critical tooling requirements of a growing market of customers.

“This partnership marks an exciting chapter for Continental Diamond Tool Corporation as we join forces with Krebs & Riedel to expand our product offerings in North America,” said Nick Viggiano, President of CDT. “We are proud to align with Krebs & Riedel's esteemed reputation and look forward to delivering exceptional abrasive products and unparalleled service to our customers across the continent and beyond.”

“With CDT we have found the partner who complements our high-performance products with superior service. From the first meeting we felt the same level of professionality and passion for grinding. I am convinced that our customers in North America will feel the same,” said Florian Riedel, Managing Director of Krebs & Riedel.

For more information about Continental Diamond Tool Corporation and its comprehensive range of precision grinding products, including those from Krebs & Riedel, please visit www.cdtusa.net/products.

Continental Diamond Tool Corporate Office in New Haven, Indiana, USA

About Continental Diamond Tool Corporation:

Established in 1973, Continental Diamond Tool Corporation (CDT) is a premier manufacturer of precision tooling solutions for a variety of global industries. With a legacy of technical expertise and innovation, CDT is renowned for its custom superabrasive grinding wheels and diamond dressing tools. Headquartered in New Haven, Indiana, CDT operates from a state-of-the-art 200,000 sq. ft. manufacturing facility dedicated to delivering high-quality products and exceptional customer service.

Krebs & Riedel Head Office in Bad Karlshafen, Germany

About Krebs & Riedel:

Family owned since its start in 1885, Krebs & Riedel (K&R) has been a prominent global player in the abrasive products industry. With a vast network of over 30 distributors, subsidiaries, sales companies, and representatives worldwide, Krebs & Riedel is renowned for its quality abrasive products and commitment to customer satisfaction.

Top 10 Reasons to Work Third Shift at CDT

From longer weekends to higher pay, check out the top ten reasons you should apply for a third shift position at CDT.

Here at Continental Diamond Tool, we take our work seriously, but that doesn’t mean we don’t have a sense of humor! Whether you think of third shift as a “late shift” or a “late show,” there are lots of great reasons to work nights at CDT.

From longer weekends to higher pay, watch the video below to see the top ten reasons you should apply for third shift at CDT.

Drumroll please…..

CDT Starting A New Third Shift

Continental Diamond Tool has experienced extensive growth in Three of their most popular product lines, and they are now adding a third shift to their schedule to increase production and continue to fulfill global orders in a competitive timeframe. Apply today >

Continental Diamond Tool Starting A New Third Shift, Now Hiring

Continental Diamond Tool has experienced extensive growth in three of their most popular product lines, and they are now adding a third shift to their schedule to increase production and continue to fulfill global orders in a competitive timeframe.

The new shift will consist of four 10-hour shifts per week, from 8 p.m. to 6 a.m. This third shift will begin as soon as the open positions are filled, which may be as soon as August. All positions are entry-level and require a high school diploma. Job training will be provided.

CDT fosters an innovative, team-oriented environment for their employees, who enjoy paid lunch breaks, competitive wages, and health insurance benefits, along with additional benefits and overtime opportunities, in a clean, climate-controlled environment.

In business since 1973, CDT is a leading producer in the global market for superabrasive grinding wheels and custom tooling. Their 128,000 sq. ft. manufacturing facility in New Haven, Indiana, utilizes the latest technology to serve numerous industries including medical, aerospace, power generation, and more.

Additional information and applications are available by calling 800-443-6629 or visiting CDTUSA.net/careers.