How Dressing Interval Affects Profile Retention, Scrap, and Cost per Part

Most grinding issues do not appear suddenly. Instead, the condition of the grinding wheel gradually breaks down during the production run until parts fall out of spec. Regular dressing and truing help keep wheel wear in check.

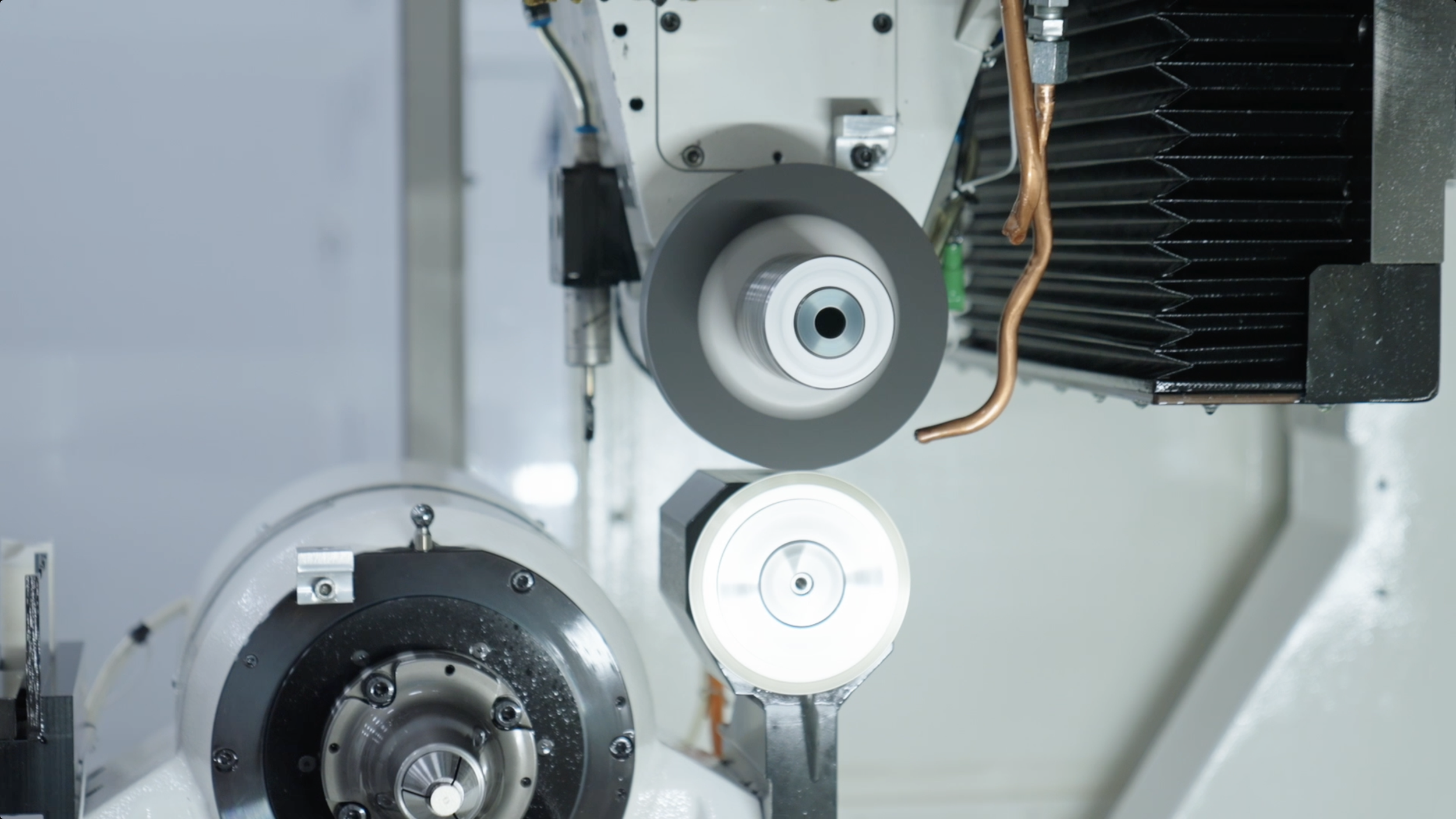

At Continental Diamond Tool (CDT), we approach the dressing interval as an important variable that directly influences performance. From our facility in Wales, we design and manufacture high-precision reverse-plated rotary diamond dressers tailored to specific grinding applications. CDT sales and application engineers are available to provide operating guidance on dressing frequency to balance tool life, part quality, and process stability.

What Happens During Grinding and Dressing

Grinding

As grinding wheels wear, several mechanisms work against consistent grinding performance:

Dulling of abrasive grains, which reduces cutting efficiency

Material loading, which interferes with chip formation

Glazing, which increases heat generation

Left unchecked, these effects reduce cutting performance and contribute to loss of profile accuracy and dimensional control.

Dressing and Truing

The process of dressing and truing restores wheel geometry, exposes fresh cutting edges, and establishes the surface condition required for stable material removal.

An optimized dressing interval helps maintain:

Consistent wheel sharpness

Stable grinding forces

Predictable thermal behavior

Reliable dimensional control

Because wheel condition changes continuously during grinding, dressing must be applied at a defined interval to maintain consistent performance. How often dressing and truing are applied determines whether wheel wear remains controlled or turns into scrap, rework, and downtime.

The Consequences of Late-Run Scrap

In a perfect world, the grinding wheel would maintain its condition for the full production run. In reality, wheel wear progresses independently of any planned production cycle. Changes are often subtle at first, making it difficult to identify exactly when part quality has drifted out of spec.

As wheel condition deteriorates, shifts in cutting behavior, heat generation, and material removal can go unnoticed. By the time late-run scrap is identified, multiple components may already be affected. Earlier parts may need inspected again to determine when the process first deviated, adding unplanned downtime.

Late-run scrap is particularly disruptive because it combines material loss with lost time for investigation, reinspection, and stabilizing production. Maintaining consistent wheel condition through regular dressing helps limit process variability, reduce late-run scrap, and minimize the investigation and recovery effort that often accompanies end-of-run failures.

Are You Dressing Too Often—or Not Often Enough?

While dressing and truing are essential to many grinding processes, it is possible to have too much or too little of a good thing.

Over-Dressing

It may be tempting to dress more frequently to head off quality issues before they can develop. However, over-dressing accelerates wear on both the grinding wheel and the diamond dresser. Each dressing cycle removes usable abrasive material and incrementally wears the diamond roll.

When dressing intervals are too short, this can result in:

Accelerated wear of the grinding wheel and diamond dresser

Increased downtime for wheel and roll changes

Higher tooling and maintenance costs

Frequent interruptions for dressing reduce productive grinding time, negatively impacting throughput and cost.

Under-Dressing

At the other extreme, trying to maximize overall productivity by delaying dressing until problems arise introduces a different set of issues. Under-dressing allows wheel wear, loading, and glazing to accumulate.

As the wheel loses cutting efficiency and geometric accuracy, the process becomes unstable. Common consequences include:

Unacceptable surface finish

Thermal damage or burn

Chatter and vibration

Dimensional variation out of tolerance

Not only does this create scrap, it also prolongs downtime. In many cases, multiple dressing cycles are required to restore the grinding wheel’s geometry. Extended dressing time accelerates diamond roll wear and delays the return to stable production.

The optimal dressing interval lies between these extremes and must balance wheel sharpness, profile accuracy, and tool life.

Is There a “Recommended” Dressing Interval?

This is one of the most misunderstood questions in dressing.

There is no universal dressing interval that works equally well for every grinding process. Dressing performance depends on a complex interaction of variables, including:

Grinding wheel specification, including abrasive type, bond, and structure

Workpiece material and hardness

Stock removal rates

Wheel speed and feed parameters

Dressing method and dressing ratios

Required surface finish and profile tolerances

At CDT, we produce dressers for multiple dressing methods, each with its own ratios and parameters to condition the grinding wheel correctly for the application. A dressing interval that performs well for one material or geometry may produce burn, chatter, or profile loss in another.

For this reason, dressing should be treated as an engineered process decision rather than a fixed rule. Optimizing dressing frequency is best achieved by evaluating the entire grinding system and making adjustments based on actual process behavior.

Dressing as a Lever for Cost per Part

When dressing intervals are optimized, the benefits extend beyond part quality. A stable dressing strategy contributes to:

Longer grinding wheel life

Extended diamond dresser life

Reduced unplanned downtime

Lower scrap rates

More predictable production schedules

All of these factors directly influence cost per part. In high-value grinding applications, even modest improvements in tool life or scrap reduction can yield meaningful cost savings over the life of a program.

Conversely, poorly optimized dressing intervals may be explained away as wheel problems or undiagnosed process variability when the underlying issue lies in how often the wheel is being dressed.

Partnering on the Right Dressing Strategy

Because dressing behavior is highly application-specific, the most effective solutions are developed through collaboration. Optimizing dressing frequency requires evaluating the entire grinding system and adjusting based on real process behavior rather than generic recommendations.

CDT maintains a team of experienced sales and application engineers who can support customers, when needed, in collecting and analyzing process data to identify the optimal dressing interval for their application. If a grinding process shows signs of instability, late-run scrap, or excessive tool wear, the dressing interval is often one of the most impactful process variables to review for improving overall performance.

Continental Diamond Tool Limited (CDT Ltd.), based in Kinmel Bay in Wales, is the European subsidiary of Continental Diamond Tool Corporation, headquartered in New Haven, Indiana, U.S.A. For more than 40 years, CDT Ltd. has been a leader in diamond rotary dresser technology, originally operating as Consort Precision Diamond. Since joining CDT, the company has expanded its product line, delivering high-performance diamond plated grinding wheels and other premium superabrasive products to customers worldwide.