News and Resources

Browse by Category

Browse by Product

- All Dressing Products

- All Grinding Products

- CBN-Diamond Superabrasives

- Conventional Abrasives

- Diamond Lapping Compounds

- Diamond Rotary Dressers

- Diamond Stationary Dressers

- Hybrid Bond Grinding Tools

- Metal Bond Grinding Tools

- Plated Grinding Tools

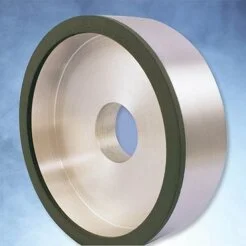

- Resin Bond Grinding Tools

- Vitrified Bond Grinding Tools

How to Match Your Resin Bond Grinding Wheels to the Workpiece

Superabrasive grinding have two equally important components. While the grit, (diamond or CBN,) does the work, it couldn't function without a partner holding it in place. In the case of resin bond grinding wheels, that partner is phenolic resin.

Superabrasive grinding wheels have two equally important components. While the grit, (diamond or CBN) does the work, it couldn't function without a partner holding it in place. In the case of resin bond grinding wheels, that partner is phenolic resin.

The hardness of the phenolic, along with grit size and concentration, determines wheel life, material removal rate, and final surface finish. CDT controls these three parameters precisely, allowing users to match a wheel to the particular workpiece material and type of grinding operation. However, selecting the best wheel depends on understanding the relationship between hardness, grit size and concentration and the wheel wear mechanism.

WHEEL WEAR MECHANISMS

As grit cuts through the workpiece material the edges become dull. Allied to that, chips from the cutting process erode the resin, releasing old grit and exposing fresh edges. The rate at which fresh grit is exposed is critical. Dull edges tend to rub against the workpiece, cutting forces go up and more heat is generated, perhaps burning the workpiece. Conversely, if grit is released early the grinding wheel is wearing faster than necessary, resulting in more frequent replacement.

HARDNESS

Hard workpiece materials, like ceramics and carbides, tend to dull cutting edges quickly, yet because the chips are small and brittle, resin wear is low. In this situation, to ensure a sufficient supply of fresh new cutting edges it's best to use a softer wheel.

Softer materials, like steels and high nickel alloys, (which should be ground with CBN rather than diamond,) produce longer, more ductile chips. These erode the resin faster which, in a soft wheel, results in excessive wear.

Manufacturers of resin bond grinding wheels adjust hardness by varying the mix of fillers in the phenolic resin. The resulting wheel hardness is expressed on a scale from A (softest) to Z (hardest) although superabrasive wheels are generally available just for the range from O through U. If a wheel outside of this range is thought necessary, consult with product specialists here at CDT.

CONCENTRATION

This refers to the proportion of superabrasive grit in the resin and is expressed on a scale of 25, 50, 75, and 100. The highest value indicates a weight to volume ratio of 72 carats per cubic inch, which works out to about 25% by volume.

A higher concentration means more cutting points, which results in faster material removal, but also increases wheel cost. Concentration also affects surface finish: a lower concentration would typically be used for finishing than for roughing.

GRIT SIZE

Larger abrasive particles remove more material on each pass, so coarser grits are used for rough machining and when grinding softer materials. Smaller particles lower cutting forces, so are used for harder materials as well as finishing operations.

MATCH THE WHEEL TO THE WORKPIECE

The choice of grinding wheel depends on the nature of the workpiece material and whether roughing or finishing. Harder materials generally should be ground with a softer wheel and small grit size. Softer materials are better ground with harder wheels and larger grit. Grit concentration should be chosen to suit the type of grinding operation – roughing or finishing.

If in any doubt as to the hardness of wheel to use, consult a grinding wheel specialist.

Diamond Lapping Compounds

CDT lapping and polishing compounds are excellent for mold, die, and tool polishing.

CDT lapping and polishing compounds are excellent for mold, die, and tool polishing. These compounds also provide superior results when polishing to final tolerance of ceramic parts, tool-room use, and many other high finish and tight tolerance performance applications.

Diamond is the hardest and the most abrasive-resistant material used in nearly every type of industry. Our diamond lapping compounds use these unique characteristics to improve your finishing capabilities. You may choose to add diamond powders to the polishing paste in some instances.

Whether your job calls for high stock removal, fast polishing times, or superior finishes, you can find a compound that will help you achieve better results and a mirror finish. Both water and oil soluble compound are available in 5 and 18 gram syringes. Our syringes are disposable plastic dispensers that are convenient and safe from outside impurities.

Key features and benefits include:

Faster cut rates

High surface finish

Excellent surface tension

Quality viscosity

Low evaporation rate

Key adhesion to tools and surfaces

Easily cleans surfaces with both water and oil

Customers often ask what grit do we use for mold, die, and tool polishing? Our engineers are happy to assist you in finding the best compound for your specific application: 800-443-6629.

Since 1973, CDT has lead the field in providing technically superior precision tooling solutions to numerous industries. If you need rapid, accurate lapping, polishing and super-finishing, contact our technical team to learn more about our diamond lapping compounds.

Common Fluting Mistakes — and How to Fix Them

While superabrasive grit does the grinding, the bond material is every bit as important. Learn how resin bond can produce superior surface finish.

Flute Polish or Flute Burnish?

There is an increasing need for high-quality carbide mills and drills with polished flute faces. Your customers are demanding a surface grinding tool that has a shiny flute, evacuates a metal chip better, and runs at faster speeds.

Sometimes your customer just wants your tool to look like the “other guy’s” tool. Unfortunately, a burnished flute face can be mistaken for true polish. Toolmakers have the challenge of making a cost-effective tool that has great performance and a great finish on the flute face.

Common Fluting Mistakes

Some toolmakers turn to hybrid wheels that grind the flute in no time, but these grinding wheels really don’t polish all that well.

To improve appearances and achieve a smooth finish, a lot of toolmakers use nonwoven products to polish after fluting. But do flute polishing cloths really polish, or do they just burnish the surface?

For a Quality Flute Polish

For a flute cleaning and polishing that really penetrates the surface, you have to remove some material to get through the grind lines leftover after flute grinding.

A resin bonded grinding wheel can give you a finish that is as good or better than nonwoven polishing products, but the resin bonded wheel also removes material from the flute face, taking out subsurface damage.

Resin bond is made by mixing abrasive grit with a phenolic resin. The resulting compound is molded to shape before being baked in an oven. This produces a grinding wheel that's tough, with the resilience to take impacts without shattering. By adding copper and other fillers to the resin base, grinding wheel manufacturers can tailor the properties of the finished grinding wheel to a wide variety of applications.

With resin bond, you can make a tool that not only looks just as good as the “other guy”, but also is actually better quality than the other guy. Resin-bonded superabrasive grinding wheels provide:

Shock-resistance

Excellent surface finish

Low maintenance

The Extra Effort Sets You Apart

The right wheel can help you polish up your act. CDT’s resin bond flute polishing wheel performs as good as it looks — producing a quality tool that shows. We offer resin bond polishing wheels to work in oil or emulsion on all CNC cutter grinders. These grinding wheels can run at high speeds and are available in grits as fine as 1200 or more based on finish requirements.

Grinding wheel manufacturers have years of experience and there are few fluting applications we haven't encountered. Our engineers can help you get the right grinding and polishing solution for your particular application.

Precision Finishing With Diamond Lapping Compounds

In many applications the finish resulting from grinding is good enough. When it isn't, the next step is lapping. As with grinding, diamond makes an excellent abrasive, but for best results needs to be selected and used appropriately.

A good quality grinding wheel on a rigid machine can produce a surface with a roughness around 0.25 microns Ra. In some applications this isn't enough; in others flatness is of greater importance than finish. In either situation the next step is to move on to lapping.

PRECISION FINISHING

In lapping an abrasive compound, composed of abrasive particles in a liquid or paste transport medium, is placed between the work piece and a lapping plate. Movement of the plate rolls the particles across the surface, removing raised peaks and flattening high regions. Depending on the work piece material, roughness numbers of under 0.30 microns Ra are achievable.

Other reasons for lapping are to bring something down to a precise and uniform final size and to produce a very flat surface. (Think of flatness as the rolling of hills and valleys, while roughness is the furrows plowed in the field.) Lapping doesn't put any stress or heat into the surface, and the low cutting forces make it a distortion-free way of finishing thin-wall parts.

LAPPING WITH DIAMOND COMPOUNDS

A number of abrasives can be used but diamond has several advantages:

highest material removal rates, by virtue of it's exceptional hardness

excellent surface finish, because the edges cut cleanly and diamond can be graded down to micron-level. (Producing a uniform, scratch-free surface demands particles of the same size: any that are larger will produce undesirable scratches.)

When lapping, standard practice is to use a cast iron lapping plate. For lapping with superabrasives (diamond or CBN) though it's recommended to use a composite metal plate such as tin, copper or cast iron.

The transport medium used in a diamond lapping compound can be either oil or water soluble. Oil soluble compounds are the most common and can be used on ceramics, carbides, cast iron and other metal surfaces.

A water soluble compound is used when the work piece is sensitive to oil. It's often employed for finishing electronic and electro-optical components and is widely used for magnetic read/write heads and semiconductor applications.

Companies like CDT supply precisely graded diamond lapping compound in syringes for easy dispensing. The coarsest grades, in the region of 40 to 90 microns, gives rapid stock removal while smaller particle sizes are used for finishing. To give one example, an application like preparing metallographic samples needs abrasives of less than two microns in size.

CHOOSE YOUR DIAMONDS CAREFULLY

In many applications the finish resulting from grinding is good enough. When it isn't, the next step is lapping. As with grinding, diamond makes an excellent abrasive, but for best results needs to be selected and used appropriately.

Understand Dresser Options To Cut Costs

Dressing is at the heart of a simple process: Use a diamond to expose fresh grit on the grinding wheel to extend its life. Yet there are dozens of different dressing tools — learn which to choose.

If you look at “Dressers “ or “Diamond Rolls” on the CDT website, it reveals several different types. Dressing is at the heart of a simple process: Use a diamond to expose fresh grit on the grinding wheel, so why so many tool options?

Focus on cost per piece

Stopping to sharpen the wheel means lost production, so it’s tempting to dress infrequently and to do it as fast as possible. Most shops know that’s a mistake, so they look for other routes to cut costs.

For some that means buying the cheapest single point dressers they can find. That’s often false economy. Instead they should try to minimize the dressing cost per work piece. That might mean buying better quality or more sophisticated dressers, which is why so many different types are offered.

Single point

The single point diamond dresser is the workhorse of grinding. It works in practically every application but is especially effective on straight wheels and for creating simple profiles. Special variants of the single point dresser are used for thread forms.

Diamonds aren’t cheap though, especially the better quality ones that better resist microcracking, so it’s important to get as much life from the dresser as possible. That means rotating the diamond regularly and changing the face exposed to the wheel to even out the wear.

Some diamond dressers are resettable, meaning the diamond can be reoriented to expose a fresh point. That adds to the cost but can mean an overall saving when compared with nonresettable dressers that are effectively throwaway items.

Multipoint dressers

In multipoint dressers, several diamond points work together to dress the grinding wheel. They work well for straight pass grinding on larger OD wheels as well as surface and centerless wheels.

A special form of the multipoint dresser is the donut cluster. These consist of a large number of diamonds set in a large crown. Good for dressing large wheels quickly, they are especially recommended for use on cylindrical grinders.

Grit dresser tools

Continuing the progression toward more dressing points, these tools use a diamond grit rather than discrete diamonds. These are long-lasting and allow for rapid dressing, making them very cost effective.

Blade dressers

Similar to a chisel in appearance, these present a line of diamond to the wheel. While they work for straight dressing, it’s more common to use them for profiles. Blade dressers come in both fixed and swivel head geometries for additional versatility.

Rotary diamond dressers

Rotary Diamond Dressers are a highly efficient and cost effective means of dressing and truing grinding wheels. Their use in achieving accurate correct form, tolerance, and condition is rapidly growing in the automotive, aerospace, power generation, machine tool and precision engineering component manufacturing.

Not an easy choice

There are several routes to minimize dressing cost per work piece and even for experienced machinists, it’s not always obvious which to take. That’s why it’s advisable to consult with experts to determine the best type of dresser for your application.

Grind Quickly And Accurately With A Vitrified Superabrasive Wheel

When high material removal and dimensional control is a concern, a vitrified wheel should be the first choice. Learn more benefits of a vitrified wheel >

High material removal rates demand a lot from the workpiece-machine-wheel system. Everything deflects under the high loads, making it difficult to achieve precise control over finished workpiece dimensions.

To combat this grinding machine manufacturers engineer-in as much rigidity as possible, but the wheel has a part to play as well. Resin-bonded wheels tend to “give” slightly under load, making it hard to meet tight tolerances whereas vitrified wheels provide much higher stiffness. This is because the Vitrified wheel is essentially composed of abrasive bound in a ceramic bond that doesn’t deflect as it contacts the workpiece, so size control is better.

VITRIFICATION BENEFITS

A vitrified superabrasive wheel begins life as Diamond or CBN grit incorporated into a specialized ceramic bond. After being formed to the required wheel shape this goes into a kiln where it’s fired at high temperature to fuse the abrasive to the bond. The superabrasive is both mechanically and chemically held.

This provides five other benefits in addition to stiffness:

Low wear rates

Thermal stability – which helps size control

Open structure enables coolant delivery to the grinding zone, keeping interface temperatures down

Oils and other fluids have no effect on wheel integrity

Dress-able, allowing precise forms and extending life

APPLICATIONS

Vitrified superabrasive wheels have a much longer life than conventional Silicon Carbide or Aluminum Oxide grinding wheels and provide exceptionally rapid material removal. This makes them attractive for high volume applications where cycle time and downtime must be minimized.

Vitrified diamond wheels are ideal for grinding PCD cutting tools, as well as carbides, cermets and ceramics. Vitrified CBN wheels are more suited for ferrous metal applications like camshaft and crankshaft grinding in the automotive industry or tool and die machining.

A further advantage of vitrified wheels is the possibility of customization to suit a specific application. Consult CDT to learn what's possible.

CAUTIONS

Glass is brittle and so is a vitrified wheel. It will break down under high pressure. This also means the wheels need to be engineered for the application.

Because of the porous structure of the Vitrified wheels, it is important to adjust the corresponding grit size to match finish when comparing/converting from conventional abrasives or Resin and Metal Bond wheels.

THE HIGH VOLUME SOLUTION

When high material removal is needed and dimensional control is a concern a vitrified wheel should be the first choice. Its high stiffness and porous structure allow rapid grinding while minimizing deflection in the workpiece-machine-wheel system. Add in long life and the result is a wheel suited to the most challenging high volume applications.

Why Use Plated Diamond or Cubic Boron Nitride Tools?

Coatings applied during the plating process are either metallic, diamond, or cubic boron nitride. Learn the properties of each and which is best >

Layering metal parts via electrolysis with special substances that improve their strength or appearance and protect parts from oxidation and corrosion is called electroplating. Typically less than .05 millimeters thick, coatings applied during the plating process are either metallic, diamond, or cubic boron nitride. Decorative objects such as jewelry or tableware are usually plated with silver or gold while steel and iron items are plated with zinc, chromium, nickel or tin. However, grinding tools require cubic boron nitride or diamond coatings to optimize their functioning, provide better cutting action and deter rapid deterioration of tools.

Advantages of Electroplated Diamond Tools

Tools sent through an electroplating process that coats them with a diamond layer cleaved by a tough nickel alloy retain their precise proportions and original structure throughout their working life. Unlike resin bond or metal bond diamond products involving diamond particles that have been cached in bond and joined together by embedded resin or metal binder, electroplating facilitates the protrusion of diamond fragments to extend beyond the bond matrix. This further provides electroplated diamond tools with the exceptional ability to cut freely and rapidly without generating excessive heat. Less heat generation means better grinding efficiency, reduced risk of cracks or burns on the workpiece's surface and a significant decrease in equipment energy consumption.

Electroplated diamond tools are well-suited to process:

Abrasive or hard non-metallic entities such as asphalt, stone, ceramics, concrete, semiconductor materials and glass.

Non-ferrous metals (copper, aluminum and their alloys) and pliable but tough materials (resin and rubber, for example).

Since diamonds react with iron, cobalt, nickel, chromium and vanadium under elevated temperatures produced during grinding actions, diamond tools should not be used to process common steels and tough alloy steels. For work involving these materials, electroplated cubic boron nitride tools are recommended.

Advantages of Electroplated Cubic Boron Nitride Tools

Considered the best technological advancement made for facilitating grinding of superalloy and hardened ferrous materials, cubic boron nitride is second to diamonds on the hardness scale and offers nearly five times the abrasion resistance afforded by traditional abrasives. Electroplated CBN tools also provide the following additional benefits not found in any other electroplated tools:

Remarkable thermal conductivity and chemical resistance

Enhanced surface integrity for grinding hardened cobalt-based superalloys as well as nickel and hardened alloy steels

Eliminates the expense of post heat-treat grinding operations

Produces polished surface finishes by providing taut dimensional management of tools to users

Creates no bit-dulling grit

The ability to induce nanostructuring of carbon boron nitride has allowed engineers to further increase the hardness of CBN by incorporating the Hall-Petch Effect, which describes the "tendency for hardness to intensify as grain size is decreased". In addition, carbon boron nitride's chemical resistant and strong thermal stability properties make it well-suited to machine ferrous materials that cannot be machined by electroplated diamond tools.

What are Metal Bond Grinding Wheels and What Benefits Do They Offer?

Extensively used in manufacturing diamond grinding wheels, metal bonds are manufactured utilizing three different processes: cold press, semi hot press and hot press modes.

Extensively used in manufacturing diamond grinding wheels, metal bonds are manufactured utilizing three different processes: cold press, semi hot press and hot press modes.

Cold press mode involves pressing the transition layer (no diamonds) and the working layer (with diamonds) of selected diamond portions to forms that on the body of the grinding wheel. These segments are then allowed to interconnect with the grinding wheel's body via slots or teeth. Finally, cold press grinding wheels are placed into sintering furnaces where they are sintered without press.

The semi hot press mode improves on the cold press mode by complementing the sintering process. While grinding wheels are sintering in a furnace, applicable molds are applied and minimal to moderate pressure is added. However, any pressure applied is significantly lower than the amount of pressure applied in hot press mode.

Hot press mode directly sinters diamond particles in molds under preset pressure levels in induction units. Diamond segments are then affixed on the grinding wheel using high frequency laser welding, high frequency welding or mosaic methods of mechanical welding.

Metal bond grinding wheels are produced when powdered metals or compounds containing cubic boron nitride or diamond are sintered on the wheel, resulting in exceptionally strong tools that maintain shape during rigorous use. In addition, metal bonding extends the life of grinding wheels by reducing the need for repeated dressings and continues being productive longer than market-brand super abrasives.

Benefits of Using Metal Bond Grinding Wheels

Because metal bond grinding wheels are sintered with cobalt, copper, mill, silver or stanum powder, they work exceptionally well on a variety of surfaces (glass, refractories, ceramics, silicon, semi-conductors and quartz).

Whether used for tool cutting, glass grinding, ceramic grinding or form cutting, metal bond grinding wheels provide the longest, most superior quality of service before any type of maintenance is needed.

Metal bond offers the ability to perform outstanding interrupted cuts while retaining the tool's original dimensions even during the most energetic grinding actions, including centerless, cylindrical, creep feed, deburring and cutoff applications.

Although resin bonds are more commonly used than vitrified or electroplated bonds, these bonds do not offer the hardness or wheel retention properties exhibited by metal bond grinding wheels.

As one of the most frequently seen machines in manufacturing plants requiring grinding applications, centerless grinders especially benefit from metal bond grinding wheels because of the slow, precise pace of material removal method demanded of these machines. Additionally, super abrasive centerless grinders necessitate powerful wheels such as metal bond grinding wheels that can effectively make predetermined alterations to products while reducing quality control issues that may arise if lesser quality wheels are used.

Continental Diamond Tool Corporation has been producing Metal Bond products since it was founded in 1973. If you are looking for a custom metal bond wheel, contact our experienced team of product engineers today.

40 Percent Improvement for Carbide Grinding with CDT Wheels on a Studer CNC Grinder

Check out how our engineers were able to add value to carbide grinding using Studer CNC grinders with a custom vitrified grinding wheel by CDT.

“Continental Diamond Tool knows grinding wheels … give them a problem and they tackle it.”

Continental Diamond Tool recently had a customer looking to replace the grinding wheel on their Studer CNC grinder. They were searching for a modern solution that would be compatible with both their newer and older CNC grinder models. With this upgrade, they hoped to reduce their cycle times and increase utilization of their capital equipment.

CDT proposed a transition to a diamond wheel for carbide grinding, and it was determined that our newly formulated vitrified diamond grinding wheel would accomplish their goals in this circumstance. Our engineers customized the core material to improve vibration damping characteristics. We also dynamically balanced the wheel allowing for improved start-up and wheel performance.

After extensive testing of the grinding wheel on their new programmable, variable speed Studers, with the same parameters as the previous competitors wheel, they slowly increased feeds until they reached the optimized 40% cycle time reduction with great success.

With the older Studers, our team ran into a complication. Because those machines use a pulley driven system, the grinders did not have the desired 6500 SFPM for vitrified diamond included. When hurdles like this arise, we meet those challenges head on. The solution to purchase a new pulley size allowed the older Studers to achieve the optimal speed for 40% cycle time efficiencies.

Besides gaining efficiency, the new wheel has extended our customers profile and form capabilities, adding Straight 1A1, Anglehead 1E1, Slotting/Groove, Face 6A2, and ID 1A8 styles. With these new capabilities our customer has been able to increase their through-put by 40% or more.

Additionally, because their old Studers are performing like new with extended capabilities, the customer will be able to delay the replacement of these old CNC grinders. At $450,000 a machine, this is a significant benefit.

Our next project will extend rotary dressing capabilities to their old Studer CNC grinders. They currently off-line dress both their current grinding wheels every other day on these older machines. Their newer Studers have rotary dressers that eliminate off-line dressing. Once rotary dressing is implemented on all their machines, it will greatly reduce their maintenance downtime.

The results from this custom project have been impressive with added value in multiple steps of the process summarized below:

· Reduced cycle times more than 40%

· Increased through-put by more than 40%

· Increased utilization of capital equipment

· Opened the door for the elimination of off line dressing

At CDT, we value our relationship with loyal customers. One of the key aspects of working with them has been our ability to expedite orders when needed and improve product performance and ultimately add value to the bottom line. When we are familiar with a company's unique process, we can often compress our four week standard lead-times to deliver in as little as one week. We can also organize blanket orders with scheduled releases.

When we asked their CFO why they chose CDT for their grinding wheels, he said, "Continental Diamond Tool knows grinding wheels, and their team is always innovating. Give them a problem and they tackle it — with excellent service, quality, and follow through."

It was a pleasure working on this project, and we're always happy to be of service!

Preparing CBN Wheels for Use

Preparing CBN wheels for use requires a bit of effort up front, but will give you long-term benefits that are immeasurable.

Superabrasive grinding wheels, such as diamond and CBN wheels require a little work and effort to set up and make them ready for use. This involves three main steps mounting, preparing (truing) and dressing the wheel so that they work as they should and give you the best possible grind. All three steps are important, but none so much as truing your CBN wheel.

What is Truing?

Truing allows for the face of the CBN wheel to be presented to the work piece properly and give you the best possible performance. After all, a wheel that is untrued can provide a surface finish, stock and removal capability that is undesirable. If you go through the truing process, and choose the right options based on your particular device and the product you are working with, you will get the highest possible performance of your grinding wheel. Additionally, the wheel life will be greatly reduced costing you much more effort and cost in the long run.

The Truing Process

The truing process occurs after you have already hand mounted your CBN wheel to the minimum runout. There are a number of techniques you can utilize to obtain the maximum truing level. Two of the most common include:

1) Multiple point (14 - 40 mesh) or impregnated (40 - 100 mesh or finer) diamond-type dressing tools.

Offers 0005" infeed for each pass (.01MM)

Not recommended for single point & cluster diamond tools

Finer mesh diamond - This technique allows better initial work piece finish

2) Truing brake or motorized dresser

Coarse grit (ranging from J to M hardness)

Silicon carbide or aluminum oxide wheel

001” Infeed per pass (.025MM)

You will apply the truing device to the wheel until contact is made with the entire face of the CBN grinding wheel. Whenever it is possible, you want to use flood coolant as this will extend the life of the CBN wheel. Heavy-duty water-soluble oils will also help add life.

It is important to remember that a resin-bonded wheel is not necessarily ready to go after it has been trued. Properly dressing it is very important as well. If you do not work through all the steps of the process, you will not get the best possible results and you may find yourself changing your wheel again much sooner than you planned to in the future.

Taking the proper preparation steps with your CBN wheels is not necessarily the easiest part of the grinding process, but it can make a big difference in the effectiveness of your wheels as well as with helping them to do their job for a longer length of time. For most factory and workshop applications, it is worth the effort and cost up front. After all, a CBN wheel is one of the most important tools you use on a daily basis, so why not take the time with the process?

Tips To Solving Wheel-Related Grinding Problems

When there are problems with a ground surface finish, when productivity is low, or if costs are too high, the fault may lie with the grinding wheel. Changing the grit, wheel feeds and speeds, or coolant application may be the solution, depending on the precise nature of the problem.

Grinding problems show up in two ways: in the appearance of the workpiece and as cost or productivity issues. After verifying that the grinding machine isn’t at fault, attention should turn to the grinding wheel.

Appearance problems divide into poor surface finish, chatter, and burning. Cost and productivity issues are short wheel life, slow cutting, and the wheel not cutting.

APPEARANCE ISSUES

Poor finish

Grinding is a multi-point cutting process, but down at the microscopic level it’s little different to a single point operation like turning. Viewed this way, it’s easy to see how surface finish is affected by the same factors: the more material removed by each grinding point, bigger the individual chips and the rougher the surface.

The solutions are:

Select a finer grit size

Reduce the relative speed of wheel and workpiece

If grinding wet, it might also be that the coolant is not removing chips from the workpiece/wheel interface. It's also possible that the wheel is being dressed excessively, creating grinding points standing too proud of the wheel surface.

Chatter

Recognizable by a distinct pattern on the workpiece, and often audible, chatter has many causes. If initiated by a vibration in the machine – possibly some kind of resonance – the solution is to vary the grinding speed. Try going 10% faster or slower to remove the forcing excitation.

Wheel-induced chatter occurs when an out-of-true grinding wheel acts as an excitation source. In this case the wheel should be trued carefully. Also check it isn’t slipping on its mount. A detailed discussion of chatter is available at the Abrasive Engineering Society website.

Burning

Machinists use this term to mean thermal damage. It can range from cosmetic discoloration to changes in workpiece hardness and possibly the creation of distortion-inducing internal tensile stresses. Burning is far more common when grinding dry, although can still be experienced in wet grinding if there isn't enough coolant flow to carry away the heat. “Burn Awareness”, originally published in Cutting Tool Engineering, December 2000, provides more information.

Burning can occur if the wheel is glazed or loaded, so there is more rubbing and hence more friction, by trying to push the wheel through the workpiece too quickly, or by using a wheel that’s too durable.

Solutions are:

Dress the wheel with a dressing stick

Reduce the feed rate or the relative velocity between wheel and workpiece.

COST AND PRODUCTIVITY ISSUES

Wheel life too short

This can be caused by:

Insufficient coolant

Dressing too often

A wheel that's either too hard or too soft for the workpiece (so it loads up or wears away too quickly)

Wheel speed too low

Slow cutting

Usually caused by feeds and/or wheel speeds that are too low, the solution is to grind as fast as possible without burning.

Wheel not cutting

This happens when the wheel is glazed by truing. The solution is to dress the wheel lightly until the grit opens up.

THINK LOGICALLY

Most grinding problems can be solved by relating the fault back to basic principles. Picture material being removed by individual cutting points and a solution usually emerges.

Supplier to Rolls Royce Creating Additional Jobs

Consort Precision Diamond, U.K. manufacturer of sophisticated cutting tools for Rolls Royce and other automotive and aerospace companies, is to create 23 new jobs. Consort is a subsidiary of Continental Diamond Tool Corp.

Consort Precision Diamond, the Continental Diamond Tool subsidiary that specializes in Rotary Diamond Dressers, was recently featured in the Daily Post in Wales. Read the article below or link to the Daily Post website here.

Supplier to Rolls Royce Creating Additional Jobs

BY OWEN HUGHES, Business Correspondent | Daily Post

A company that manufactures sophisticated cutting tools for Rolls Royce and other automotive and aerospace companies is to create 23 new jobs.

Economy Minister, Ken Skates (pictured) visited Consort Precision Diamond in Kinmel Bay, Conwy to discuss the expansion plans, which will be supported by £200k from Welsh Government.

The Minister also spoke to the company’s management team about the types of challenges they are facing in the run up to Brexit, and urged them to take advantage of the range of support offered to Welsh business to help them prepare and build resilience ahead of Brexit.

Ken Skates said: “I am delighted that the Welsh Government is supporting Conwy based Consort Precision Diamond in its plan to expand its facilities and create an additional 23 highly skilled jobs at Kinmel Bay.

“The support from Welsh Government will help fund the first phase of a five year plan that will see Consort Precision Diamond building a new premises and increasing its head count to just shy of 170.

“It was also good to speak to the company about its Brexit preparations and to ensure they are aware of, and are accessing the full range of Welsh Government support.

“Consort Precision Diamond actually exports extensively to markets outside of the EU, meaning that it is a stronger position to deal with the changes and challenges that Brexit will bring.

“I would urge any business in Wales to access our comprehensive range of exporting support and advice so they can put themselves in the strongest possible position to navigate the journey ahead.

“Of course we know that what business really needs, and continues to call for, is certainty.

“For our part we will keep pushing the UK Government to take No Deal off the table and work to secure a Brexit that protects Welsh jobs and our economy.”

Source: https://wales247.co.uk/rolls-royce-supplier-creates-23-new-jobs-with-welsh-government-support/

How to Keep your Grinding Wheels Performing Every Time

Properly dressing your grinding wheels is an important step in helping them to work as they should.

Grinding wheels are a very important tool in many factory and shop situations. They can be used for any number of projects; because of this, they tend to become something that are taken for granted. You expect that when you go to the shop that the grinding wheels will work as intended.

However, there are a number of issues that can occur that prevent the wheels from grinding as they should. While some of these problems are big and require a replacement wheel, others are reparable. One of the most common problems is a wheel that is not providing as heavy of a grind as it should.

Commonly, new wheels may not have the same grinding power as wheels that have been “broken in” and used for some time. As such, it is important to understand the concept of dressing grinding wheels.

To get the best cutting performance from your grinding wheel it is important that the wheel have a sharp abrasive grain with cutting points that are well exposed and able to connect with the piece with which you are working.

The ultra-hard abrasive crystals often used in grinding wheels will remain sharp simply through the process of grinding itself. Essentially, the wheels will slowly expose further crystals and you will not need to continuously dress the wheel. This is one of the biggest benefits of these superabrasive grinding wheels.

However, one problem is when you are working with new wheels. Usually these wheels have a smoother grinding surface. This occurs because the crystals and the surrounding bond are still flush to the edge of the cutting surface. If you try to operate a wheel without first dressing it, you will find performance is lacking. This is called “loading.” A wheel that is loaded will have poor cutting performance and may even cause some burning to your work piece.

This is where dressers come in. Diamond dressing sticks or rotary diamond dressers (also known as diamond rolls) are supplementary tools that keep your wheel operating at peak performance.

Dressing your superabrasive grinding wheel enhances grain exposure and brushes away some of the bond so that the wheel will work as it should. However, it is important that you choose the right type of dressing for your wheel to get the performance you desire. Some of the qualities you should consider with your grinding wheel dressing include:

Hand held aluminum oxide or silicon carbide stick

Soft (G, H hardness)

Fine grit (200-400 mesh)

Another strategy is to lower the RPM of the spindle, at least temporarily. This will open the wheel quicker and expose the abrasive surface for a more open surface. Then, you can increase the RPM in the future when the abrasive surface has been properly dressed and exposed.

While dressing your wheel is often something that only occurs when the wheel is new, it is possible to experience burning and poor cutting even on an older wheel. If this happens, you can simply use the same stick and technique to re-expose the surface and reopen the wheel.

As you can see, there is a lot to think about when you are first setting up your grinding wheel or if you are working with a wheel that does not seem to offer the best performance. It is possible to get the performance you desire it just takes a little work and effort up front!

Hardness Matters. Best Materials for Drilling, Cutting and Grinding

Superabrasives are split into two categories: CBN for use with ferrous material, and diamond for almost all other materials. At only half the hardness of a natural diamond, CBN is the only other material besides synthetic diamonds that is hard enough to be considered a superabrasive.

A natural diamond is the hardest material on the Knoop Hardness Scale, as is well known. It is considered a superabrasive, and has a long list of things it is regularly used to drill or otherwise shape. Glass, plastic, cemented carbide, ceramics, fiberglass, electronic components and materials, and titanium alloys are just a sampling of the things a diamond can cut. This is true whether the diamond is natural, manmade, or polysrystalline, as all three of these diamond types top the Knoop Hardness Scale. This means that even non-natural diamonds are harder than anything else except a natural one.

Right after the diamonds comes the Cubic Boron Nitride (CBN). This measures at nearly 5,000 on the Knoop Hardness Scale (compared to the 10,000 for a natural diamond, for comparison). At only half the hardness of a natural diamond, CBN is the only other material besides synthetic diamonds that is hard enough to be considered a superabrasive.

Everything else on the Knoop Hardness Scale is less hard than natural and synthetic diamonds and CBN. This means these things can cut through nearly everything else. The vast difference between the hardness of a natural diamond and the hardness of CBN shows just how relatively soft everything else on earth is in comparison to a natural diamond. If it wasn't for CBN, there would be no other super abrasive at all.

Superabrasives are split into two categories: CBN for use with ferrous material, and diamond for almost all other materials. Conventional Abrasive grinding wheels are also split into the same two categories. Silicon Carbide is known to chemically interact with ferrous materials making it less than ideal for such materials. Aluminum Oxide, despite being somewhat softer than Silicon Carbide, does not have chemical reactivity with Ferrous materials, and is therefore a better choice for these materials.

So the question becomes which is the better choice; conventional abrasive or superabrasive grinding products for your application? In general, superabrasive grinding wheels can provide 100-300 times the grinding wheel life when compared with conventional abrasives due to their higher hardness values, while only costing 10-30 times the wheel price. However, significant other variables have to be considered when determining which type of grinding wheel is best for your application. These include the machine/grinder, dressing of the grinding wheels, work piece material properties, coolant type and delivery, etc…..

Please contact one our experienced engineers to help evaluate your grinding process today to see if superabrasives are the ideal solution for your grinding application.

CDT Now Offering Same Day Shipping on Select High Performance Grinding Wheels for the Cutting Tool Industry

If you are in the cutting tool industry and are interested in gaining a competitive edge with CDT's GL™ Series grinding wheels, contact our knowledgeable team of service techs today.

Last year Continental Diamond Tool Corporation introduced its Resin Hybrid Bond — custom formulated grinding wheels with a winning combination of durability, finish, and performance.

The Resin Hybrid Series is the superior option of superabrasive diamond and CBN grinding wheels for the cutting tool industry. Using the latest Advanced Bond technology, competitive trials have proven that the bond grinds up to four times quicker without losing the wheel edge. Flute from solid, regrind, gash and end work, and relief.

Resin Hybrid Bond is not your standard “one size fits all.” This bond is tailored to specific grinding applications, providing the highest quality tool with the most efficient performance. Its unique properties offer key advantages to the CNC Tool and Cutter Grinder in many ways:

Free cutting action with superior form retention and surface finish

Self sharpening bond lengthens wheel life and dressing interval

High material removal rate with high temperature stability

Maximum heat dissipation with low and constant power consumption

Optimal wheel profile stability lowers costs due to wear

Previously cutting tool manufacturers had to commission custom-designed Resin Hybrid wheels to get all these benefits. Now CDT is stocking our most popular shapes and sizes specifically tailored to cutting tool manufacturing at affordable, off-the-shelf prices. CDT wheels are compatible with most of the cutting tool industry's leading CNC Tool and Cutter Grinder machinery.

If you are in the cutting tool industry and are interested in gaining a competitive edge with CDT's Resin Hybrid Series grinding wheels, contact our knowledgeable team of service techs today. Tell us your requirements and we will check our inventory for availability or provide you a custom quote. Wheels in stock ship the same day!

Or call 800-443-6629.

Care and Maintenance of Diamond Wheels

A few simple steps to care for and maintain your diamond wheels will allow you to get the performance and durability you expect from them.

Diamond wheels provide the maximum performance and high-speed cutting on demanding materials. Proper care and maintenance will ensure that the wheel gives the superior results for the maximum time. The steps are not difficult and well worth the effort.

Installation

Make sure that spindles, back plates and flanges are always clean before installing a new wheel. Use a dial indicator to check that the rotation of the wheel is within 0.0005 inch, 12.7 microns, of true. Tighten the flanges once the wheel is true and double-check tightness before use.

Diamond cutting wheels should only be used to make straight cuts. Twisting or jamming the wheel can cause fatigue and segment loss. Excess pressure should not be applied when making cuts.

When performing any cutting or grinding process, all work materials require firm support. Excess overhang should be avoided; even slight tilting can create an angled cut.

Feed and grinding speed

Material must be fed into the wheel at the appropriate speed. A feed rate that is too fast will cause chatter and vibration. This will result in a poor cut and possibly damage the cutting edge of the wheel.

Diamond wheels work best at speeds between 5,000 to 6,000 surface feet per minute. Running at lower speeds can lead to glazing.

Dressing

Using the wrong cutting wheel, one with a bond that is too hard for the working material, will create glazing. The easiest way to avoid this is using a blade that is matched to the material. Dressing the blade is a maintenance technique, but dressing does slow down production and reduce the life of the wheel.

Dressing a diamond wheel cleans the build up of debris from cutting operations that block the abrasive surface. The resurfacing restores the sharp abrasive edges of the diamond coating. A dressing stick, normally aluminum oxide or silicone carbide, is used to cut through or remove the debris and expose new diamond material.

Make an arrow mark on the wheel showing the rotation direction the first time and always dress the wheel with it spinning in the same direction. Dressing a wheel in both directions will destroy it.

Dressing is accomplished by simply making a straight cut through the dressing stick or bar. Cut off a thin section per pass. Only one or two cuts through the stick should be required.

If a dressing stick is not available, a section of asphalt can be used. Make a few cuts into the asphalt and the blade should be clean.

Overheating

Coolant should be used for maximum results. The coolant needs to spray to contact where the cutting wheel and material meet. A weak soluble oil solution may be used to reduce corrosion.

If dark streaks form along the sides of the cutting edge, the wheel is being overheated. Excess heat can cause the wheel to break apart. If dry cutting is being performed, allow the wheel to cool for about 10 seconds for every 30 seconds of cutting operation.

Use the right grade wheel, designed for the material to prevent injuries from reactive force or throw back. Never use a wheel that shows signs of fracture, fatigue or broken segments.

Industrial Diamond Facts

Find out about industrial diamond shapes, quality and sizes as well how they are used in industrial settings.

Diamonds are used for many industrial settings due to the fact that they are the hardest substance known. Diamonds are a crystalline form of carbon, capable of assuming a variety of shapes, sizes and qualities and are used for grinding, cutting, drilling, polishing and as an abrasive in industrial applications. Although diamonds have a high cost initially, they often cut down on the total labor cost of industrial projects due their efficiency for cutting and grinding.

SIZE AND QUALITY

Diamonds used for industrial purposes vary widely in cost which is based on two factors--size (determined by carat weight) and quality. One carat is equal to 200 milligrams of 1/5 of a gram. Each gram represents five carats. A carat is further defined as having 100 points (the smallest unit of measure in the carat system). Therefore .10 equals 1/10 of a carat, 1.5 equals 1 1/2 carats.

Diamond quality is difficult to assess, determined by highly technical factors representing the considered judgment of a trained diamond expert. For industrial purposes, the best way to judge diamond quality is by performance. The better quality a diamond is, the more structurally sound each individual crystal will be. High-quality diamonds have better shape definition, allowing for longer service and quality dressing action desired on the grinding wheel.

SHAPES

Industrial diamonds can be shaped in a variety of ways as shown below:

New Haven Company Plans to Add 150 Jobs

Continental Diamond Tool is continuously growing and plans to add 150 new jobs by the end of 2023.

by ROSA SALTER RODRIGUEZ | The Journal Gazette

Monday, October 15, 2018 — Continental Diamond Tool, New Haven, plans to invest $5.5 million in real estate improvements and new equipment and more than double its workforce, according to an application for declaration as an economic revitalization area and tax abatements.

That would mean adding about 150 jobs, the application says.

The company last year moved from a facility at 1221 Hartzell St. to 10511 Rose Ave., both in New Haven. Now, the company is outgrowing that building, said Brian Yoh, New Haven's director of planning and economic development.

Plans are to add 15,000 square feet to it at a cost of $1.3 million.

"They are a very, very successful company," Yoh said Monday. "They're having phenomenal growth."

The equipment investment includes $3.575 million in manufacturing equipment and $625,000 in research and development and information technology equipment, according to the application.

Created will be 146 full-time manufacturing jobs at an average salary of $40,000 and four full-time sales positions at an average salary of $56,000. The hiring would be done by Dec. 1, 2023.

Four new part-time janitorial jobs at an average salary of $7,500 and six part-time manufacturing jobs at an average salary of $15,500 are also listed.

The company will pay at least 70 percent of the cost of eligible employees' vacation, sick leave, holidays, health and life insurance and pension benefits.

The company now has 135 employees and a payroll of $7.2 million. The additional employees would add $6.025 million in payroll by Dec. 1, 2023.

The building construction was planned to begin late last month and be finished by April, the application states. Equipment installation would begin then and go through December, 2023, the document states.

The company makes diamond and CBN superabrasive grinding wheels. Company officiaIs did not list gross sales or the company's three largest customers and suppliers, as the application requests.

If the application is approved, the company will qualify for 10-year abatements which would save it $194,266 in real estate taxes and $237,059 in business personal property taxes for a total of $431,325.

The New Haven Council will have a public hearing on the measure at 7 p.m. Oct. 23 at city hall, 815 E. Lincoln Highway.

Source: http://www.journalgazette.net/news/local/20181015/new-haven-company-plans-to-add-150-jobs

A Concise Guide to Single Point Diamond Dressers

Learn about diamond classifications and 10 tips for using single point diamond dressers.

Problematic grinding performance typically arises as a consequence of improper dressing. Choosing the correct diamond quality classifications greatly improves the expected quality of finished products. Moreover, the number of settable points will contribute heavily to acceptable dressing standards.

Classifications of Diamond Qualities

Grade A quality diamonds provide four+ settable points--smooth-surfaced octahedron or dodecahedron.

Grade B quality diamonds provides three+ settable points--possibility of inclusions, although they do not disturb the diamond's integrity.

Grade C quality--two+ settable points exhibiting blockish structure with superficial irregularities. This grade is the most common grade used in tool rooms.

Grade D quality--less than two settable points. Grade D's may have defects around less defined points.

Grade E quality--one settable point, "utility" grade diamond typically presenting cracks and other flaws.

Grade U quality--one settable point, "utility" grade cube-shaped diamond with an opaque surface

10 Tips For Using Single Point Diamond Dressers

1. Extend the life of a single point diamond dresser by inclining the tool at a 10 to 15 degree angle to the wheel radius. Point the tool in the rotation direction of the grinding wheel to maintain a consistently sharp point.

2. When dressing with Polycrystalline (PCD), grit, diamond single points or arbitrary stone tools, the infeed has to be .001 since a diamond dressing tool inevitably pulverizes the vitrified bond. Anything higher than .001 will cause cracking into the wheel--as much as .009 deep--that forces the bond to degenerate. In addition, gullets develop that produce loading by catching chips and overheating the wheel. Consequences of excessive infeed are chatter, bounce, bad finish and burn.

3. Sharply-tipped, crystal octahedrons should be utilized for straight dressings. For 46 grit and 60 grit wheels, crystal octahedrons shaped in a gothic style work well. Points associated with crystal octahedrons stay sharp if you turn the tool six to 12 indexes every revolution, or as necessary.

4. Make sure to use enough coolant to moderate dressing temperature, otherwise overheating occurs which may chemically transforms diamond into graphite. Diamonds will also suffer cracking if subjected to large temperature gradients.

5. The objective of dressing is to generate and expose novel, superficial cutting edges on the wheel. Single point diamond dressers achieve this objective by shattering existing gravelly grains and facilitating the emergence of desired abrasive particles. Dressing increases in-feed as well as feed and must be performed regularly to maintain optimal grain protrusion and grain edge sharpness.

6. Always begin dressing at the center of the wheel, which is the biggest diameter. Starting a dressing procedure at a wheel's side will probably result in shattering or even destroying the highest quality diamonds.

7. To prevent wheel taper, place the single point diamond dress as close as possible to the grinding area.

8. Grinding wheel grain sizes are contingent on longitudinal feeds, which significantly influences the structure of the surface of a grinding wheel. Additionally, reduced feed rates will predictably provide finer, more desirable surfaces.

9. Rotate the dresser 20 to 40 degrees in the shank if a flat appears on the diamond so that the dresser maintains an optimally conical point.

10. Avoid letting the diamond erode until the shank is visible. Doing so could allow the stone to dislodge or fall out.

CDT turns 45 this month!

Continental Diamond Tool Corporation proudly celebrates 45 years of growth

Continental Diamond Tool is proud to celebrate 45 years of business! Since October, 1973, we have worked hard to provide the highest quality precision products, and excellent customer service. Here's a quick overview of how we got to where we are today:

TIMELINE

1973

Ray Viggiano opened the doors on the first 5,000 sq. ft. building

CDT began production of Metal Bond products and Diamond Dressers

1978

Launched Resin Bond product line

1984-1985

Launched Plated product line

1989

First addition to building, now totaling 8,000 sq. ft.

1997

Second addition to building, more than doubling the size to 20,000 sq. ft.

2012

Third addition to building, again doubling the size to 40,000 sq. ft.

2014

Brought Vitrified Engineer on board, and launched Vitrified products line.

2015

Fourth addition to building, increasing to 55,000 sq. ft.

2016

Acquired Sierra Diamond, a manufacturer of Metal Bond tools, in Auburn, California.

2017

Launched new GL™ Series product line

2018

Acquired Consort Precision Diamond Co. Ltd., a leading manufacturer of Rotary Diamond Dressers in the United Kingdom

Completed construction of brand-new 130,000 sq. ft. facility

Began expansion to add an additional 15,000 sq. ft.

…and still growing!

Thanks for letting us share our story with you and celebrating in our achievements. Follow us on facebook.com/ContinentalDiamondTool to watch how we continue to grow and evolve.